Introduction

In the bustling world of manufacturing, resin injection molding has emerged as a game-changer, revolutionizing how products are crafted. This innovative process combines the strengths of resin and moulds to produce intricate designs with remarkable efficiency. As industries evolve, understanding the dynamics of resin injection molding becomes essential for anyone looking to stay ahead in the competitive landscape.

Understanding Resin Injection Molding

Resin injection molding is a sophisticated technique that involves injecting molten resin into a mold to create various plastic components. This method not only allows for precision in design but also enhances production speeds, making it a preferred choice among manufacturers. By leveraging this technology, businesses can achieve consistent quality and intricate details in their plastic injection molding projects.

Why Choose Resin for Your Projects

Choosing resin for your projects offers numerous advantages that traditional materials simply can't match. For starters, resin injection molding provides exceptional versatility, allowing designers to explore creative shapes and patterns without compromising on durability. Additionally, the cost-effectiveness of using resin and moulds makes it an attractive option for both small-scale artisans and large-scale manufacturers alike.

The Growing Popularity of Resin Materials

The popularity of resin materials is on the rise across various sectors due to their unique properties and benefits. As industries seek sustainable solutions without sacrificing performance, resin injection molding stands out as an eco-friendly alternative to conventional plastics. This trend reflects a broader shift towards innovation in manufacturing processes, with many embracing the endless possibilities offered by mold plastic injection techniques.

Advantages of Resin in Injection Molding

Cost-Effectiveness of Resin-Based Solutions

One of the most compelling reasons to choose resin injection molding is its cost-effectiveness. The materials used in resin and moulds often come at a lower price point compared to traditional plastics, which can significantly reduce overall project costs. Additionally, the efficiency associated with plastic injection molding means that manufacturers can produce large volumes quickly, further driving down costs per unit.

Moreover, using high-quality resins can minimize waste during production processes like mold plastic injection. This not only saves money but also contributes positively to environmental sustainability by reducing excess material disposal. Ultimately, choosing resin-based solutions allows businesses to maintain profitability while producing high-quality products.

Versatility in Design with Resin and Moulds

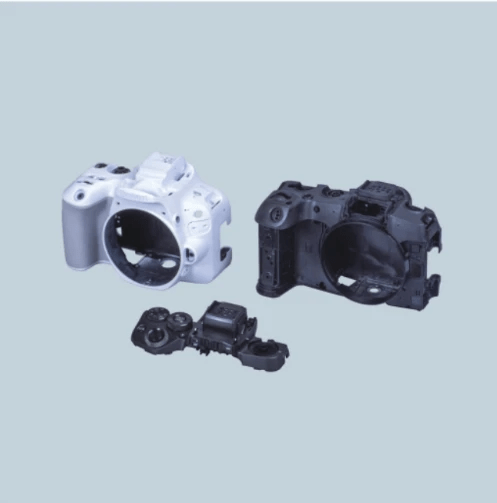

Resin injection molding shines when it comes to design versatility; it accommodates complex shapes and intricate details that other materials might struggle with. Whether you’re creating a simple component or an elaborate assembly, the adaptability of resin and moulds enables designers to push creative boundaries without compromising functionality. This flexibility is particularly advantageous for industries requiring bespoke designs tailored specifically for their needs.

Additionally, advancements in injection casting technology have made it easier than ever to create custom molds that perfectly fit your project requirements. The ability to experiment with different colors and finishes further enhances design options available through plastic injection molding techniques. In essence, if you can dream it up, chances are resin can bring it to life.

Enhanced Durability of Resin Products

Durability is another key advantage of using resin in injection molding applications; these products are designed to withstand wear and tear better than many traditional plastics on the market today. Resins exhibit excellent resistance against impacts, chemicals, and UV light exposure, making them ideal for various demanding environments—from automotive parts to outdoor equipment components. This enhanced durability translates into longer-lasting products that require less frequent replacements or repairs.

Furthermore, when combined with innovative mold plastic injection techniques, these durable resins can be engineered for specific performance characteristics tailored precisely for their intended applications. By choosing high-performance resins for your projects, you ensure not only longevity but also reliability under pressure—essential qualities in any competitive market landscape today. With enhanced durability on your side, you’ll find that investing in resin products pays off over time.

The Role of Plastic Injection Molding

Plastic injection molding is a game-changer in the manufacturing world, and when combined with resin, it takes efficiency and creativity to new heights. This process allows for the rapid production of complex parts while maintaining high-quality standards. Understanding how resin injection molding fits into this picture can make all the difference for businesses looking to optimize their production lines.

