Introduction

Short run injection molding is an innovative manufacturing process designed for producing small quantities of plastic parts efficiently and cost-effectively. This method is particularly advantageous for businesses that require limited production runs, such as prototypes or niche products, allowing them to bring their ideas to life without the hefty investment typically associated with larger-scale production. By focusing on short run injection molding cost, companies can better navigate their budgets and understand the financial implications of their manufacturing choices.

What is Short Run Injection Molding?

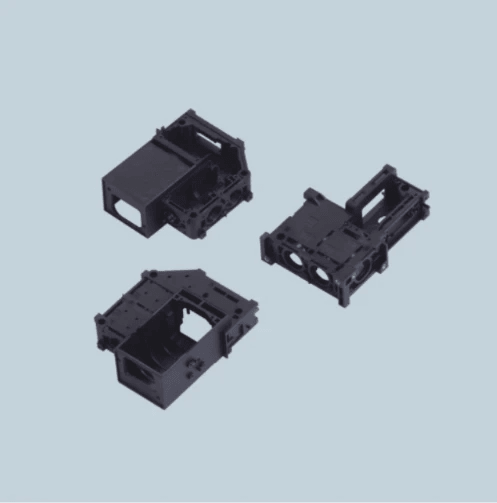

Short run injection molding refers to the process of creating plastic components in smaller batches, often ranging from a few dozen to several thousand units. Unlike traditional injection molding, which is geared towards mass production, this approach offers flexibility and rapid turnaround times while maintaining quality standards. Understanding how much does injection molding cost in a short run scenario can help manufacturers optimize their operations and make informed decisions about product development.

Factors Influencing Short Run Injection Molding Cost

Several factors significantly influence short run injection molding cost, including material selection, design complexity, and production volume. For instance, the type of resin used can affect not only the overall quality but also how much does injection molding cost per kg; some materials are more expensive than others due to their properties or availability. Additionally, understanding what is the cost per hour for an injection molding machine helps businesses gauge equipment expenses that contribute to the total pricing structure.

Benefits of Short Run Injection Molding

The benefits of short run injection molding extend beyond just cost savings; they include increased flexibility in design modifications and faster time-to-market for new products. Companies can quickly iterate on designs based on market feedback without committing to large-scale production runs upfront. Furthermore, utilizing tools like a short run injection molding cost calculator allows businesses to accurately estimate costs associated with each project while streamlining budgeting processes related to both material and labor expenses.

Understanding the Basics of Injection Molding Cost

When diving into the world of injection molding, understanding the associated costs is crucial for both manufacturers and clients. Short run injection molding cost can vary significantly based on several factors, including material selection, machine operation, and labor expenses. So, how much does injection molding cost? Let’s break it down.

How Much Does Injection Molding Cost?

The question How much does injection molding cost? is not a straightforward one; it depends on numerous variables such as part complexity, material choice, and production volume. Generally speaking, costs can range from a few hundred to several thousand dollars depending on these factors. For short run injection molding specifically, you might expect higher per-unit costs due to lower production volumes which often lead to less favorable economies of scale.

Short run injection molding cost calculators are handy tools for estimating expenses based on your specific requirements. These calculators take into account various inputs like material type and part dimensions to give you a customized estimate. Therefore, leveraging these tools can provide a more accurate picture of what you’ll be spending.

Analyzing Cost Per Kg in Injection Molding

When considering How much does injection molding cost per kg?, it’s essential to factor in both raw materials and processing fees. The price per kilogram for materials like thermoplastics can fluctuate wildly based on market conditions and supplier agreements; hence it's vital to stay informed about current rates. Additionally, the overall cost per kg will also encompass machine time and overhead expenses associated with running the equipment.

Understanding this metric helps businesses budget effectively while ensuring that they aren’t caught off guard by rising material costs during production runs. For short run projects where precision is key but volume is low, keeping an eye on this figure becomes even more critical for maintaining profitability. Thus, knowing your injection molding cost per part tied to weight allows for better financial planning.

