Introduction

In recent years, the automotive industry has witnessed a remarkable shift towards the use of plastic components, revolutionizing vehicle design and functionality. The rise of automotive plastic components has not only enhanced performance but also contributed to sustainability efforts within the sector. Among these innovations is the bottom plastic part of cars, which plays a crucial role in both protection and efficiency.

The Rise of Automotive Plastic Components

Automakers are increasingly embracing plastics for their versatility and lightweight properties, leading to more fuel-efficient vehicles. This trend has sparked interest in understanding what is the bottom plastic part of the car called and how it fits into this broader movement toward sustainable manufacturing practices. As we explore these automotive plastic components, it becomes clear that they are not just lightweight alternatives but essential elements that enhance overall vehicle performance.

Understanding the Bottom Plastic Part of Cars

So, what is the plastic piece that covers the bottom of a car? Often referred to as an underbody cover or skid plate, this component serves multiple purposes including protecting critical undercarriage parts from debris and improving aerodynamics. By diving deeper into its functionality, we can appreciate how this seemingly simple piece contributes significantly to vehicle longevity and efficiency.

How Plastic Enhances Car Sustainability

The integration of plastics into automotive design promotes sustainability by reducing overall vehicle weight, which in turn lowers fuel consumption and emissions. Additionally, custom plastic injection molding allows manufacturers to create tailored solutions that meet specific needs while minimizing waste during production processes. As we continue to innovate with materials like these, it's clear that plastics will play a pivotal role in shaping a greener future for our roads.

Exploring Automotive Plastic Components

In the modern automotive industry, plastic components have become essential for enhancing vehicle performance and sustainability. From the bottom plastic part of cars to intricate interior fittings, these materials are revolutionizing how vehicles are designed and manufactured. Understanding what automotive plastic components encompass is crucial for grasping their significance in today’s vehicles.

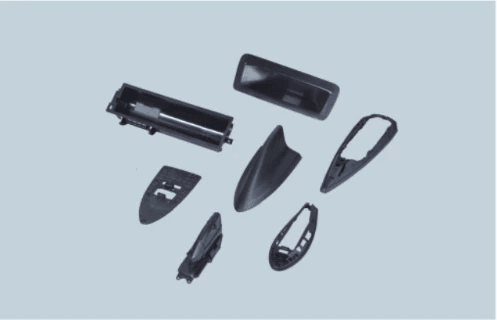

What Are Automotive Plastic Components?

Automotive plastic components refer to the various parts made from synthetic materials that are used throughout a vehicle. These can range from exterior elements like bumpers and panels to interior fixtures such as dashboards and door handles. One notable example is the bottom plastic part of a car, often referred to as an underbody cover or splash shield, which plays a critical role in protecting vital mechanical systems.

Benefits of Using Plastic in Cars

The benefits of using plastics in automotive design are numerous and impactful. For starters, plastics are lightweight compared to traditional materials like metal, which can significantly improve fuel efficiency—a hot topic among eco-conscious drivers. Additionally, plastics offer excellent resistance to corrosion and wear, making them ideal for components like the lower plastic part of the bumper that must endure harsh environmental conditions without degrading over time.

The Role of Custom Plastic Injection Molding

Custom plastic injection molding is a manufacturing process that allows for the precise shaping of complex parts tailored specifically for automotive applications. This technique is vital for producing high-quality automotive plastic components with intricate designs while maintaining consistency across production runs. By utilizing custom molding techniques, manufacturers can create specialized pieces such as what is the lower plastic part of the bumper or what is the plastic piece that covers the bottom of a car with remarkable accuracy and efficiency.

The Bottom Plastic Part of a Car

When you think about the bottom plastic part of a car, it might not be the first thing that comes to mind. Often overshadowed by flashier components, this unsung hero plays a crucial role in automotive design and performance. So, what is the bottom plastic part of the car called? It's commonly referred to as the underbody cover or splash shield, and it's essential for protecting various parts of your vehicle.