How Resin Increases Production Efficiency

Resin injection molding is known for its impressive speed, which significantly boosts production efficiency. The quick curing times associated with resin mean that manufacturers can produce more parts in less time compared to traditional methods. Additionally, using a plastic injection molding mold designed specifically for resin can further streamline operations, reducing downtime and increasing output.

Moreover, the adaptability of resin allows it to be used in various applications without compromising quality or performance. This versatility means that companies can switch between different products without needing extensive retooling of their injection molds. As a result, businesses not only save time but also cut costs associated with lengthy setup processes.

Incorporating resin into the injection casting process also minimizes waste since excess material can often be reused or recycled within the same production cycle. This eco-friendly approach not only enhances efficiency but also aligns with modern sustainability goals that are increasingly important to consumers and stakeholders alike.

Achieving Complex Shapes with Resin Injection Molding

One of the standout features of resin injection molding is its ability to create intricate designs that would otherwise be impossible or prohibitively expensive using other materials. The fluid nature of liquid resins allows them to flow into every nook and cranny of a mold plastic injection setup, capturing even the most detailed features. This capability opens up a world of design possibilities for engineers and designers alike.

Furthermore, complex shapes produced through resin injection molding often require fewer assembly steps than traditional manufacturing methods might necessitate. By creating multi-component parts in one go, companies can reduce labor costs and improve overall product integrity since there are fewer joints or seams where failure could occur.

Lastly, achieving these complex shapes does not compromise durability; on the contrary, many resins exhibit impressive strength characteristics once cured properly through effective mold design techniques. Thus, manufacturers benefit from both aesthetic appeal and functional resilience when utilizing advanced resin technologies.

The Importance of Quality in Injection Moldable Plastics

Quality assurance is paramount in any manufacturing process, but it's especially critical when dealing with injection moldable plastics like those derived from resin materials. High-quality resins ensure that final products meet stringent performance expectations while minimizing defects during production runs. Companies leveraging superior quality control measures will find themselves at a competitive advantage in today’s market.

Moreover, investing in high-quality plastic injection molding molds designed specifically for use with resins leads to better surface finishes and dimensional accuracy across batches—factors essential for customer satisfaction and brand reputation alike. When products consistently meet or exceed customer expectations due to their quality attributes derived from effective mold design practices, repeat business is almost guaranteed.

In conclusion, prioritizing quality throughout every stage of the resin injection molding process—from material selection through final inspection—ensures longevity and reliability in end products while fostering consumer trust over time.

Comparing Resin with Other Materials

Resin vs. Thermoplastics in Molding

Resin injection molding offers distinct advantages when compared to thermoplastics in the realm of molding processes. While thermoplastics are known for their flexibility and recyclability, resin provides superior durability and resistance to various environmental factors. The ability of resin and moulds to create complex shapes with precision makes it a prime candidate for applications requiring high-quality finishes that thermoplastics may struggle to achieve.

Additionally, plastic injection molding using resin can often result in lower production costs due to reduced scrap rates and faster cycle times. The versatility of resin allows for a wider range of formulations tailored for specific applications, which can be more challenging with standard thermoplastic options. Overall, while both materials have their merits, the unique qualities of resin injection molding make it an attractive choice for many manufacturers.

Environmental Impact of Resin Injection Molding

The environmental impact of any manufacturing process is an increasingly important consideration today, including resin injection molding. While some may argue that resins are less eco-friendly than biodegradable alternatives or recyclable thermoplastics, advancements in technology have led to more sustainable practices within the industry. Many modern resins are now designed with lower emissions during production and improved recyclability at the end of their life cycle.

Moreover, efficient mold plastic injection techniques can minimize waste during the manufacturing process by optimizing material usage and reducing excess scrap materials. By utilizing innovative approaches like closed-loop systems or bio-based resins, manufacturers can significantly mitigate their carbon footprint while still benefiting from the strengths of resin products in various applications. As consumers become more environmentally conscious, this shift toward greener practices will likely drive further development within the realm of resin injection molding.

Performance Benefits: Resin vs. Traditional Plastics

When evaluating performance benefits between resin and traditional plastics in plastic injection molding processes, it's clear that each material has its strengths but also limitations. Resins generally outperform traditional plastics when it comes to mechanical strength and thermal stability; they can withstand higher temperatures without deforming or losing structural integrity under pressure—key factors for demanding applications like automotive parts or electronics housings.

Furthermore, products made from resin exhibit impressive chemical resistance compared to many conventional plastics which may degrade when exposed to certain substances over time. This enhanced durability ensures longer product lifespans—a crucial consideration for industries focused on reliability and safety standards—making resin an appealing option over traditional plastic alternatives.

