Introduction

In the world of manufacturing, prototype injection molding stands out as a crucial process for creating precise and efficient prototypes. This technique involves using injection molding to produce plastic parts that are both functional and cost-effective, allowing designers and engineers to validate their concepts before full-scale production. With its ability to create complex geometries and intricate designs, prototype plastic injection molding has revolutionized the way products are developed across various industries.

What is Prototype Injection Molding?

Prototype injection molding is a specialized form of injection molding that focuses on producing prototypes rather than final production runs. It employs the same basic principles of injecting molten plastic into a mold, but with an emphasis on speed and flexibility in design iterations. This method allows for rapid testing of product designs, enabling teams to identify potential issues early in the development process.

Importance of Prototype Injection Molding

The significance of prototype injection molding cannot be overstated; it serves as a bridge between concept and reality in product development. By utilizing this method, companies can save time and resources while ensuring that their designs meet functional requirements before committing to mass production. Furthermore, it fosters innovation by allowing designers to experiment with different shapes, sizes, and materials without incurring substantial costs.

Choosing the Right Materials

Selecting appropriate materials for prototype plastic injection molding is essential for achieving desired performance characteristics in final products. Factors such as strength, flexibility, temperature resistance, and appearance play critical roles in determining which injection moldable plastics will best suit specific applications. By understanding material properties and how they interact with the mold plastic injection process, engineers can make informed decisions that enhance both functionality and aesthetics in their prototypes.

Understanding the Basics of Injection Molding

Injection molding is a fascinating process that has revolutionized the production of plastic components across various industries. With its ability to create complex shapes and high-volume outputs, it’s no wonder that prototype injection molding has gained traction among manufacturers and designers alike. In this section, we’ll delve into how injection molding works, explore the advantages of prototype injection molding, and identify common applications in industries that benefit from this technology.

How Injection Molding Works

At its core, injection molding is a manufacturing process where molten plastic is injected into a mold to create parts or products. The process begins with heating plastic pellets until they melt into a viscous liquid, which is then injected under high pressure into a pre-designed mold plastic injection cavity. Once cooled and solidified, the mold opens to release the finished product—voilà! This method allows for precision in creating intricate designs with minimal waste.

The beauty of plastic injection molding lies in its efficiency; it can produce thousands of identical parts quickly and consistently. As such, it’s particularly suited for mass production runs where time and cost savings are critical factors. With advancements in technology, prototype plastic injection molding can also be adapted for smaller batches without sacrificing quality or speed.

Advantages of Prototype Injection Molding

Prototype injection molding offers several advantages that make it an appealing choice for designers looking to bring their ideas to life. One major benefit is the ability to test designs before committing to full-scale production; this not only saves time but also significantly reduces costs associated with design flaws or material waste. By creating prototypes using injection moldable plastics, engineers can evaluate functionality and aesthetics while making necessary adjustments early in the development phase.

Another advantage lies in the versatility of materials available for use in prototype injection molding. From standard thermoplastics like ABS and polycarbonate to specialized engineering plastics, there’s a wide range of options tailored for specific applications and performance requirements. This flexibility ensures that manufacturers can choose materials best suited for their intended use without compromising quality or durability.

Finally, the speed at which prototypes can be produced using this method cannot be overstated—what once took weeks or months can now often be achieved in days! This rapid turnaround allows companies to stay competitive by quickly iterating on designs based on feedback from stakeholders or end-users.

Common Applications in Industries

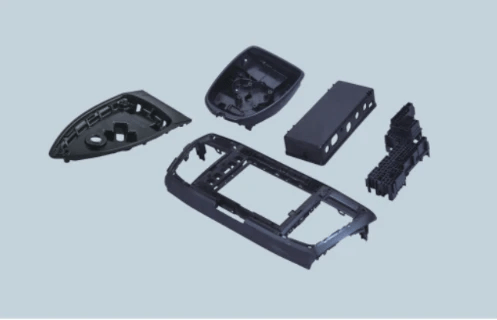

Prototype injection molding finds applications across numerous industries due to its adaptability and efficiency in producing high-quality components. The automotive sector frequently relies on this technology for creating everything from interior panels to complex engine parts made from durable plastics designed to withstand harsh conditions. By utilizing prototype plastic injection molding techniques during development stages, automakers can ensure their products meet safety standards while optimizing performance.