Evaluating Machine Hourly Rates

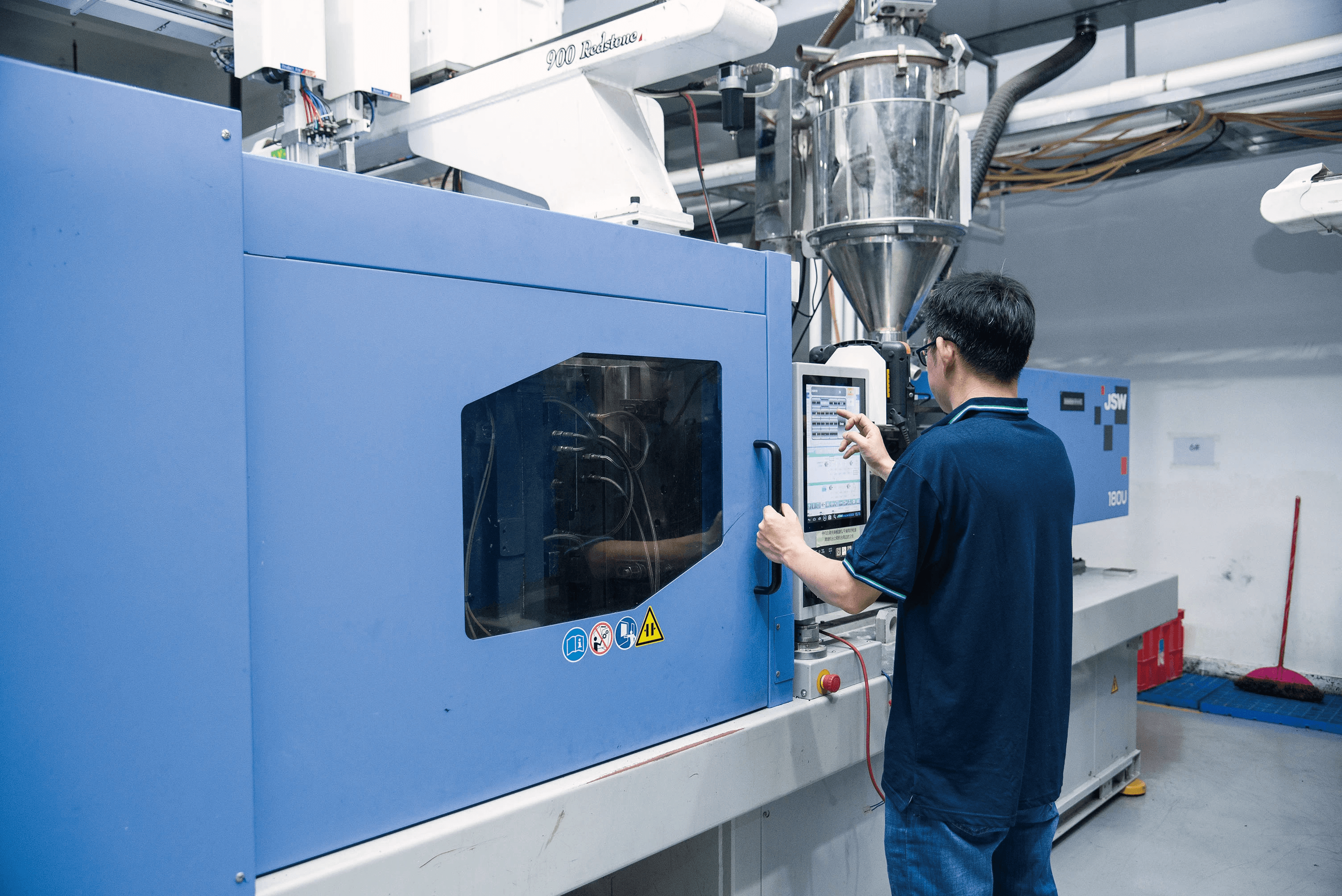

Another important aspect of understanding injection molding costs involves evaluating machine hourly rates—What is the cost per hour for an injection molding machine? This rate varies depending on machine size, technology (like whether it's hydraulic or electric), and operational efficiency among other factors. Generally speaking, larger machines with advanced capabilities tend to command higher hourly rates.

