Introduction

In the world of plastic injection molding, cooling time plays a pivotal role in determining the quality and efficiency of the final product. Cooling time in injection molding refers to the period required for molten plastic to solidify within a mold after it has been injected. This crucial phase not only affects the cycle time but also influences the dimensional accuracy and surface finish of plastic products.

What is Cooling Time in Injection Molding

Cooling time in injection molding is essentially the duration needed for injected molten plastic to cool down sufficiently to retain its shape once removed from the mold. The cooling process involves heat transfer from the hot plastic to the cooler mold surfaces, which ultimately solidifies the material into its final form. Understanding this process is vital for manufacturers who aim to optimize production cycles while ensuring high-quality outcomes.

Importance of Cooling Time

The importance of cooling time cannot be overstated; it directly impacts both productivity and product quality in injection molding operations. An adequately managed cooling phase can reduce cycle times, allowing manufacturers to produce more parts in less time, which is especially critical in high-volume production scenarios. Additionally, improper cooling can lead to defects such as warping or surface imperfections, affecting not just aesthetics but also functional performance of molded plastic products.

Factors Affecting Cooling Time

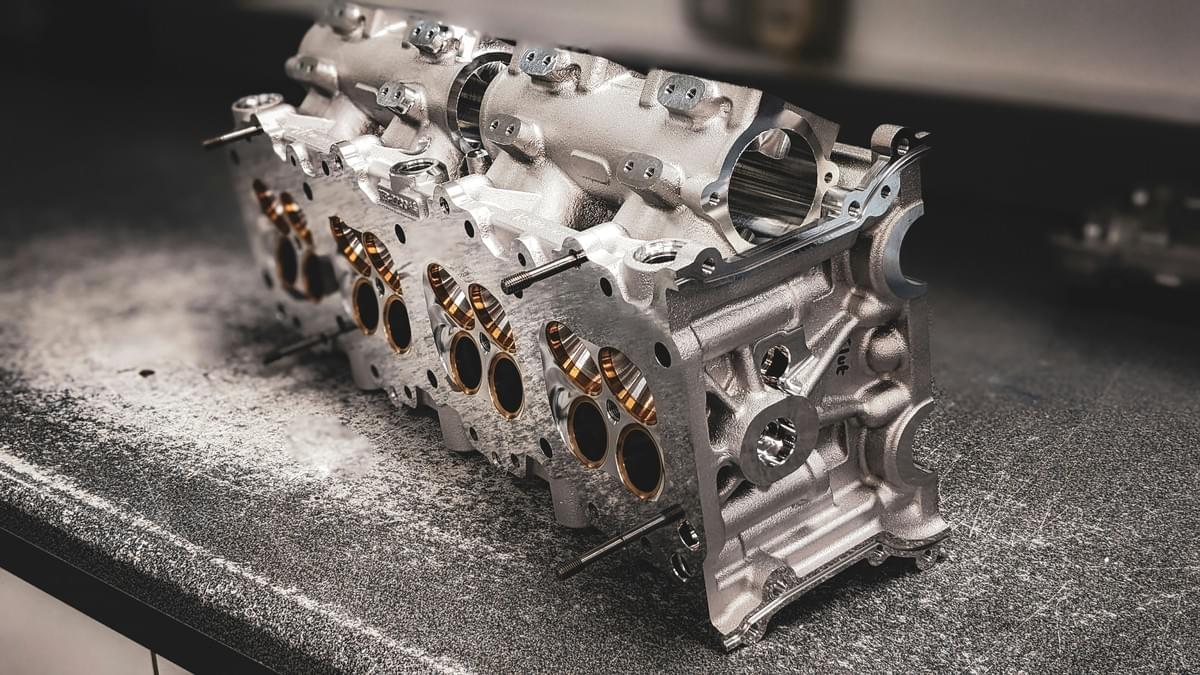

Several factors influence cooling time during injection molding processes, including material properties, mold design, and environmental conditions. The type of injection moldable plastics used plays a significant role; some materials cool faster than others due to their thermal conductivity characteristics. Moreover, factors like wall thickness and part geometry can complicate heat dissipation patterns within a plastic injection molding mold, further affecting overall cooling efficiency and effectiveness.