In addition to automotive applications, consumer electronics heavily depend on precision-molded components produced through plastic injection molding processes. Items such as mobile phone casings, connectors, and housing units benefit from both aesthetic appeal and structural integrity achieved via customized molds tailored specifically for each product line's needs—making them essential elements within modern devices we use daily.

Healthcare is yet another industry leveraging prototype injection molding effectively; medical devices often require intricate designs combined with biocompatible materials suitable for patient safety during usage or implantation procedures. By employing advanced manufacturing techniques like these early on during R&D phases ensures compliance with regulatory standards while accelerating time-to-market timelines—a win-win situation!

Selecting Injection Moldable Plastics

Choosing the right materials for prototype injection molding is crucial for achieving optimal results. The selection of injection moldable plastics can significantly impact the performance, durability, and cost-effectiveness of your final product. Understanding the various types of plastics available and the factors influencing your choice will empower you to make informed decisions in plastic injection molding.

Types of Injection Moldable Plastics

When it comes to prototype plastic injection molding, there are several types of injection moldable plastics to consider. Thermoplastics, such as ABS, polycarbonate, and polypropylene, are popular choices due to their versatility and ease of processing. On the other hand, thermosetting plastics like epoxy resins provide excellent heat resistance and stability but are less flexible during manufacturing.

Another category worth mentioning is elastomers, which offer rubber-like properties ideal for applications requiring flexibility and resilience. Each type has its unique characteristics that make it suitable for specific applications within plastic molding industries. By understanding these options, you can better align your material choice with your project requirements in prototype injection molding.

Factors to Consider When Choosing Materials

Selecting the right material goes beyond just knowing what types are available; it's about evaluating various critical factors that influence performance in plastic injection molding. First off, consider mechanical properties such as strength, flexibility, and impact resistance—these will determine how well your part performs under stress or strain during its lifecycle.

Next up is thermal stability; if your application involves exposure to high temperatures or fluctuating environments, you'll want a material that can withstand those conditions without warping or degrading over time. Lastly, don’t forget about cost-effectiveness; while some advanced materials may offer superior properties for prototype plastic injection molding projects, they might also come with a hefty price tag that could affect your budget.

Designing Effective Molds

Designing effective molds is crucial for the success of prototype injection molding projects. A well-designed mold not only ensures precision and quality in the final product but also optimizes production efficiency. Understanding the intricacies of mold design can significantly enhance the overall performance of plastic injection molding processes.

Key Principles in Mold Design

When diving into the world of mold design, several key principles should be kept in mind. First, consider the flow of molten plastic; ensuring that it reaches all areas of the mold evenly is essential for a uniform product. Additionally, incorporating features like draft angles and proper venting can facilitate easier part removal and prevent air entrapment during injection molding.

Another critical principle is to account for thermal expansion and contraction during cooling cycles in plastic injection molding. Choosing appropriate materials that withstand heat while maintaining structural integrity is vital for achieving durable molds. Lastly, ease of maintenance should never be overlooked—designing molds that allow for quick repairs or adjustments can save time and costs down the line.

Importance of Mold Plastic Injection Precision

Precision in mold plastic injection is non-negotiable when it comes to producing high-quality prototypes or final products. Any inconsistencies in mold dimensions can lead to defects such as warping or misalignment, ultimately compromising product functionality. Therefore, investing time upfront to ensure accurate measurements and tolerances will pay off significantly during production runs.

Moreover, precise molds contribute to reduced material waste—a critical factor when working with expensive injection moldable plastics. When every ounce counts, having a finely tuned mold minimizes excess material usage while maximizing output quality. This precision not only enhances product integrity but also fosters customer trust by delivering consistent results across multiple batches.

Techniques to Optimize Plastic Injection Molding Mold

To elevate your prototype plastic injection molding game, employing specific techniques can make a world of difference in optimizing your molds’ performance. First off, simulation software can be an invaluable tool; it allows designers to visualize how molten plastic flows within the cavity before physical production begins. This foresight helps identify potential issues early on.

