Introduction

In the ever-evolving landscape of medical manufacturing, micro molding medical devices has emerged as a game-changer. This sophisticated approach to injection molding allows for the creation of intricate and precise components that meet the stringent demands of healthcare applications. As a result, understanding the nuances of this process is essential for anyone involved in medical device development.

Understanding Medical Micro Injection Molding

Micro molding is a specialized form of injection molding that focuses on producing extremely small and complex parts with high precision. This technique is particularly beneficial in the medical field, where devices often require intricate designs and tight tolerances to function effectively. By utilizing advanced technology and materials, micro molding enables manufacturers to create high-quality injection molded parts that are both reliable and efficient.

Importance of Quality in Medical Molding

Quality assurance is paramount in medical molding because even minor defects can have significant consequences for patient safety and product efficacy. The rigorous standards set by regulatory bodies necessitate that manufacturers implement strict quality control measures throughout the entire injection moulding process. Ensuring top-notch quality not only enhances product performance but also builds trust with healthcare providers and patients alike.

How Top Manufacturers Stand Out

Top manufacturers distinguish themselves through their commitment to innovation, expertise, and stringent quality assurance practices in micro molding medical devices. They leverage cutting-edge technologies such as insert molding to enhance functionality while reducing production costs and timeframes. By prioritizing continuous improvement and customer satisfaction, these leaders set benchmarks in the industry that others aspire to achieve.

The Basics of Micro Molding Medical Devices

Micro molding is an innovative technique that has revolutionized the production of medical devices. By utilizing precision engineering, this process allows for the creation of intricate and miniature components that are essential in modern healthcare. Micro molding medical devices not only meet stringent industry standards but also enhance the functionality and efficiency of medical applications.

What is Micro Molding?

Micro molding refers to a specialized form of injection molding designed for producing tiny parts with high precision and repeatability. This process involves injecting molten plastic into a mold cavity that is often less than 1 gram in weight, creating micro-sized components with complex geometries. The injection moulding process used in micro molding requires advanced technology and expertise to ensure that every detail is accurately replicated, making it ideal for critical medical applications.