In conclusion, while both materials have their place in manufacturing processes such as mold plastic injection techniques or injection casting methods, understanding these comparisons helps businesses choose wisely based on project requirements.

Techniques in Injection Casting with Resin

When it comes to resin injection molding, mastering the techniques of injection casting can significantly enhance product quality and production efficiency. Understanding the nuances of mold plastic injection is crucial for achieving optimal results. With the right practices in place, manufacturers can unlock the full potential of resin and moulds, producing high-quality components that meet market demands.

Best Practices for Mold Plastic Injection

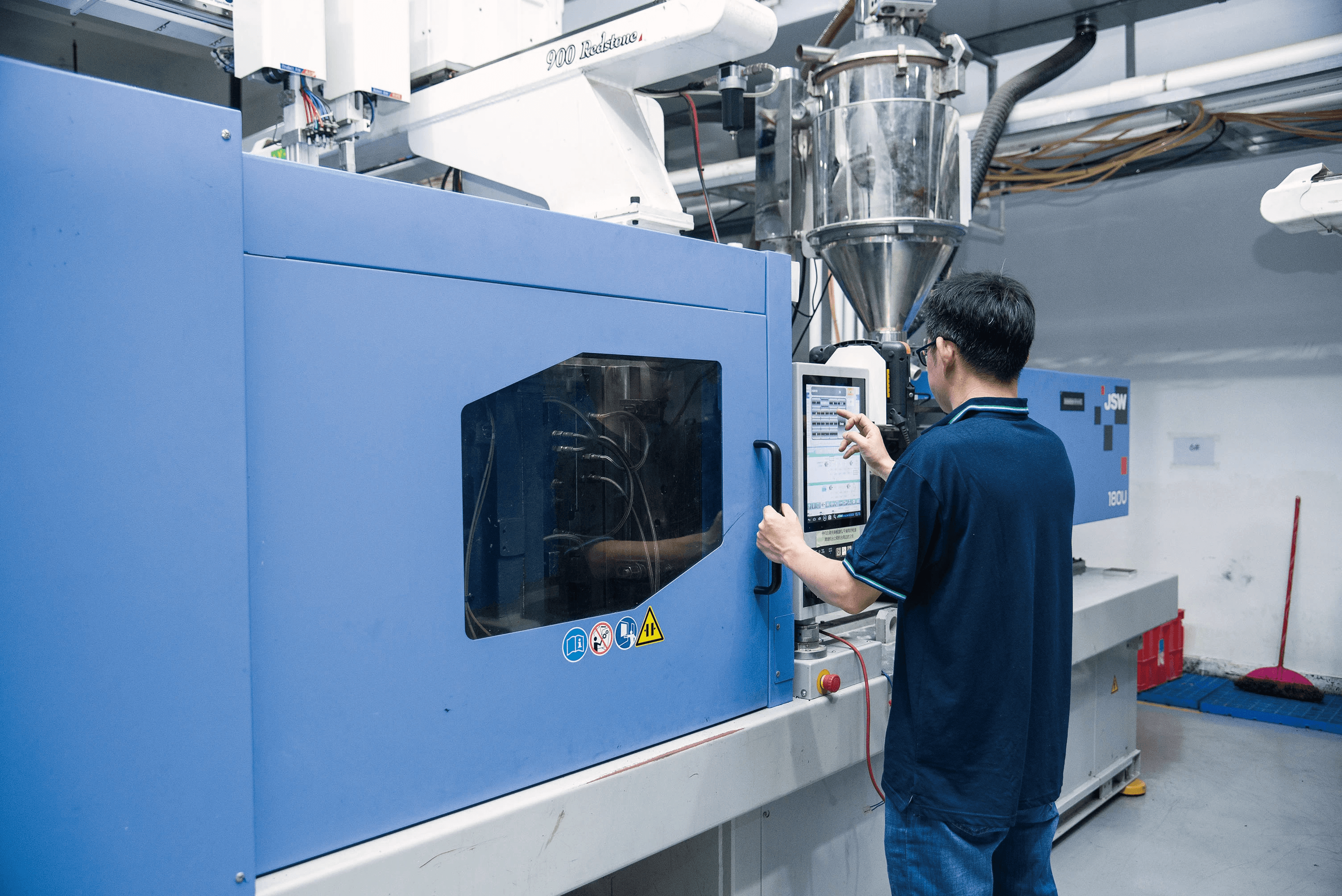

To ensure success in resin injection molding, it's essential to follow best practices during mold plastic injection. First and foremost, maintaining precise temperature control is paramount; it influences the flow characteristics of the resin and ultimately affects the final product's quality. Additionally, ensuring that molds are properly prepared and free from contaminants will help achieve smooth finishes and reduce defects during production.