Another technique involves using multi-cavity molds which enable simultaneous production of several parts per cycle—this approach dramatically increases efficiency without sacrificing quality in your plastic molding process. Furthermore, integrating cooling channels within the design optimizes heat dissipation during solidification; quicker cooling times lead to faster cycle rates and improved throughput.

Finally, regularly reviewing and updating your designs based on feedback from previous runs can help you stay ahead in a competitive landscape where prototype injection molding technology continually evolves. By embracing these techniques alongside a commitment to precision, you’ll be well on your way to mastering effective mold design!

Rapid Prototyping Techniques

In the realm of product development, rapid prototyping techniques have become indispensable, especially when it comes to prototype injection molding. This approach allows designers and engineers to quickly create and test prototypes before moving into full-scale production. By leveraging the efficiency of injection molding, teams can iterate designs faster and more effectively than with traditional methods.

Comparing Traditional Methods to Injection Molding

Traditional prototyping methods often involve labor-intensive processes such as handcrafting or machining, which can be time-consuming and costly. In contrast, prototype injection molding streamlines this process by utilizing automated machinery that creates precise molds for plastic parts in a fraction of the time. Additionally, while traditional techniques might limit material choices and complexity, injection molding opens up a world of possibilities with various injection moldable plastics that can accommodate intricate designs.

The speed at which plastic injection molding produces prototypes is a game-changer for industries needing rapid turnaround times. With conventional methods taking weeks or even months, the ability to produce high-quality prototypes in days enhances agility in product development cycles. This shift not only accelerates innovation but also allows businesses to respond swiftly to market demands.

Benefits of Rapid Prototyping with Injection Molding

One significant advantage of rapid prototyping using injection molding is the unparalleled precision it offers through mold plastic injection technology. The accuracy achieved ensures that prototypes closely resemble the final product, allowing for realistic testing and evaluation before mass production begins. Moreover, this precision minimizes costly adjustments later in the manufacturing process.

Another benefit lies in cost efficiency; while initial setup costs may seem high due to mold creation, the long-term savings from reduced waste and faster production times often outweigh these expenses. Prototype plastic injection molding also enables manufacturers to experiment with different materials without committing fully until they find the perfect fit for their application needs. This flexibility fosters innovation as teams can test multiple iterations without breaking the bank.

Furthermore, using prototype injection molding significantly reduces time-to-market for new products by enabling quick iterations based on feedback from stakeholders or end-users during testing phases. The combination of speed, cost-effectiveness, and adaptability makes this method an attractive choice for companies looking to maintain a competitive edge in their respective markets.

Case Studies of Successful Prototypes

Several successful case studies highlight how companies have harnessed prototype injection molding to revolutionize their product development processes. One notable example is a leading automotive manufacturer that utilized plastic injection molding techniques to rapidly develop interior components for a new vehicle model. By employing prototype plastic injection molding early in their design phase, they were able to identify design flaws quickly and make necessary adjustments before full-scale production began.

In another instance, a consumer electronics company leveraged this technology to create ergonomic housings for handheld devices efficiently. The use of various types of injection moldable plastics allowed them not only to enhance user comfort but also reduce weight without compromising durability—key factors that contributed significantly to their product's market success.

These case studies illustrate how effective rapid prototyping with prototype injection molding can lead not only to improved design outcomes but also substantial gains in overall productivity and profitability across diverse industries.

Quality Assurance in Prototype Plastic Injection Molding

Quality assurance is a crucial element in the realm of prototype injection molding, as it ensures that the final products meet the expected standards and specifications. The process involves a series of checks and balances throughout the production cycle, from initial design to final output. By adhering to best practices, manufacturers can minimize defects and optimize performance in plastic injection molding.

Best Practices for Ensuring Quality

To ensure quality in prototype plastic injection molding, it is essential to start with thorough material selection. Choosing high-quality injection moldable plastics that suit the specific application can significantly impact the final product's durability and functionality. Additionally, implementing regular maintenance schedules for molds and machinery helps prevent wear and tear that could lead to inconsistencies in production.