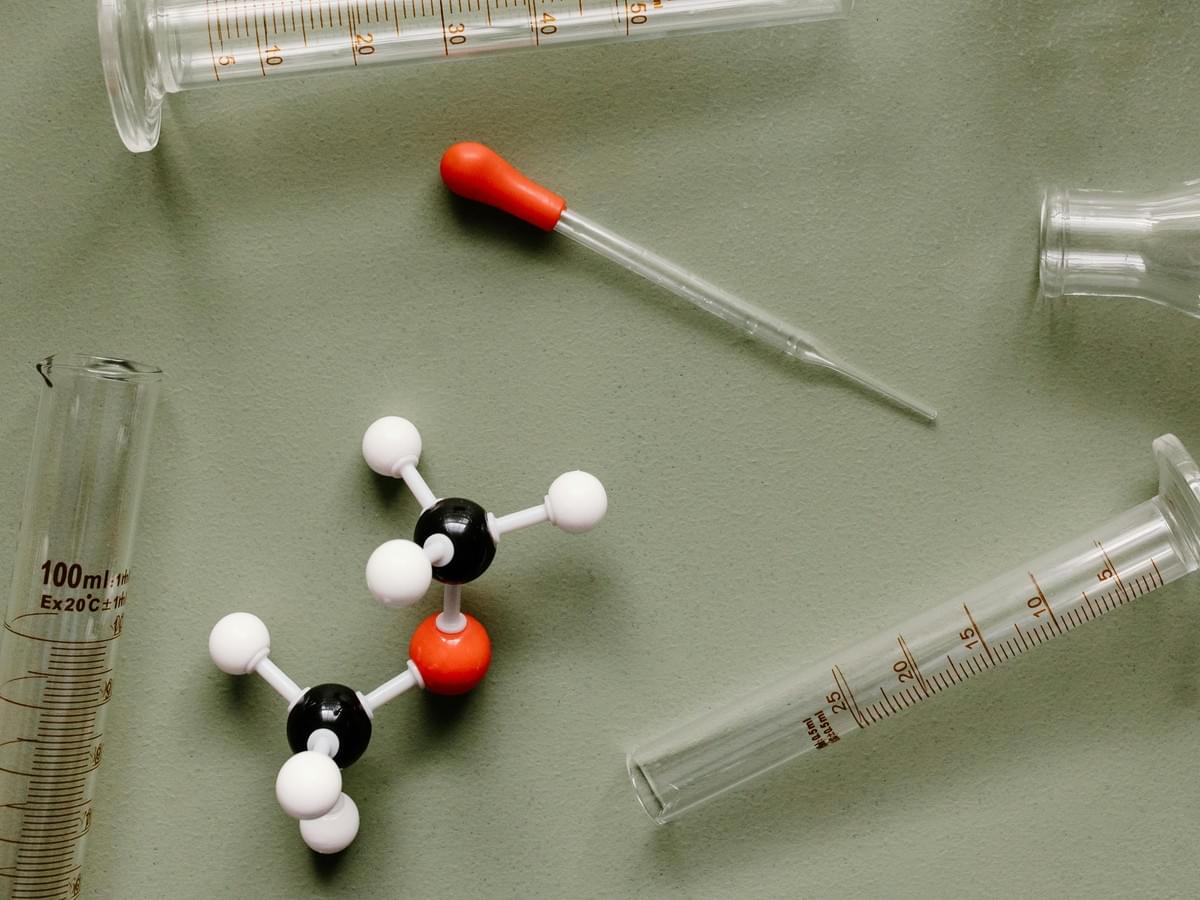

Applications in the Medical Field

The applications of micro molding in the medical field are vast and diverse, ranging from surgical instruments to drug delivery systems. For instance, micro molded components are commonly found in catheters, syringes, and implantable devices where precision is paramount. These tiny yet crucial parts contribute significantly to patient safety and treatment efficacy, showcasing how micro molding medical devices play an essential role in modern healthcare solutions.

Advantages of Micro Molding in Medical Manufacturing

One major advantage of micro molding over traditional methods is its ability to produce highly intricate designs while minimizing material waste. This not only leads to cost savings but also enhances product sustainability—an increasingly important factor in today's manufacturing landscape. Furthermore, the scalability and efficiency offered by micro molding allow manufacturers to rapidly respond to market demands without compromising on quality or performance, making it a preferred choice for many companies engaged in medical manufacturing.

The Injection Molding Process Explained

Injection molding is a fascinating and intricate process that serves as the backbone for producing micro molding medical devices. This method allows manufacturers to create precise, high-quality injection molded parts that meet the stringent requirements of the medical industry. Understanding each step in the injection moulding process is crucial for ensuring optimal results and maintaining quality standards.

Steps in the Injection Moulding Process

The injection moulding process begins with material selection, where specific polymers are chosen based on their properties suitable for medical manufacturing. Next, these materials are heated until they reach a molten state before being injected into a mold under high pressure. Once cooled, the mold opens to reveal perfectly formed parts ready for further processing or assembly.

Throughout this process, precision is paramount; even minor deviations can lead to defects in micro molding medical devices. The molds themselves are meticulously designed and crafted to ensure accuracy and repeatability in production. Following ejection from the mold, parts undergo inspections to verify they meet required specifications before moving on to secondary operations or packaging.

Role of Insert Molding in Medical Devices

Insert molding plays a vital role in enhancing the functionality of injection molded parts used in medical devices. This technique involves placing pre-fabricated components—such as metal pins or electronic circuits—into a mold before injecting plastic around them. The result is a single part that integrates multiple functionalities, reducing assembly time and improving overall performance.

Incorporating insert molding into micro molding processes not only streamlines production but also enhances device reliability by minimizing potential failure points associated with multiple components. This method is particularly advantageous in applications where space is limited and precision is critical—common characteristics of many medical devices today. By leveraging insert molding techniques, manufacturers can produce highly complex designs that fulfill rigorous industry standards.

Quality Control Measures during Injection Molding

Quality control measures during injection molding are essential for ensuring that every micro molding medical device meets strict regulatory requirements and customer expectations. These measures include real-time monitoring of temperature, pressure, and flow rates throughout the injection moulding process to detect any anomalies immediately. Additionally, regular sampling and testing of finished products help identify defects early on.