Another key aspect is selecting appropriate injection speeds based on the viscosity of the resin being used. Faster speeds can improve cycle times but may lead to issues like short shots if not managed carefully. Regular maintenance of equipment also plays a vital role; a well-maintained system minimizes downtime and maximizes efficiency in plastic injection molding processes.

Choosing the Right Mould for Resin Applications

Selecting the right mould for your resin applications is critical in determining both functionality and aesthetics of your final product. The complexity of your design should dictate whether you opt for a simple or multi-cavity mold; intricate designs often require more specialized molds to capture every detail accurately during resin injection molding. Moreover, considering factors such as material compatibility with your chosen resin ensures that there won't be adverse reactions that could compromise structural integrity.

It's also essential to evaluate cooling channels within your molds; efficient cooling systems help reduce cycle times while maintaining uniform temperatures throughout the process. Additionally, choosing high-quality materials for your molds will enhance durability and longevity, ultimately leading to cost savings over time as fewer replacements will be needed due to wear or damage from repeated use in plastic injection molding.

Innovations in Injection Molding Technology

The landscape of injection casting has evolved dramatically thanks to continuous innovations in technology related to resin injection molding. Advanced techniques such as 3D printing are now being integrated into mold-making processes, allowing for rapid prototyping and customization without sacrificing quality or precision in production runs. This synergy between traditional methods and cutting-edge technology enables manufacturers to push boundaries while reducing lead times significantly.

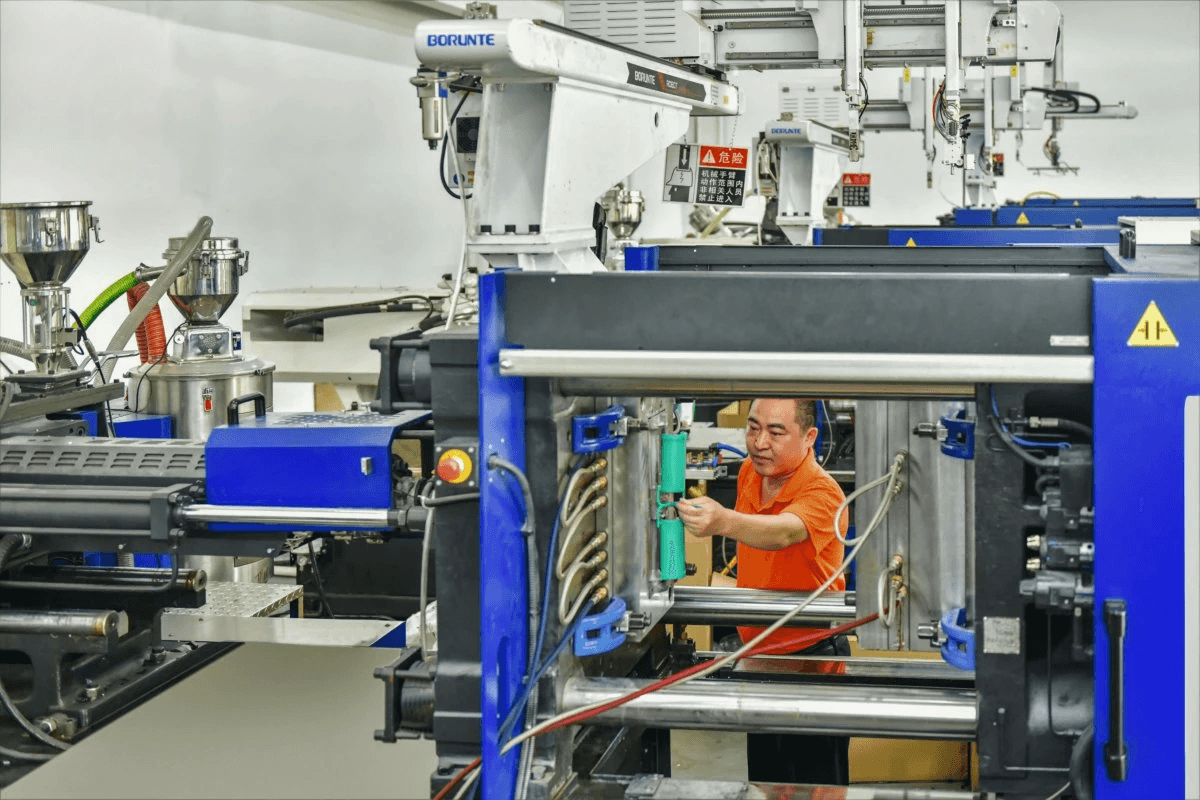

Moreover, automation has become increasingly prevalent within factories utilizing resin and moulds; robotic systems streamline operations by enhancing accuracy while minimizing human error during complex tasks like loading materials or monitoring process parameters closely through real-time data collection systems. These advancements not only improve efficiency but also contribute positively towards sustainability by reducing waste generated throughout production cycles.

