Introduction

The world of manufacturing is a complex tapestry woven with various processes, and one of the most vital threads in this fabric is the injection molding process. This technique serves as a cornerstone for producing high-quality plastic products, revolutionizing how industries create components and finished goods. Understanding the intricacies of injection molding not only highlights its importance but also showcases its transformative impact on modern manufacturing.

Understanding the Injection Molding Process

At its core, the injection molding process involves injecting molten plastic into a mold to create precise shapes and designs. This method utilizes injection moldable plastics that can be easily shaped and solidified to form intricate parts, making it an ideal choice for mass production. The efficiency of this process allows manufacturers to produce large quantities of consistent products while minimizing waste and reducing lead times.

Why Injection Molding Matters for Manufacturing

Injection molding matters significantly in manufacturing due to its ability to streamline production while maintaining high quality. As industries strive for efficiency, plastic injection molding emerges as a go-to solution, enabling companies to meet market demands swiftly without sacrificing product integrity. Moreover, the versatility inherent in mold plastic injection means that manufacturers can adapt quickly to changing needs or specifications, ensuring they stay competitive in an ever-evolving marketplace.

Key Benefits of Custom Plastic Injection Molding

Custom plastic injection molding offers several key benefits that make it an attractive option for businesses looking to optimize their production processes. One major advantage is the ability to design molds tailored specifically for unique applications, resulting in products that meet exact specifications and performance requirements. Additionally, custom solutions often lead to cost savings by minimizing material waste and maximizing production efficiency—an essential factor for any manufacturer aiming for profitability.

What is Injection Molding?

Injection molding is a manufacturing process that transforms raw plastic materials into finished products through a series of precise steps. This method involves injecting molten plastic into a mold, where it cools and solidifies into the desired shape. Understanding the injection molding process is crucial for anyone looking to create high-quality plastic products efficiently.

Definition and Basic Concepts

At its core, injection molding is all about efficiency and precision. The process begins with heating thermoplastic or thermosetting polymers until they become pliable enough to be injected into a mold. Once injected, the material cools and hardens, creating intricate shapes that can be replicated with remarkable accuracy in subsequent cycles.

The basic concepts include understanding how different types of injection moldable plastics behave under heat and pressure, as well as the role of temperature control during the cooling phase. Key components such as the injection unit, clamping unit, and mold design are critical for ensuring that the final product meets strict quality standards. In essence, mastering these concepts lays the groundwork for successful custom plastic injection molding.

The Role of Injection Moldable Plastics

Injection moldable plastics are at the heart of this manufacturing technique; without them, there would be no molded parts to speak of! These materials come in various types—each with unique properties suitable for different applications—from rigid polystyrene to flexible thermoplastic elastomers. Selecting the right type of injection moldable plastics not only affects product performance but also influences production costs and timelines.

Moreover, advancements in polymer science have led to innovative materials that enhance durability and functionality while maintaining ease of processing during the injection molding process. Whether it’s developing lightweight automotive components or complex medical devices, choosing high-quality plastics ensures that end products meet industry standards while offering longevity and reliability. Thus, understanding these materials is essential for anyone involved in plastic injection molding.

Overview of Plastic Injection Molding Techniques

There’s more than one way to skin a cat—or in this case—produce plastic products! Various techniques exist within the realm of plastic injection molding that cater to specific needs and applications. From traditional methods like two-shot or multi-material molding to advanced techniques such as gas-assisted or insert molding, each approach offers unique advantages depending on project requirements.

For instance, two-shot molding allows manufacturers to combine different colors or materials in one seamless product while maintaining structural integrity—a game-changer for custom plastic injection molding projects requiring aesthetic appeal alongside functionality. Gas-assisted techniques can reduce cycle times by optimizing material flow during cooling phases; this not only expedites production but also minimizes waste—a win-win scenario! Understanding these diverse techniques empowers manufacturers to choose methods best suited for their specific goals within the broader framework of the injection molding process.

The Injection Molding Process Breakdown

The injection molding process is a sophisticated yet fascinating method that allows manufacturers to create intricate plastic products with precision and efficiency. Understanding this process is crucial for anyone involved in the production of custom plastic injection molding items. By breaking down the steps, we can appreciate how each component contributes to the final product's quality and functionality.

Step-by-Step Overview of the Process

The injection molding process begins with the preparation of raw materials, specifically injection moldable plastics, which are often in pellet form. These pellets are then heated until they melt, forming a viscous liquid that can be injected into a mold plastic injection cavity under high pressure. Once injected, the material cools and solidifies within the mold, resulting in a finished plastic product that can be ejected and further processed if necessary.