Manufacturers often employ advanced technologies such as automated vision systems to inspect molded parts for dimensional accuracy and surface quality post-production. Implementing these quality control strategies not only ensures compliance but also fosters trust between manufacturers and healthcare providers relying on their products for patient safety. Ultimately, maintaining rigorous quality standards during every stage of production solidifies a manufacturer's reputation within the competitive landscape of medical manufacturing.

The Role of Baoyuan in Medical Molding

In the competitive landscape of medical manufacturing, Baoyuan stands out as a pioneer in micro molding medical devices. Their commitment to innovation and quality has positioned them as a leader in the injection molding industry. With a focus on precision and efficiency, Baoyuan has redefined what it means to excel in medical molding.

Expertise of Baoyuan's Team

Baoyuan boasts a team of highly skilled professionals who specialize in the intricacies of the injection moulding process. Their expertise spans various aspects of micro molding, from design to production, ensuring that every project meets stringent medical standards. This wealth of knowledge allows Baoyuan to tackle complex challenges and deliver superior injection molded parts that are both functional and reliable.

The team’s experience is complemented by ongoing training and development, keeping them updated with the latest trends and technologies in medical manufacturing. This dedication to continuous improvement ensures that Baoyuan remains at the forefront of innovation within the industry. By leveraging their collective expertise, they provide tailored solutions for clients seeking top-notch micro molding medical devices.

Innovative Techniques Used by Baoyuan

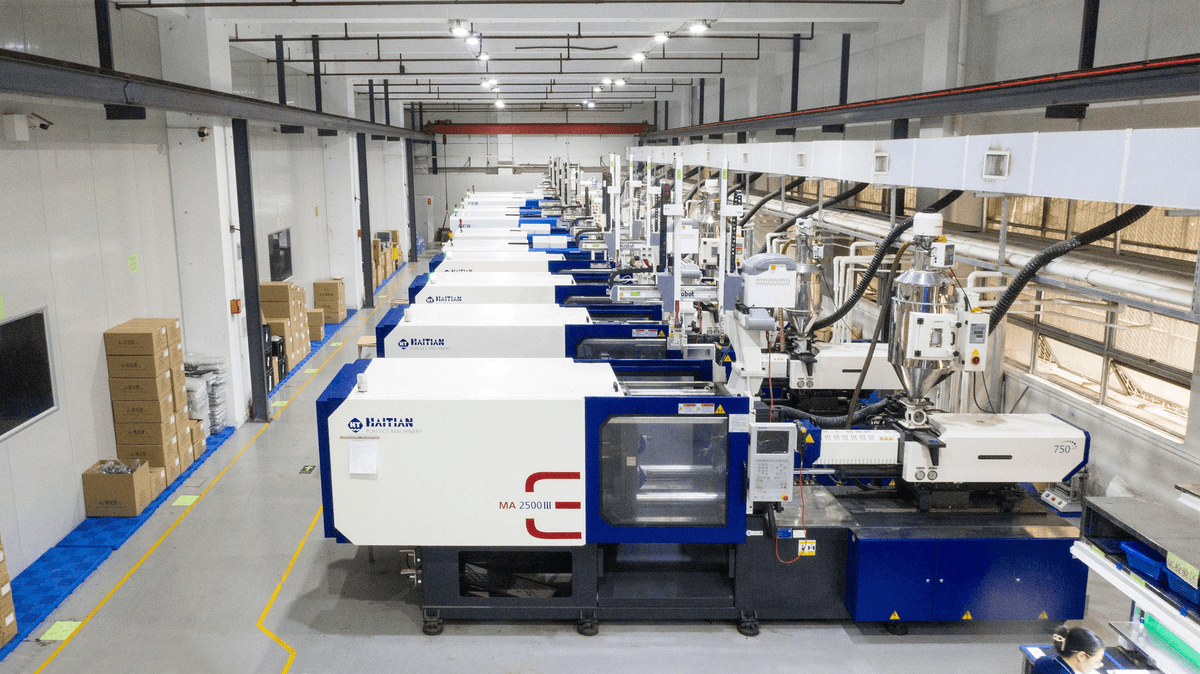

At Baoyuan, innovation is not just a buzzword; it's embedded in their operational philosophy. They employ advanced techniques such as insert molding, which allows for greater design flexibility and reduces assembly costs for complex medical devices. By integrating multiple components into a single part during the injection moulding process, they enhance functionality while maintaining high-quality standards.