As we look ahead into future trends shaping this industry, it’s clear that embracing these innovations will be key for businesses aiming to stay competitive in an ever-evolving market focused on high-quality plastics manufactured through effective techniques like plastic injection molding.

Key Players in the Industry

In the world of resin injection molding, a few key players stand out for their expertise, innovation, and commitment to quality. These companies not only shape the industry but also set the standard for what is possible with resin and moulds. As we delve into this section, we’ll explore Baoyuan's remarkable contributions, highlight leading firms in resin production, and discuss future trends that are poised to redefine injection casting.

Baoyuan's Expertise in Injection Molding

Baoyuan has carved a niche for itself in the realm of injection molding by focusing on high-quality resin products that cater to diverse industries. Their expertise lies in utilizing advanced techniques for mold plastic injection that enhance efficiency and reduce production costs. With a commitment to innovation, Baoyuan continues to develop cutting-edge solutions that address the evolving needs of clients seeking durable and customizable plastic injection molding options.

Moreover, Baoyuan invests heavily in research and development to stay ahead of trends within resin injection molding. This proactive approach allows them to optimize their processes while ensuring that every product meets stringent quality standards. As a result, they have become synonymous with reliability and excellence in the field of resin and moulds.

Leading Companies in Resin Production

The landscape of resin production is dotted with several prominent companies making significant strides in injection molding technology. Industry giants such as BASF, Dow Chemical Company, and Covestro are at the forefront of developing high-performance resins tailored for various applications. These companies not only produce top-notch materials but also collaborate closely with manufacturers to ensure optimal performance during plastic injection molding processes.

In addition to these established names, several innovative startups are emerging on the scene with fresh ideas for sustainable practices within resin injection molding. These newcomers often focus on eco-friendly resins or recycling methods that reduce waste while maintaining product integrity. The competition among these leading firms drives continuous improvement across all aspects of resin production—ensuring customers receive only the best materials available.

Future Trends in Resin and Moulds

Looking ahead, several exciting trends are shaping the future of resin injection molding and its associated technologies. One notable trend is the increasing emphasis on sustainability; manufacturers are exploring bio-based resins that minimize environmental impact without sacrificing performance or durability during mold plastic injection processes. This shift reflects a growing awareness among consumers about eco-friendly products.

Additionally, advancements in 3D printing technology are beginning to merge with traditional techniques used in plastic injection molding molds—creating unique opportunities for customization at unprecedented speeds. The integration of smart manufacturing technologies is also paving new paths toward automation within production lines; this will further enhance efficiency while reducing labor costs associated with manual operations.

As these trends unfold, they promise an exciting evolution within both industries—pushing boundaries further than ever before while ensuring quality remains paramount across all types of injection moldable plastics.

Conclusion

In the ever-evolving world of manufacturing, resin injection molding stands out as a game-changer. This innovative process not only maximizes efficiency but also opens up a plethora of possibilities for designers and engineers alike. As industries increasingly embrace resin and moulds, it’s clear that the future of injection molding is bright and full of potential.

Maximizing Efficiency with Resin Injection Molding

Resin injection molding streamlines production processes by significantly reducing cycle times compared to traditional methods. The rapid curing properties of resin allow for quicker turnarounds, making it an ideal choice for high-volume projects where time is money. Moreover, the precision offered by modern plastic injection molding techniques ensures that each product meets strict quality standards without compromising on speed.

Customization Possibilities in Plastic Injection Molding

One of the most exciting aspects of resin injection molding is its unparalleled customization capabilities. With various formulations available, manufacturers can tailor their resin and moulds to achieve specific characteristics such as flexibility, strength, or color. This level of customization not only enhances product appeal but also allows businesses to meet unique customer demands efficiently.

The Future of Injection Moldable Plastics

Looking ahead, the landscape of injection moldable plastics is set to undergo significant transformations fueled by advancements in technology and materials science. Innovations in resin formulations will likely lead to even more sustainable practices within the industry, addressing environmental concerns while maintaining performance standards. As companies continue to explore new applications for plastic injection molding molds, we can expect a surge in creative designs that push the boundaries of what’s possible with resin.