Another best practice is conducting regular inspections during the manufacturing process. This includes monitoring temperature, pressure, and cycle times to ensure they remain within prescribed limits for optimal mold plastic injection performance. Lastly, incorporating feedback loops from testing prototypes allows for continuous improvement of processes while addressing any issues before full-scale production begins.

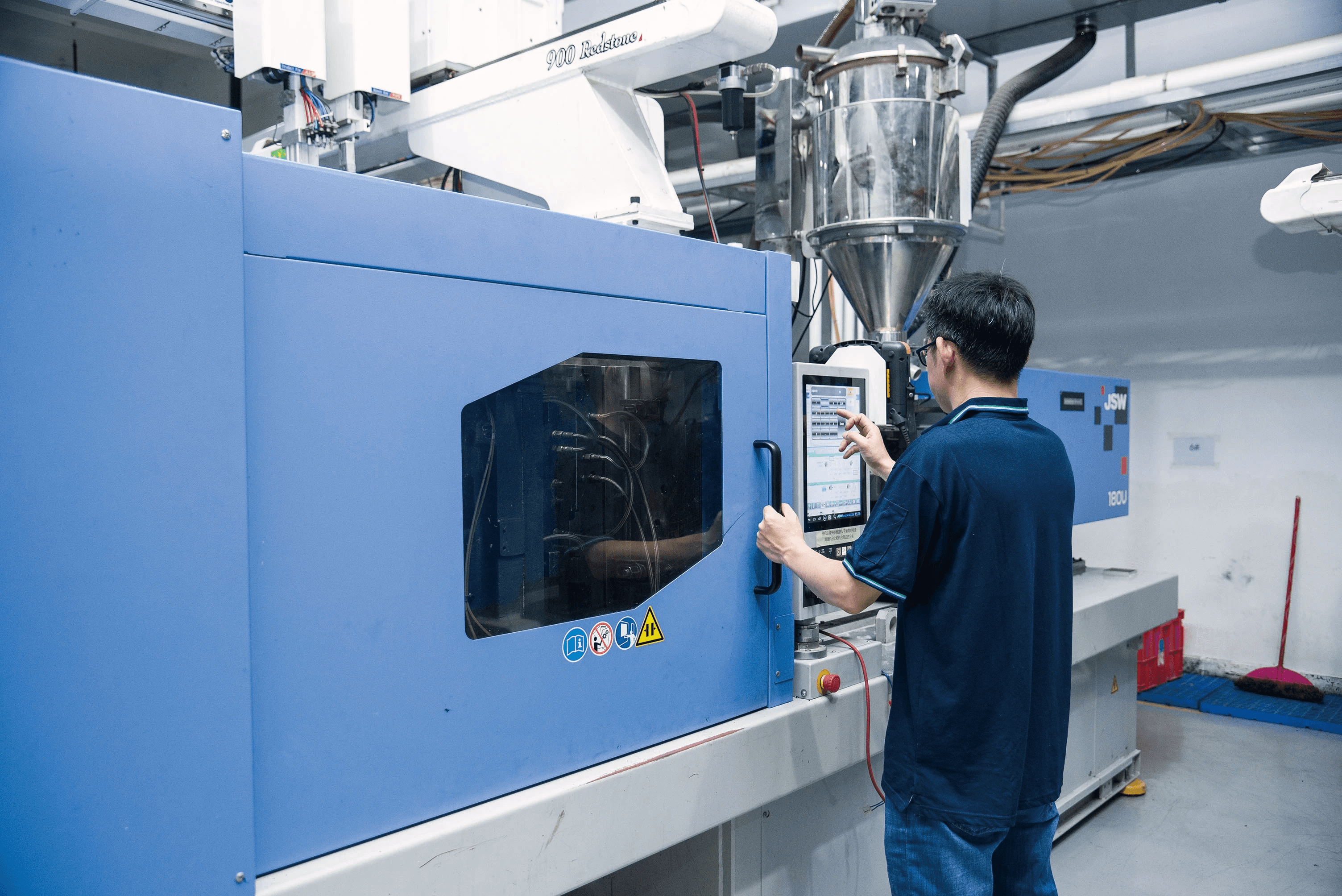

The Baoyuan Approach to Quality Control

At Baoyuan, quality control is not just a checkbox; it's woven into every aspect of our prototype injection molding process. Our approach emphasizes a blend of advanced technology and skilled craftsmanship, ensuring that every step—from design validation to final inspection—meets stringent quality standards. Through rigorous testing protocols, we guarantee that our plastic injection molding molds produce parts with precision and consistency.