In short run scenarios where quick turnarounds are essential but volumes are limited, these hourly rates can have a significant impact on overall project costs—especially if multiple setups are required throughout production runs. The cumulative effect of machine time contributes heavily to the final short run injection molding cost; thus careful consideration of this factor can help manage budgets effectively.

Key Components of Short Run Injection Molding Cost

When diving into the world of short run injection molding cost, it's essential to break down the various components that contribute to the overall expense. Understanding these key factors can help businesses make informed decisions and optimize their manufacturing processes. In this section, we’ll explore material costs, labor expenses, and equipment maintenance costs—all crucial elements that influence how much does injection molding cost.

Material Costs Breakdown

Material costs are one of the most significant contributors to short run injection molding cost. The type of resin used directly affects not only the quality but also the price per kilogram; for instance, specialty materials often come with a hefty premium compared to standard options. On average, how much does injection molding cost per kg? This varies widely based on material choice and supplier agreements but typically ranges from $2 to $10 or more for advanced polymers.

Additionally, waste generated during production can inflate these material costs considerably; thus, efficient design and process optimization are vital. Utilizing a short run injection molding cost calculator can provide insights into how different materials impact your budget—helping you avoid unexpected expenses down the line. Ultimately, careful selection of materials is paramount in keeping your overall injection molding cost per part manageable.

Labor Expenses and Their Impact

Labor expenses play a pivotal role in determining how much does injection molding cost overall. Skilled technicians are required not just for operating machines but also for quality control and maintenance tasks that ensure production runs smoothly. Depending on your location and labor market conditions, these costs can vary significantly; however, they typically account for 20-30% of total short run injection molding costs.

Moreover, inefficiencies in labor practices can lead to increased downtime or errors—both of which drive up expenses further. Understanding what is the cost per hour for an injection molding machine is essential as it allows companies to weigh labor productivity against machine operation time effectively. By investing in training and streamlined workflows, businesses can mitigate high labor-related expenses while maximizing output.

Equipment and Maintenance Costs

The equipment used in short run injection molding has its own set of associated costs that cannot be overlooked when calculating total expenditure. The initial investment in machinery can be substantial; what is the price of 1 ton injection molding machine? Prices may range from $20,000 to over $100,000 depending on specifications and capabilities—a significant factor when considering long-term operational budgets.

Regular maintenance is another critical aspect that influences short run injection molding cost; neglecting this leads to unexpected breakdowns or costly repairs over time. Companies should budget accordingly for routine servicing as well as unexpected repairs to keep machines running efficiently without major disruptions in production schedules. Using an injection mould cost calculator helps assess ongoing equipment-related expenses accurately while providing valuable insights into optimizing operations.

The Role of Mold Design in Cost

Mold design plays a pivotal role in determining the overall short run injection molding cost. A well-thought-out mold not only ensures production efficiency but also significantly influences quality and turnaround time. By understanding how mold design affects costs, businesses can make informed decisions that optimize their budget and production processes.

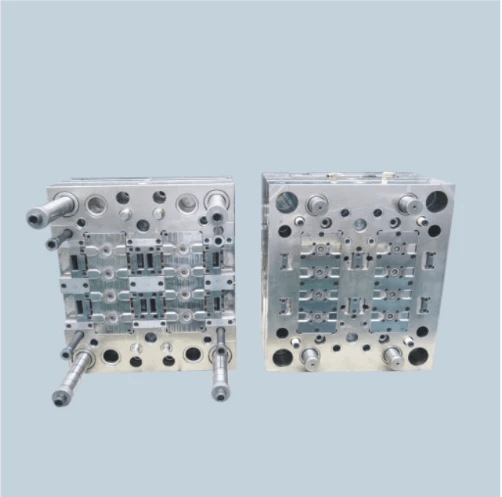

Importance of Efficient Mold Design

Efficient mold design is crucial for minimizing production costs in short run injection molding. A streamlined mold reduces cycle times, which directly impacts the question: How much does injection molding cost? When molds are designed with precision and efficiency in mind, manufacturers can produce parts at a lower cost per kg, making it an essential factor for businesses aiming to maximize profitability.