What is the Bottom Plastic Part of the Car Called?

The bottom plastic part of a car, known as the underbody cover or splash shield, serves multiple purposes that go far beyond mere aesthetics. This component acts as a protective barrier against debris, moisture, and other environmental factors that could damage vital parts underneath your vehicle. Additionally, it’s often made from lightweight automotive plastic components designed through custom plastic injection molding for durability and efficiency.

Functionality of the Bottom Plastic Part

The functionality of this bottom plastic part is impressive; it not only protects sensitive components like oil pans and exhaust systems but also contributes to aerodynamics and overall vehicle efficiency. By minimizing air resistance beneath the car, this piece helps improve fuel economy—a win-win for both your wallet and the planet! Moreover, its design often includes features that facilitate drainage and prevent water accumulation, further enhancing its protective capabilities.

Environmental Benefits of This Component

The environmental benefits of this component are noteworthy as well; using high-quality automotive plastic components reduces weight without sacrificing strength or durability. A lighter vehicle translates to better fuel efficiency and lower emissions—two critical factors in our quest for sustainability in transportation. Through innovations in custom plastic injection molding techniques, manufacturers are producing these essential pieces with recycled materials whenever possible, making them even more eco-friendly.

The Plastic Piece That Covers the Bottom of a Car

In the automotive world, the plastic piece that covers the bottom of a car is often overlooked but plays a crucial role in vehicle performance. This component, commonly referred to as an underbody cover or skid plate, provides essential protection against road debris and environmental elements. As part of modern automotive plastic components, it showcases how innovation in materials can enhance both functionality and sustainability.

Importance of Underbody Protection

The bottom plastic part of a car is vital for shielding critical components from damage caused by rocks, dirt, and other road hazards. Without this protective layer, parts like the oil pan and transmission could suffer costly damage during everyday driving scenarios. Moreover, it helps prevent corrosion by acting as a barrier against moisture and grime that can accumulate on exposed surfaces.

How This Plastic Piece Affects Fuel Efficiency

Interestingly, the bottom plastic part of a car also plays an unexpected role in fuel efficiency. By streamlining airflow beneath the vehicle, this plastic piece reduces drag while driving at high speeds. Less aerodynamic drag means that engines don’t have to work as hard to maintain speed, ultimately leading to better fuel economy—a win-win for both drivers and the environment.

Innovations in Underbody Design

Recent advancements in custom plastic injection molding have led to innovative designs for these underbody covers that are lighter yet stronger than ever before. Manufacturers are now using advanced composites that not only enhance durability but also contribute to overall vehicle weight reduction. These innovations ensure that what is often considered just the plastic piece that covers the bottom of a car becomes an integral element in enhancing both performance and sustainability.

Understanding the Lower Plastic Part of the Bumper

When it comes to automotive design, every component plays a crucial role, and the lower plastic part of the bumper is no exception. This essential piece, often overlooked, serves multiple functions while enhancing both aesthetics and functionality. So, what is the lower plastic part of the bumper? It’s not just a decorative element; it’s a vital component that contributes to vehicle performance and safety.