We utilize state-of-the-art equipment coupled with experienced technicians who are trained to identify potential issues early on. This proactive stance on quality allows us to address concerns before they escalate into costly problems down the line. By fostering a culture of accountability among our team members, we ensure that quality remains at the forefront of all operations related to prototype plastic injection molding.

Common Issues and Troubleshooting

Even with robust systems in place, common issues can arise in prototype injection molding that require swift troubleshooting techniques. One prevalent problem is warping or distortion during cooling; this often stems from uneven temperature distribution within the mold plastic injection system or incorrect cooling rates for specific materials used in plastic injection molding processes. Addressing these factors early on can save time and resources later.

Another frequent issue involves surface finish defects such as sink marks or flow lines on molded parts; these can be attributed to improper gate design or inadequate packing pressure during filling cycles. Regularly reviewing mold designs against industry best practices helps mitigate these risks effectively while ensuring optimal results when utilizing various types of injection moldable plastics.

Lastly, maintaining open communication between design teams and production staff is vital for identifying potential challenges before they impact overall product quality significantly—after all, collaboration often leads to innovative solutions!

Conclusion

In the ever-evolving world of manufacturing, prototype injection molding stands out as a pivotal technique that is shaping the future of product development. As industries continue to embrace innovation, the significance of this method in creating high-quality prototypes cannot be overstated. By leveraging advancements in materials and technology, businesses can enhance their product offerings through efficient and effective plastic injection molding processes.

Future Trends in Prototype Injection Molding

The future of prototype injection molding is bright, with several trends poised to redefine how products are developed. One major trend is the integration of sustainable practices, leading to the use of eco-friendly injection moldable plastics that reduce environmental impact without compromising quality. Additionally, advancements in 3D printing technology are beginning to influence mold design and production methods, allowing for faster iterations and more complex geometries in prototype plastic injection molding.

Another exciting development is the rise of smart manufacturing techniques that utilize IoT (Internet of Things) technologies for real-time monitoring and data analytics during the plastic injection molding process. This ensures higher precision and quality control while minimizing waste and downtime. As companies invest in these innovative solutions, we can expect a significant transformation in how prototype injection molding contributes to rapid product development cycles.

Enhancing Efficiency in Production

To stay competitive, manufacturers must continually seek ways to enhance efficiency in production processes related to plastic molding. Streamlining operations through automation and advanced machinery can significantly reduce cycle times while maintaining high standards for quality assurance. The implementation of lean manufacturing principles also plays a crucial role by eliminating waste and optimizing resource allocation during the mold plastic injection process.

Moreover, collaboration between design teams and production engineers can lead to more effective designs that facilitate easier mold creation and maintenance. By focusing on creating efficient workflows within prototype plastic injection molding projects, companies can not only save time but also lower costs associated with material usage and labor. Ultimately, increased efficiency translates into faster time-to-market for new products.

The Impact of Technology on Plastic Molding Techniques

Technology has had an undeniable impact on various aspects of plastic injection molding techniques over recent years. The introduction of advanced simulation software allows designers to predict potential issues before physical molds are produced, thereby reducing costly errors during production runs. Additionally, improvements in computer-aided design (CAD) tools enable more intricate designs that were once thought impossible with traditional methods.

Furthermore, innovations such as multi-material printing offer exciting possibilities for producing prototypes with diverse properties using a single mold process—an advantage that could revolutionize prototype injection molding applications across multiple sectors including automotive, consumer goods, and medical devices. As technology continues to advance at an unprecedented pace, it will undoubtedly shape the landscape of plastic injection molding techniques for years to come.