Moreover, an efficient mold design minimizes material waste and reduces the likelihood of defects during production. This helps answer another common query: What is the cost per hour for an injection molding machine? When machines operate smoothly due to effective mold design, operational costs decrease significantly, leading to improved overall financial performance.

Using the Baoyuan Team's Expertise

Leveraging the expertise of specialists like the Baoyuan team can greatly enhance your short run injection molding projects. Their knowledge in efficient mold design allows companies to navigate challenges and optimize their processes effectively. With guidance from experienced professionals, businesses can better estimate costs using tools like a short run injection molding cost calculator or an injection mould cost calculator.

The Baoyuan team understands industry best practices and innovative techniques that lead to reduced costs per part produced. By collaborating with experts who prioritize efficiency in mold design, companies can achieve significant savings while maintaining high-quality standards—ultimately answering how much does injection molding cost more accurately.

Cost Implications of Mold Complexity

The complexity of a mold has direct implications on short run injection molding costs that cannot be overlooked. More intricate designs often require advanced manufacturing techniques and longer production times, which raises questions about how much does injection molding cost per kg? As complexity increases, so do labor expenses and material usage—factors that must be considered when calculating overall project budgets.

Additionally, complex molds may necessitate higher upfront investment for tooling and maintenance over time. Understanding these factors is critical for anyone asking what is the price of 1 ton injection molding machine since complex molds might require more sophisticated machinery to accommodate their demands effectively. Therefore, striking a balance between necessary complexity and cost-efficiency is vital for successful project execution.

Utilizing Cost Calculators for Accuracy

In the world of short run injection molding, having precise cost estimations can make or break a project. This is where cost calculators come into play, providing invaluable tools for manufacturers and businesses alike. By utilizing these calculators, stakeholders can gain insights into various cost factors, helping them to answer questions like How much does injection molding cost? with confidence.

Short Run Injection Molding Cost Calculator

The short run injection molding cost calculator is a game changer for anyone involved in the manufacturing process. This tool allows users to input specific parameters such as material type, part size, and production volume to generate an estimated total cost. By considering factors like labor, machine hourly rates, and material costs, it helps answer critical questions about short run injection molding costs efficiently.

When using this calculator, it’s essential to remember that accuracy hinges on the quality of the data entered. The more precise your inputs regarding How much does injection molding cost per kg? or What is the price of 1 ton injection molding machine? the more reliable your output will be. Ultimately, this tool empowers businesses to make informed decisions about their manufacturing processes and budgets.

Injection Mould Cost Calculator Overview

The injection mould cost calculator serves a similar purpose but focuses specifically on mold design and production expenses. It provides insights into how mold complexity affects overall costs—an often-overlooked aspect when calculating short run injection molding costs. Understanding these nuances can significantly impact budgeting strategies and project timelines.

This calculator typically includes features that allow users to factor in various types of molds—be it single cavity or multi-cavity—and their respective pricing structures based on materials used and design intricacies. It’s particularly useful for answering questions like What is the cost per hour for an injection molding machine? since mold efficiency directly influences machine utilization rates and overall productivity.

By leveraging this tool effectively, manufacturers can optimize their designs while keeping an eye on potential savings in both time and money.

Accuracy in Injection Molding Cost Per Part

Achieving accuracy in determining the injection molding cost per part is crucial for maintaining profitability in any production cycle. Many variables come into play when calculating this figure—including material selection, cycle times, labor involvement, and overhead costs associated with equipment maintenance. Therefore, utilizing calculators designed specifically for these calculations can lead to more reliable estimates.

With tools like the short run injection molding cost calculator at your disposal, you can quickly assess how changes in one area—like switching materials or altering part designs—affect your overall costs per unit produced. This flexibility not only aids in budgeting but also enhances strategic planning as you navigate market fluctuations or shifts in demand.