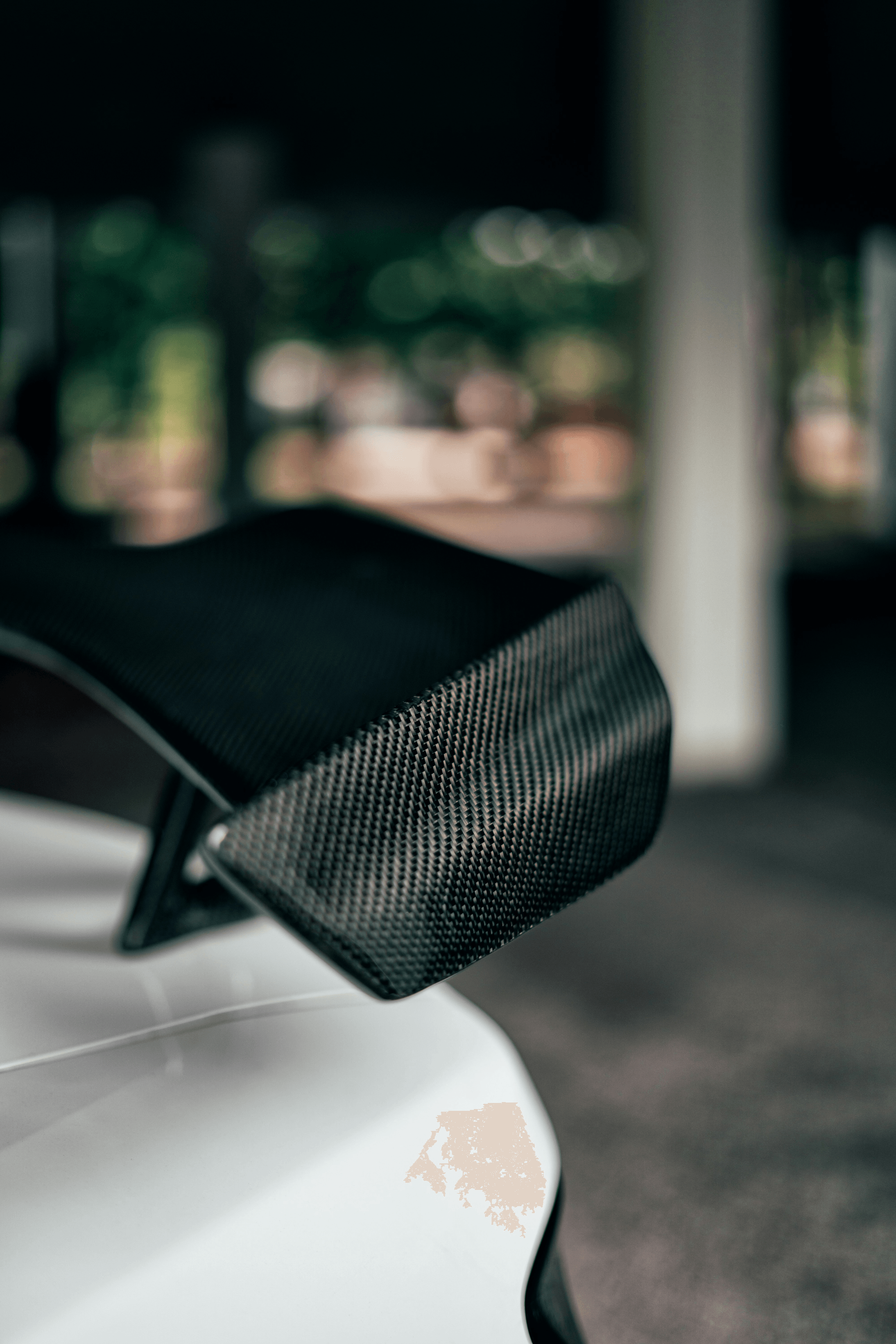

Function and Design of the Lower Bumper Plastic

The lower plastic part of the bumper is designed primarily for protection and aerodynamics. It acts as a shield against minor impacts and debris that can damage more critical components of your vehicle. Additionally, its design helps streamline airflow around the car, improving fuel efficiency—a feature that aligns perfectly with modern sustainability goals.

In terms of aesthetics, this plastic piece can be molded into various shapes and colors through custom plastic injection molding techniques. This flexibility allows manufacturers to create visually appealing designs that match different car models while maintaining functionality. With advancements in automotive plastic components, these lower bumper parts are now more durable than ever.

Impact on Vehicle Safety

Safety is paramount in automotive design, and the lower plastic part of the bumper plays a significant role in protecting passengers during collisions. This component absorbs impact energy during low-speed accidents, reducing damage to more expensive parts like radiators and frames—essentially acting as a buffer zone for your vehicle's integrity.