This step-by-step approach ensures that every phase of production is meticulously executed for optimal results. From heating and injecting to cooling and ejection, each action plays a vital role in determining the quality and precision of the final piece. Additionally, understanding these steps helps manufacturers troubleshoot any issues that may arise during production.

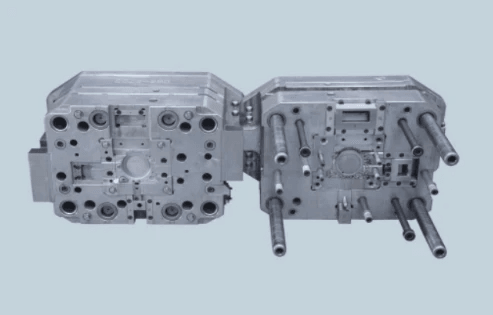

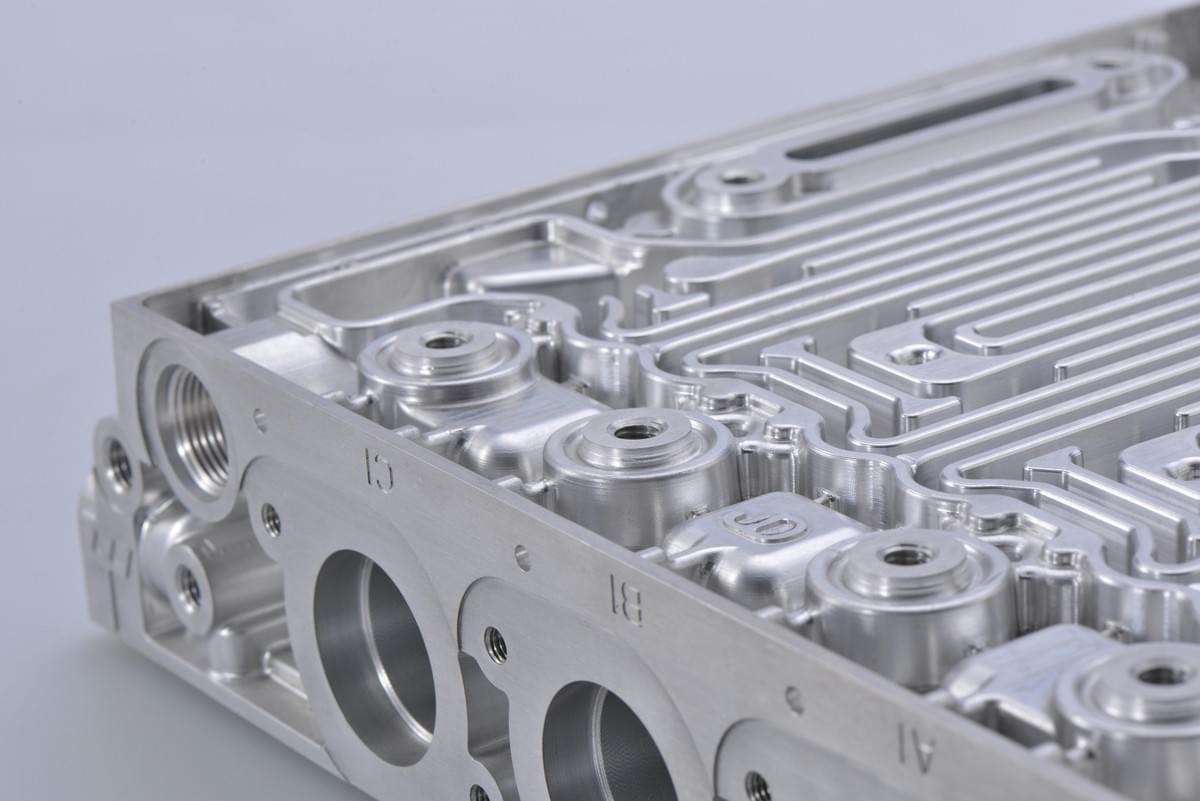

Importance of the Injection Mold Plastic Design

The design of the injection mold plastic is paramount in ensuring successful outcomes during manufacturing. A well-designed mold not only facilitates efficient filling but also minimizes defects such as warping or incomplete filling—issues that can plague even seasoned manufacturers if not addressed correctly. Moreover, effective mold design allows for better control over cooling times and cycle rates, significantly impacting production efficiency.