In summary, accurate estimations derived from effective use of these calculators enable manufacturers to streamline operations while keeping a keen eye on their bottom line—a vital component when dealing with varying project scopes within short run injection molding contexts.

Case Studies on Short Run Injection Molding Costs

When it comes to short run injection molding costs, real-world examples can provide invaluable insights. These case studies highlight the variations in cost based on material choice, complexity of design, and production volume. Understanding these factors helps businesses better estimate how much does injection molding cost in their specific scenarios.

Real-World Examples of Cost Variations

One notable case involved a startup that required a small batch of custom plastic components for a new gadget. They found that the short run injection molding cost was significantly impacted by their choice of material—opting for a high-grade polymer led to an increased overall expense but ultimately improved product durability. In contrast, another company focused on using standard materials and managed to keep their costs lower, showcasing how different approaches can yield varying price points for short run injection molding.

In another example, a medical device manufacturer faced unique challenges due to stringent regulations and the need for precise specifications. Their short run injection molding cost skyrocketed due to complex mold designs and tight tolerances required for safety compliance. This highlights that while some industries may enjoy lower costs with simpler designs, others may incur higher expenses based on regulatory demands.

Comparing Different Industries' Costs

When comparing short run injection molding costs across industries, it's clear that not all sectors are created equal. For instance, the automotive industry often benefits from economies of scale but faces higher initial setup costs due to specialized molds and materials needed for vehicle parts. On the other hand, consumer electronics manufacturers frequently utilize shorter production runs which can lead them to rely heavily on accurate estimates from tools like the short run injection molding cost calculator.

Healthcare products tend to have higher per-part costs because they require more rigorous testing and validation processes before production begins; thus, understanding how much does injection molding cost per kg is crucial in this field. Meanwhile, industries like toys or household goods might enjoy lower overall expenses by leveraging simpler designs and readily available materials—making them more budget-friendly in terms of both labor and equipment costs.

Lessons Learned from Successful Projects

Successful projects often reveal critical lessons about managing short run injection molding costs effectively. One key takeaway is the importance of upfront planning; companies that invest time in mold design often see significant savings down the line when it comes to both labor expenses and machine hourly rates—knowing what is the cost per hour for an injection molding machine can help gauge this accurately.

Another lesson learned is leveraging technology such as an Injection mould cost calculator or Injection molding cost per part analysis tools; these resources empower businesses to make informed decisions regarding material selection and production strategies early in the process. Ultimately, companies that prioritize accurate estimations are better positioned to navigate fluctuations in market demand while keeping their short run injection molding costs manageable.

Conclusion

In wrapping up our exploration of short run injection molding, it's clear that understanding its cost structure is essential for making informed decisions. Factors ranging from material selection to labor expenses play a significant role in determining the short run injection molding cost. Additionally, efficient mold design and accurate calculations using tools like the short run injection molding cost calculator can help manage and predict expenses.

Recap of Short Run Injection Molding Insights

Throughout this discussion, we have delved into the intricacies of short run injection molding costs. We addressed questions such as How much does injection molding cost? and provided insights into material costs, labor impacts, and machine rates. By analyzing these elements together, businesses can gain a clearer picture of how to optimize their production processes while keeping an eye on the bottom line.

Importance of Accurate Cost Estimation

Accurate cost estimation is crucial for any manufacturing venture, especially in short run injection molding where costs can fluctuate significantly based on various factors. Understanding How much does injection molding cost per kg? or What is the price of 1 ton injection molding machine? helps companies budget effectively and avoid unexpected financial pitfalls. Moreover, utilizing tools like the injection mould cost calculator allows for precise planning, ensuring that projects remain profitable without sacrificing quality.

Future Trends in Injection Molding Costs

Looking ahead, several trends are poised to influence short run injection molding costs significantly. Advancements in technology may lead to more efficient machines that reduce the question What is the cost per hour for an injection molding machine? as operational efficiencies improve over time. Furthermore, as industries evolve and demand shifts toward sustainability, we might see changes in material sourcing that will impact both pricing structures and overall production strategies.