Additionally, Baoyuan utilizes state-of-the-art machinery that optimizes precision during production runs, ensuring consistency across all injection molded parts. Their commitment to research and development fuels continuous advancements that push the boundaries of what's possible in medical molding over traditional methods. This innovative spirit enables them to meet diverse client needs while adhering to strict regulatory requirements.

Baoyuan's Commitment to Quality Assurance

Quality assurance is paramount at Baoyuan; it’s woven into every step of their manufacturing process for micro molding medical devices. From material selection through final inspection, rigorous quality control measures ensure that each product meets or exceeds industry standards. They implement comprehensive testing protocols throughout the injection moulding process to identify potential issues early on.

Furthermore, their commitment extends beyond compliance; they strive for excellence by continuously refining their quality management systems based on feedback and performance metrics. This proactive approach not only enhances product reliability but also fosters trust among clients relying on their expertise for critical applications in healthcare settings. Ultimately, Baoyuan’s unwavering dedication to quality assurance solidifies its reputation as a leader in medical manufacturing.

Comparing Micro Molding and Traditional Methods

In the realm of medical manufacturing, the choice between micro molding and traditional techniques can significantly impact the quality and functionality of medical devices. Micro molding, specifically designed for creating intricate parts with high precision, has emerged as a game-changer in the injection molding landscape. As the demand for smaller, more complex components grows, understanding the advantages of micro molding over traditional methods becomes essential.

Advantages of Micro Molding over Traditional Techniques

Micro molding medical devices offer several advantages that set them apart from conventional molding processes. Firstly, micro molding allows for greater design flexibility; manufacturers can create intricate geometries that would be impossible or prohibitively expensive to achieve with traditional methods. Additionally, this technique minimizes material waste, which is not only cost-effective but also environmentally friendly—an increasingly important factor in today's manufacturing paradigm.

Another key advantage lies in precision; micro molded parts exhibit superior dimensional accuracy compared to their traditionally molded counterparts. This level of precision is crucial in medical applications where even slight deviations can lead to device malfunction or failure. Furthermore, micro molding's ability to integrate multiple functions into a single component reduces assembly time and complexity—making it a preferred choice for innovative medical device designs.

Cost-Effectiveness in Medical Manufacturing

When it comes to cost-effectiveness, micro molding often outshines traditional techniques in several ways. Although initial setup costs may be higher due to specialized equipment and tooling required for the injection moulding process, these costs are quickly offset by reduced material usage and lower labor expenses associated with fewer assembly steps. The efficiency gained through streamlined production processes means that manufacturers can produce high-quality injection molded parts at a lower overall cost per unit.

Moreover, by utilizing insert molding within the micro molding framework, manufacturers can further enhance cost savings while improving product functionality. Insert molding allows for the integration of additional components during the injection process—eliminating separate assembly operations and reducing both time and costs associated with labor-intensive methods found in traditional manufacturing setups. Consequently, companies adopting micro molding practices often find themselves with a competitive edge due to their ability to deliver high-quality products at attractive price points.

Scalability and Efficiency of Micro Molding

Scalability is another significant benefit offered by micro molding when compared to traditional methods in medical manufacturing. As demand fluctuates or increases for specific medical devices, manufacturers employing micro injection techniques can quickly adapt their production volumes without compromising quality or efficiency. This flexibility is particularly advantageous in an industry where rapid prototyping and quick turnaround times are essential for staying ahead of competitors.

Efficiency is also greatly enhanced through automation within the injection moulding process used for micro molded parts; this leads to faster cycle times while maintaining precise tolerances necessary for effective functioning within medical applications. Furthermore, advancements in technology have led to innovations such as multi-cavity molds that allow simultaneous production of several identical components—drastically increasing output without sacrificing quality standards inherent in medical molding practices.

In summary, comparing micro molding with traditional techniques reveals clear advantages regarding design flexibility, cost-effectiveness through reduced waste and labor requirements, as well as improved scalability and efficiency—all critical factors driving success within today’s competitive landscape of medical device manufacturing.