Moreover, effective design ensures that these pieces do not compromise pedestrian safety standards; they are crafted to minimize injury risk during unfortunate encounters with pedestrians or cyclists. With rigorous testing standards in place for automotive plastic components like these bumpers, you can drive with confidence knowing that safety has been prioritized.

Durable Materials for Enhanced Longevity

Durability is key when discussing what is called the lower plastic part of the bumper because it faces harsh conditions daily—from road debris to extreme weather changes. Manufacturers utilize high-quality materials such as polypropylene or thermoplastic elastomers (TPE), which offer excellent resistance to impact and environmental stressors while being lightweight enough not to hinder performance.

These materials not only enhance longevity but also contribute to overall vehicle sustainability by ensuring fewer replacements over time—reducing waste generated from frequent repairs or replacements. The use of custom plastic injection molding allows for precise engineering in creating these durable parts tailored specifically for each vehicle model's needs.

The Role of Baoyuan in Sustainable Manufacturing

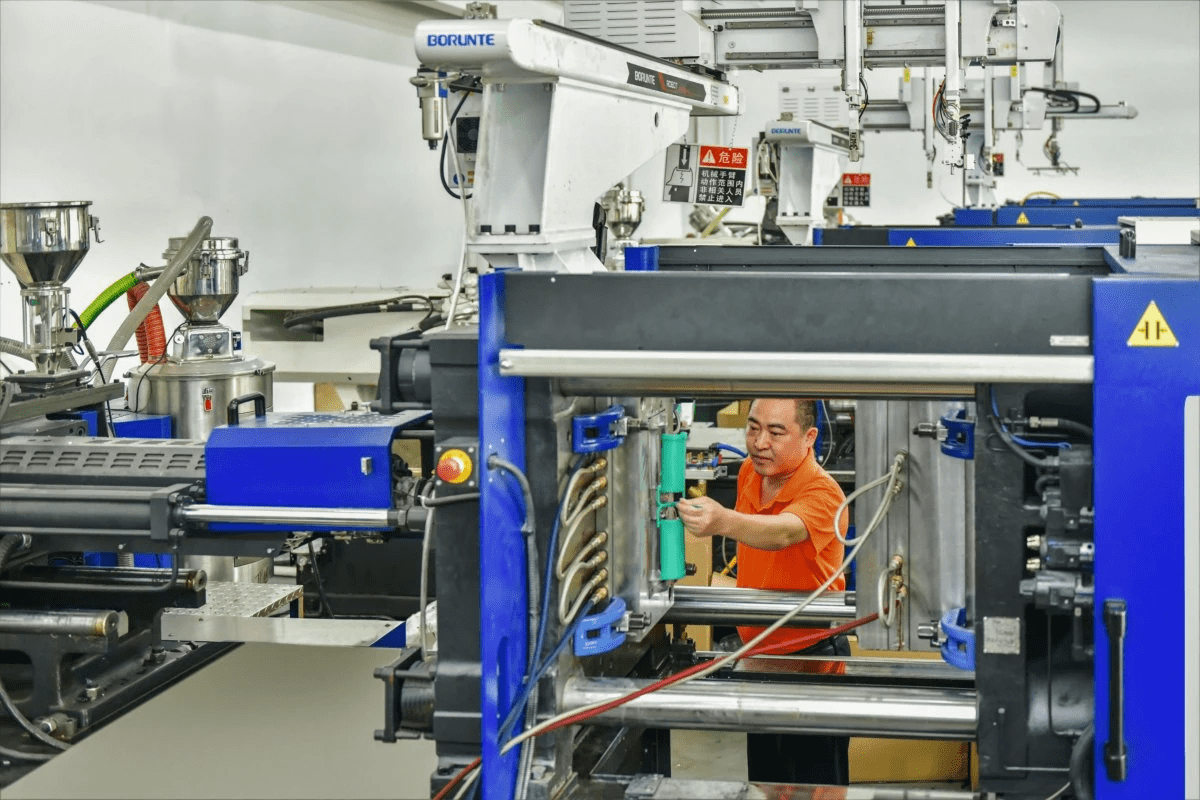

Baoyuan has established itself as a key player in the realm of sustainable manufacturing, particularly through its innovative approach to custom plastic injection molding. This process allows for the precise creation of automotive plastic components, including the bottom plastic part of a car and various other essential pieces. By focusing on customization, Baoyuan ensures that each component meets specific vehicle requirements while minimizing waste and maximizing efficiency.

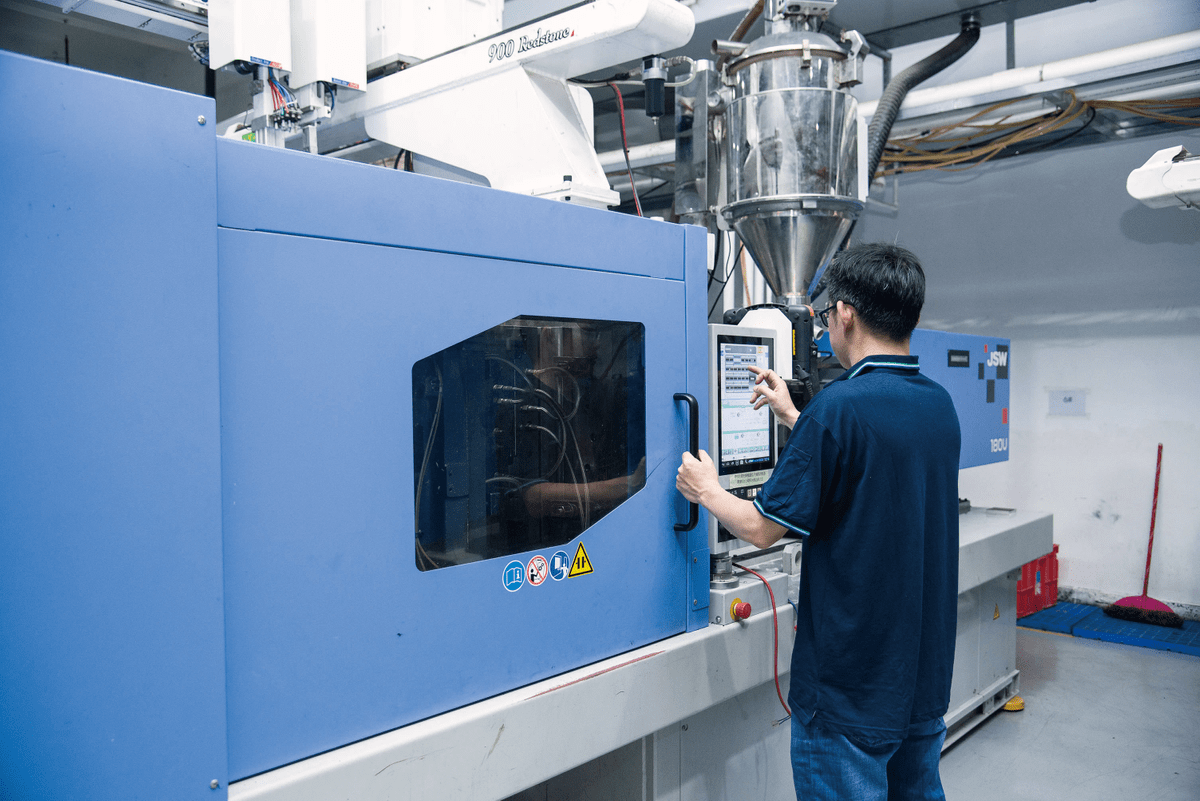

Baoyuan's Expertise in Custom Plastic Injection Molding

When it comes to understanding what is the bottom plastic part of the car called, Baoyuan’s expertise shines through in its ability to produce high-quality components tailored for diverse automotive applications. Their custom plastic injection molding techniques enable them to craft everything from underbody shields to lower bumper parts with exceptional precision. This level of specialization not only enhances vehicle performance but also contributes to sustainability by reducing excess material usage.