The Science Behind Cooling Time

Understanding the science behind cooling time in injection molding is crucial for producing high-quality plastic products. The cooling phase is where molten plastic transitions into a solid state, and this process is influenced by various factors including heat transfer, material properties, and mold design. A well-optimized cooling time can significantly enhance production efficiency and reduce defects in molded parts.

Heat Transfer in Injection Molding

Heat transfer plays a pivotal role in determining the cooling time in injection molding. When molten plastic is injected into the mold, it carries a substantial amount of thermal energy that needs to dissipate for the part to solidify properly. This heat transfer occurs through conduction, convection, and radiation; however, conduction—where heat moves directly from the hot plastic to the cooler mold—is typically the most significant mechanism at play.

The efficiency of this heat transfer process directly impacts how quickly cooling occurs and can be influenced by several factors such as mold temperature, material thermal conductivity, and surface area contact between the plastic and the mold. For instance, using materials with higher thermal conductivity can enhance heat dissipation rates, thereby reducing overall cooling time in injection molding. Understanding these principles allows manufacturers to fine-tune their processes for optimal results.

Role of Injection Moldable Plastics

Injection moldable plastics are specifically formulated to withstand high temperatures during processing while also providing desirable mechanical properties once cooled. The choice of plastic plays a critical role in how effectively it cools within the mold; some materials cool faster than others due to their inherent thermal properties. Polymers like polypropylene or polystyrene may have different cooling profiles compared to engineering plastics like ABS or nylon.

Moreover, each type of injection moldable plastic has its own melting point and specific heat capacity which dictate how long it takes for it to transition from liquid to solid form during production cycles. Selecting an appropriate resin not only influences cooling time but also affects part quality and performance characteristics post-cooling—making material selection an essential consideration in plastic injection molding processes.