Investing time in designing an optimal plastic injection molding mold pays dividends by reducing waste and enhancing product quality. Customization options abound; from intricate geometries to specific surface finishes, thoughtful design translates directly into superior products tailored to meet market demands. Ultimately, when companies prioritize good design practices for their molds, they set themselves up for success in producing high-quality plastic products.

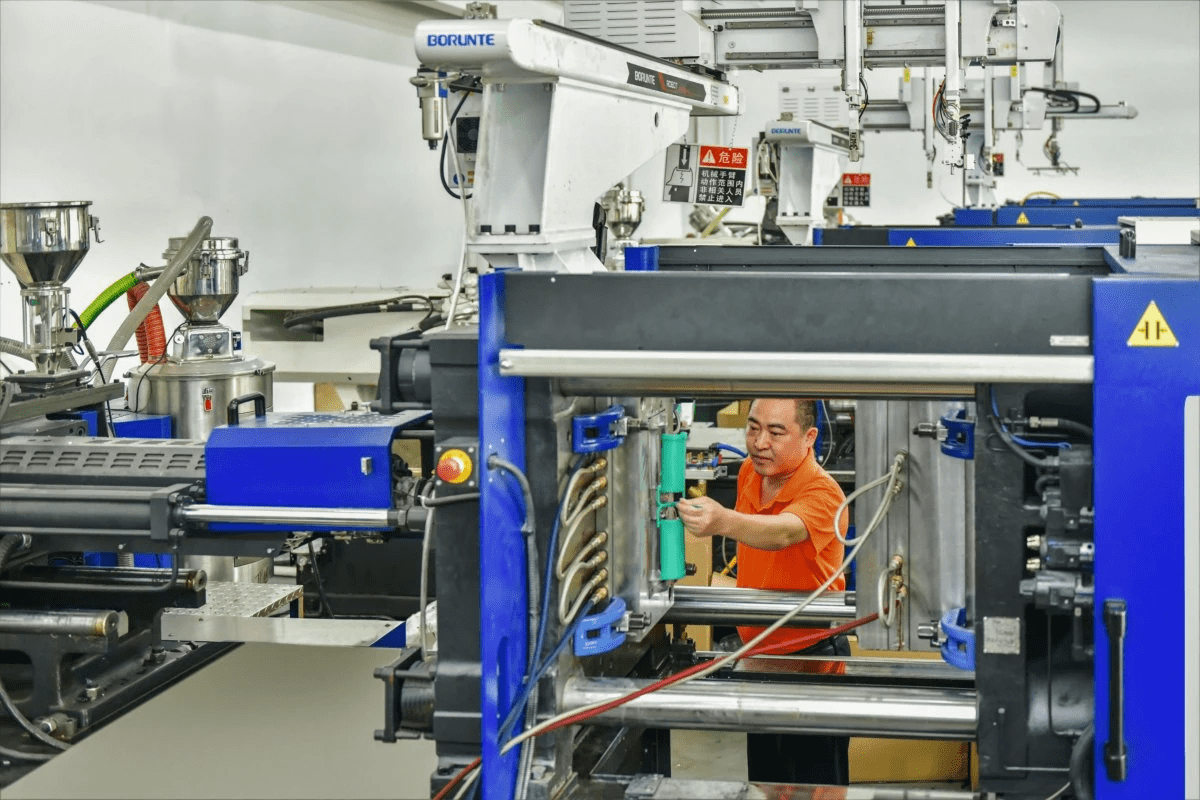

Common Machinery Used in Injection Molding

Several types of machinery are integral to executing an efficient injection molding process effectively. The primary machine used is known as an injection molding machine (IMM), which consists of two main parts: the injector assembly where melted plastics are injected into molds and the clamping unit that holds molds together under pressure during production cycles.

Additionally, auxiliary equipment such as temperature controllers help maintain optimal conditions throughout processing while robots may assist with automated part removal or finishing processes after ejection from molds. Understanding this machinery helps businesses make informed decisions about their equipment choices based on their specific needs within custom plastic injection molding projects.

Advantages of Using Injection Molding

The injection molding process has revolutionized the way plastic products are manufactured, offering a range of advantages that make it a go-to technique for many industries. From cost savings to high precision, the benefits of injection molding are numerous and impactful. Understanding these advantages can help businesses make informed decisions about their manufacturing processes.