Baoyuan’s commitment to innovation means they are continually refining their processes and materials used in creating automotive plastic components. By investing in advanced technologies and training, they ensure that their production methods are both efficient and environmentally friendly. As a result, customers can trust that when they ask what is the plastic piece that covers the bottom of a car, it will be manufactured with care for both quality and sustainability.

Quality Assurance in Automotive Plastic Production

Quality assurance is at the heart of Baoyuan's manufacturing philosophy, especially when producing critical automotive parts like the lower plastic part of the bumper or other protective components. Rigorous testing protocols ensure that every piece meets strict safety standards while maintaining durability over time. This focus on quality not only protects consumers but also reinforces trust in Baoyuan’s products across the automotive industry.

Moreover, Baoyuan employs advanced monitoring systems throughout their production lines which allow for real-time adjustments during manufacturing processes. This proactive approach helps maintain consistency across all automotive plastic components produced at their facilities. When considering what is the lower plastic part of the bumper or any other component, customers can rest assured knowing it has undergone meticulous quality checks before reaching them.

Innovations by Baoyuan in Eco-friendly Practices

In an era where sustainability is paramount, Baoyuan leads by example with its eco-friendly practices integrated into every step of production. From sourcing recycled materials for custom plastic injection molding to implementing energy-efficient machinery, they strive to reduce their carbon footprint significantly. These innovations reflect a broader commitment not just toward making high-quality products like those covering the bottom of cars but also toward preserving our planet.

Additionally, Baoyuan actively engages in research and development aimed at improving material recyclability within automotive applications—an important factor given increasing environmental concerns surrounding plastics today. Their efforts align perfectly with growing consumer demand for greener alternatives without sacrificing performance or safety features found within automotive designs like those involving lower bumper plastics or underbody shields.

By continuously pushing boundaries regarding eco-friendly practices and product development while answering questions such as what is the bottom plastic part of a car called?—Baoyuan positions itself as a leader advocating for sustainable solutions within the industry.

Conclusion

As we wrap up our exploration of automotive plastic components, it’s clear that embracing plastics is not just a trend but a crucial step toward a greener future. The bottom plastic part of the car, often overlooked, plays a vital role in enhancing sustainability while providing essential protection and efficiency. By utilizing custom plastic injection molding techniques, manufacturers can create parts that are both lightweight and durable, significantly reducing the environmental impact of vehicles.

Embracing Plastics for a Greener Future

The rise of automotive plastic components highlights an innovative approach to vehicle design that prioritizes sustainability without sacrificing performance. The bottom plastic part of the car is not only functional but also contributes to lower emissions by reducing overall vehicle weight. As we move forward, it's essential for manufacturers and consumers alike to recognize the potential of these materials in creating eco-friendly automobiles.

The Impact of Plastic on Automotive Design

Plastic has revolutionized automotive design by allowing for greater flexibility and creativity in form and function. For instance, what is the bottom plastic part of the car called? It's often referred to as an underbody cover or splash shield, which provides protective benefits while enhancing aerodynamics. Additionally, innovations in how we design the lower plastic part of the bumper have resulted in safer vehicles that meet rigorous safety standards while still being lightweight.

How You Can Advocate for Sustainable Practices

Advocating for sustainable practices starts with awareness—understanding what is the plastic piece that covers the bottom of a car and its significance can spark important conversations about vehicle design and production methods. Encourage automakers to continue investing in custom plastic injection molding technologies that prioritize recycling and resource conservation. By supporting companies committed to using automotive plastic components responsibly, you contribute to a more sustainable future for all.