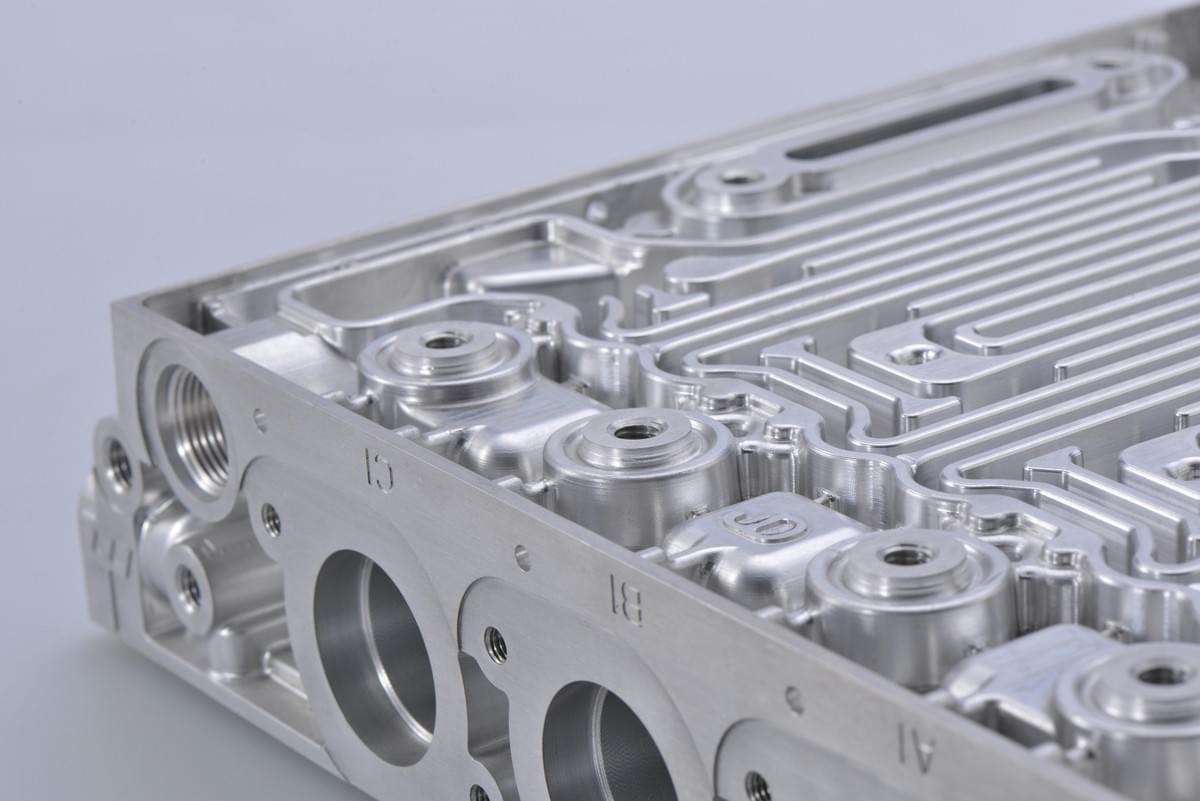

Cooling Channels: Design and Function

Cooling channels are integral components of any effective plastic injection molding setup; they are designed specifically to facilitate efficient heat removal from molten plastics during the cooling phase. The design of these channels—such as their size, shape, spacing, and placement—can dramatically influence both cooling time in injection molding and overall cycle times for production runs. A well-designed system ensures uniform temperature distribution across all areas of the molded part.

For example, strategically placed conformal cooling channels can help minimize hotspots that lead to warping or defects while maximizing surface contact with coolant mediums like water or oil used within these systems. Additionally, advancements such as 3D printing technology allow for more complex channel designs that were previously unattainable with traditional manufacturing methods—further optimizing heating/cooling dynamics within molds used for producing high-quality plastic products.

Measuring Cooling Time

Measuring cooling time in injection molding is crucial for achieving optimal production efficiency and product quality. Accurate measurement ensures that the plastic products being manufactured meet the required specifications without defects caused by improper cooling. By understanding how to effectively measure cooling time, manufacturers can significantly enhance their plastic molding processes.

Techniques for Accurate Measurement

To achieve accurate measurements of cooling time in injection molding, various techniques can be employed. One common method involves using thermocouples, which are placed at strategic locations within the mold to monitor temperature changes during the cooling phase. Additionally, thermal imaging cameras can provide a real-time view of temperature distributions across the mold surface, allowing operators to identify hot spots that may lead to uneven cooling.

Another effective technique is computational fluid dynamics (CFD), which simulates heat transfer and fluid flow within the mold. This approach helps predict how different factors—such as wall thickness and part geometry—affect cooling time for specific injection moldable plastics. By combining these techniques, manufacturers can develop a comprehensive understanding of their cooling processes and make informed adjustments.

Tools Used in the Industry

The industry utilizes a variety of tools for measuring and managing cooling time in injection molding processes. For instance, data loggers are commonly used to record temperature variations throughout production runs, providing valuable insights into how long it takes for molds to cool adequately after each cycle. These devices help establish baseline data that can be analyzed for trends over time.

In addition to data loggers, specialized software programs designed for plastic injection molding analysis play a significant role in optimizing cooling times. These tools often include modules that allow engineers to input parameters such as material type and part design, generating predictive models that highlight potential issues with heat dissipation or excessive cycle times. Such software not only streamlines the measurement process but also aids in refining mold designs for better performance.

Common Pitfalls in Measurement

While measuring cooling time is essential, there are several common pitfalls that manufacturers must avoid to ensure accuracy and reliability. One frequent mistake involves overlooking variations in ambient conditions; fluctuations in shop temperatures or humidity levels can significantly impact cooling rates of injection moldable plastics during production runs. Ignoring these environmental factors may lead to inconsistent results and subpar product quality.