Cost-Effectiveness for Mass Production

One of the standout features of the injection molding process is its remarkable cost-effectiveness, especially when it comes to mass production. Once the initial setup costs for creating a mold plastic injection are covered, producing each additional unit becomes significantly cheaper. This efficiency allows manufacturers to lower their per-unit costs while maintaining high output levels, making custom plastic injection molding an attractive option for large-scale production.

Moreover, the automation involved in plastic injection molding reduces labor costs and minimizes human error during production runs. This means that businesses can focus on scaling their operations without worrying about skyrocketing expenses associated with manual labor or inefficient processes. In essence, investing in injection moldable plastics pays off handsomely when producing thousands or even millions of identical parts.

High Precision and Quality of Plastic Products

Another compelling advantage of injection molding lies in its ability to produce high-precision and quality plastic products consistently. The precision offered by modern machines ensures that each part meets stringent specifications, which is essential for industries where tolerances are critical. Whether it's automotive components or medical devices, using a well-designed plastic injection molding mold guarantees that every item produced is uniform and reliable.

Additionally, the materials used in the injection molding process contribute significantly to product quality. With various types of injection moldable plastics available—ranging from flexible to rigid—manufacturers can select materials that best suit their specific needs without compromising on strength or durability. This versatility allows businesses to create products that not only look good but also perform exceptionally well over time.

Versatility of Materials and Uses

The versatility inherent in custom plastic injection molding cannot be overstated; it opens doors to endless possibilities across different sectors. Manufacturers can utilize an array of materials—such as thermoplastics and thermosetting plastics—to create anything from simple household items to complex industrial components with intricate designs. This adaptability makes it easier for businesses to pivot according to market demands while still delivering top-notch products.

Furthermore, innovations within the realm of mold design have allowed manufacturers to explore new shapes and functionalities previously thought impossible with traditional methods. The ability to integrate multiple functions into one molded part reduces assembly times and overall production complexity—a win-win situation! As industries evolve and consumer preferences shift toward more sustainable options, the flexibility offered by modern plastic injection molding techniques positions companies favorably for future growth.

Common Applications for Injection Molding

The injection molding process is a cornerstone of modern manufacturing, impacting various industries by enabling the efficient production of a wide range of plastic products. From automotive components to consumer electronics, the versatility of injection moldable plastics allows for innovative designs and functionalities. As businesses continue to seek cost-effective solutions, custom plastic injection molding has emerged as a preferred method for producing high-quality items tailored to specific needs.

Industries Relying on Plastic Injection Molding

Numerous industries depend heavily on the injection molding process to meet their production demands and maintain competitive advantages. The automotive industry, for example, utilizes plastic injection molding extensively for creating lightweight yet durable parts that enhance vehicle performance and fuel efficiency. Similarly, the healthcare sector relies on precision-engineered plastic products such as syringes and surgical instruments made through advanced plastic injection molding techniques.

Consumer goods manufacturers also harness the power of mold plastic injection to create everything from household items to packaging solutions that are both functional and aesthetically pleasing. The electronics industry benefits from this process by producing intricate components that require high precision while ensuring quality standards are met. With such diverse applications across these sectors, it's clear that custom plastic injection molding plays a pivotal role in driving innovation and efficiency in manufacturing.

Examples of Products Made with Injection Molding

The range of products produced through the injection molding process is astonishingly broad, showcasing its adaptability across different markets. Everyday items like bottle caps, containers, and toys often originate from this technique due to its ability to produce large quantities quickly without sacrificing quality. Additionally, complex components like connectors or casings for electronic devices demonstrate how far-reaching the applications of injection moldable plastics can be.

In industries like aerospace and defense, specialized parts such as housings or brackets are crafted using precise molds designed specifically for high-stakes environments where reliability is paramount. Even in construction, custom plastic injection molding yields essential elements like piping systems or insulation materials that contribute significantly to building safety and efficiency. These examples illustrate how integral the plastic injection molding process is in delivering functional solutions across various domains.

Innovations in Custom Plastic Injection Molding

Innovation within custom plastic injection molding continues at an impressive pace as manufacturers seek new ways to enhance product performance and sustainability. Advanced technologies such as 3D printing integration with traditional mold making are revolutionizing how prototypes are developed—allowing faster iterations and more creative designs without incurring significant costs upfront. This fusion not only speeds up production times but also enables designers to experiment with complex geometries previously deemed impractical.

Moreover, eco-friendly initiatives have led many companies toward utilizing biodegradable materials in their mold plastic injections—reducing waste while maintaining product integrity over time. Smart manufacturing practices incorporating IoT (Internet of Things) technologies into machinery help monitor processes closely, ensuring optimal output quality throughout production cycles while minimizing downtime associated with machinery malfunctions or inefficiencies. These innovations reflect an exciting future for the injection molding process as it adapts to meet modern challenges head-on.