Future Trends in Injection Molded Parts

The landscape of medical manufacturing is evolving rapidly, driven by innovations that enhance the capabilities and applications of injection molded parts. As we look ahead, advancements in micro molding medical devices are set to redefine how we approach design and functionality in healthcare solutions. From smart implants to precision instruments, the future promises a wave of products that capitalize on the strengths of modern molding techniques.

Advancements in Medical Device Manufacturing

The medical device sector is witnessing remarkable advancements, particularly through the adoption of micro molding techniques. These innovations allow for the creation of smaller, more intricate components that were previously unattainable with traditional methods. With an increase in demand for minimally invasive procedures, micro molding medical devices are becoming essential for developing sophisticated tools that improve patient outcomes and streamline surgical processes.

Moreover, technologies such as 3D printing are being integrated into the injection molding process to enhance design flexibility and reduce lead times. This synergy between traditional injection moulding and new manufacturing technologies enables manufacturers to create complex geometries and customized solutions tailored to specific clinical needs. As a result, companies can respond more swiftly to market demands while maintaining high standards of quality assurance.

The Impact of Technology on Injection Molding

Technology continues to play a pivotal role in transforming the injection molding landscape within medical manufacturing. Advanced software solutions for design simulation and mold flow analysis help manufacturers optimize their processes before production begins, reducing waste and improving efficiency. Additionally, automation within the injection moulding process minimizes human error while increasing precision—essential qualities when producing critical components like insert molded parts.

The integration of IoT (Internet of Things) into manufacturing systems also enhances real-time monitoring capabilities during production runs. This technology provides valuable insights into machine performance and quality control metrics, ensuring that every piece meets stringent regulatory standards without compromising speed or cost-effectiveness. With technology advancing at such a rapid pace, manufacturers who embrace these changes will undoubtedly gain a competitive edge.

Sustainability in Medical Molding Practices

Sustainability is increasingly becoming a focal point in medical molding practices as companies strive to balance innovation with environmental responsibility. The shift towards eco-friendly materials for micro molding medical devices not only helps reduce waste but also opens up new avenues for sustainable product development within the healthcare sector. Biodegradable polymers and recycled materials are gaining traction as viable alternatives that maintain performance without sacrificing quality.

Furthermore, optimizing energy usage during the injection moulding process contributes significantly to reducing carbon footprints across manufacturing facilities. Implementing energy-efficient machinery alongside lean production techniques allows companies to minimize resource consumption while maximizing output—an essential step toward achieving sustainability goals in medical manufacturing environments.

As awareness grows around sustainability issues within healthcare supply chains, manufacturers who prioritize eco-conscious practices will likely appeal more strongly to environmentally aware consumers and stakeholders alike.

Conclusion

In the rapidly evolving landscape of medical manufacturing, micro molding medical devices has emerged as a game-changer. This innovative technique allows for the production of highly intricate and precise components that are essential for modern healthcare solutions. As we’ve explored, the injection molding process offers significant advantages over traditional methods, making it a preferred choice for many manufacturers.

Key Takeaways on Micro Molding Medical Devices

Micro molding medical devices represent a crucial advancement in the production of small-scale components with high precision. The benefits of this method include enhanced design flexibility, reduced material waste, and improved efficiency in the injection moulding process. With applications ranging from surgical instruments to drug delivery systems, micro molding is paving the way for next-generation medical solutions.

The Importance of Choosing Top Manufacturers

Selecting top manufacturers in the field of medical molding is vital for ensuring product quality and compliance with stringent industry standards. Experienced companies bring expertise in insert molding techniques and rigorous quality control measures that can significantly impact patient safety and device efficacy. By partnering with reputable manufacturers, healthcare providers can ensure that they receive reliable injection molded parts that meet their specific needs.

Looking Ahead: The Future of Medical Injection Molding

The future of injection molded parts in medical manufacturing looks promising with ongoing advancements in technology and materials science. Innovations such as 3D printing integration and smart materials are set to revolutionize how micro molding is approached, leading to even greater efficiencies and capabilities in production processes. Moreover, sustainability practices are becoming increasingly important, pushing manufacturers toward eco-friendly solutions without compromising on quality or performance.