Challenges in the Injection Molding Process

The injection molding process, while efficient and versatile, is not without its challenges. From mold design intricacies to production hiccups, understanding these potential issues can save time and resources. A well-executed custom plastic injection molding project requires an awareness of these challenges to ensure high-quality plastic products.

Potential Issues with Mold Design and Production

Mold design is a critical factor in the success of the injection molding process. Poorly designed molds can lead to defects in the final product, such as warping or inconsistent thickness. Additionally, issues during production—like improper cooling or material flow—can exacerbate problems, resulting in wasted materials and increased costs for manufacturers.

Another common challenge arises from selecting the wrong injection moldable plastics for specific applications. Each type of plastic has unique properties that affect how it behaves during the injection molding process. Therefore, understanding these materials is crucial for avoiding costly mistakes that can derail production timelines.

Moreover, maintaining precision during both mold creation and production is essential to achieving high-quality outcomes. Any misalignment or error in measurements can lead to significant setbacks in producing reliable plastic products. Thus, investing time in thorough planning and testing at this stage pays off when it comes to delivering top-notch results.

Quality Control and Assurance Practices

Quality control is paramount throughout every step of the plastic injection molding process. Implementing robust quality assurance practices ensures that each batch meets stringent standards before reaching customers’ hands. Regular inspections during production help identify defects early on, preventing costly recalls or reworks down the line.

Incorporating advanced technologies like automated inspection systems enhances quality control efforts significantly. These systems provide real-time feedback on product specifications and help maintain consistency across large volumes of molded parts. By leveraging such innovations, manufacturers can uphold their reputation for producing exceptional plastic products.

Furthermore, establishing clear protocols for testing molded items post-production is vital for maintaining quality assurance standards within custom plastic injection molding projects. This includes stress tests or dimensional checks that confirm whether a product meets required specifications before leaving the facility. Consistent adherence to these practices fosters trust between manufacturers and their clients while minimizing risks associated with faulty products.

The Importance of Expertise like Baoyuan’s Team

Navigating the complexities of the injection molding process requires a skilled team with extensive knowledge about various aspects of manufacturing techniques and material science. This expertise becomes even more critical when dealing with custom projects that demand tailored solutions specific to client needs or industry standards.

Baoyuan’s team exemplifies this level of expertise by providing comprehensive support throughout all stages—from initial design consultations through mold creation and final production runs using advanced machinery suited for diverse applications within plastic injection molding molds. Their experience helps clients avoid common pitfalls associated with poor design choices or inadequate material selection.

Ultimately, partnering with a knowledgeable team ensures successful project execution while mitigating risks inherent in complex manufacturing processes like those found in custom plastic injection molding endeavors—leading to superior quality outcomes that stand out in today’s competitive market landscape.

Conclusion

In wrapping up our exploration of the injection molding process, it's clear that mastering this technique is essential for anyone looking to thrive in the manufacturing landscape. The intricacies of custom plastic injection molding not only highlight its importance but also emphasize the need for precision and quality in creating plastic products. As industries continue to evolve, understanding these processes will be crucial for maintaining a competitive edge.

Mastering the Injection Molding Process

To truly master the injection molding process, one must delve into every aspect—from mold design to material selection and production techniques. A well-designed plastic injection molding mold can significantly enhance efficiency and product quality, ensuring that each batch meets rigorous standards. Moreover, continuous education on advancements in injection moldable plastics can further refine your approach, allowing you to produce innovative and high-quality plastic products.

Future Trends in Plastic Injection Molding

The future of plastic injection molding is poised for exciting developments as technology advances and sustainability becomes a priority. Innovations such as 3D printing integration with traditional methods are paving new avenues for custom plastic injection molding applications, enhancing both speed and flexibility. Additionally, an increased focus on eco-friendly materials will reshape how we view mold plastic injection processes, leading to greener practices that benefit both manufacturers and consumers.

Finding the Right Partner for Injection Molding Success

Choosing the right partner for your injection molding needs can be a game changer in achieving success with your projects. Look for companies that not only have expertise in the injection molding process but also demonstrate a commitment to quality control and customer satisfaction. With partners like Baoyuan’s team who understand the nuances of producing top-notch plastic products through effective collaboration and innovation, you’ll be well on your way to achieving remarkable results.