Another pitfall arises from inadequate placement of measurement devices like thermocouples or sensors within the molds themselves; if these instruments are not positioned correctly, they may fail to capture critical temperature changes accurately throughout the entire process. Furthermore, relying solely on one measurement technique without corroborating it with others can lead to misleading conclusions about actual cooling times needed for effective plastic injection molding.

By staying aware of these common pitfalls and employing best practices when measuring cooling time in injection molding processes, manufacturers can enhance their overall efficiency while producing high-quality plastic products.

Calculating Cooling Time Effectively

Calculating the cooling time in injection molding is a crucial step in optimizing the production of plastic products. It involves understanding various factors, including the type of injection moldable plastics used and the specific design of the mold plastic injection system. Accurate calculations can significantly enhance efficiency and reduce production costs, making it an essential skill for anyone involved in plastic injection molding.

Formulas for Different Plastics

Commonly used formulas take into account specific heat capacities and thermal conductivities of various injection moldable plastics. For instance, a widely used formula is:

\[ \text{Cooling Time} = \frac{(T_{m} - T_{f}) \times V}{k} \]

where \(T_{m}\) is the melt temperature, \(T_{f}\) is the final temperature, \(V\) is the volume of the part, and \(k\) represents thermal conductivity. By applying these formulas accurately, manufacturers can better predict cooling times and streamline their processes.

The Role of Wall Thickness

Wall thickness plays a pivotal role in determining cooling time during plastic molding processes. Thicker walls retain heat longer than thinner ones, resulting in extended cooling times for parts with substantial wall thicknesses. This means that when designing a plastic injection molding mold, engineers must consider how variations in wall thickness will impact overall cycle times and product quality.

Moreover, balancing wall thickness with structural integrity is key; too thin may lead to defects while too thick can unnecessarily prolong cooling time in injection molding cycles. Therefore, understanding this relationship helps designers create efficient molds that meet both performance and aesthetic requirements without compromising on speed.

Impact of Part Geometry

Part geometry significantly influences cooling time during plastic injection processes as well; complex shapes often trap heat more effectively than simpler designs. Features like deep ribs or intricate patterns can create uneven cooling rates within different sections of a single molded part—leading to warping or other quality issues if not managed correctly.

To mitigate these risks, engineers should strive for uniformity in part geometry wherever possible while also considering how design choices affect heat dissipation throughout the entire piece during its transition from molten state to solid form. Ultimately, optimizing part geometry not only enhances aesthetics but also reduces cycle times and improves overall productivity within plastic molding operations.

Best Practices for Optimizing Cooling Time

Optimizing cooling time in injection molding is crucial for enhancing production efficiency and ensuring the quality of plastic products. By implementing best practices, manufacturers can significantly reduce cycle times while maintaining the integrity of injection moldable plastics. This section explores effective strategies to achieve optimal cooling time in plastic injection molding processes.

Adjusting Machine Settings

The first step to optimizing cooling time in injection molding is adjusting machine settings. Parameters such as injection speed, pressure, and temperature can dramatically impact how quickly a mold cools down after filling with molten plastic. By fine-tuning these settings based on the specific characteristics of the mold plastic injection process, operators can minimize cooling time while preventing defects like warping or incomplete fills.

Moreover, using a temperature controller can help maintain consistent thermal conditions throughout the cycle, which is essential for achieving uniform cooling across all parts of a mold. This consistency not only shortens the overall cycle time but also enhances the final product's dimensional accuracy and surface finish. Therefore, regularly reviewing and adjusting machine settings is a vital practice for optimizing cooling time in plastic molding operations.

Selecting the Right Cooling Method

Choosing an appropriate cooling method is another critical factor that influences cooling time in injection molding. Various techniques exist, from conventional water-cooled channels to advanced methods like conformal cooling or air-assisted systems. Each method has its advantages and challenges; therefore, understanding their implications on heat transfer rates is essential when selecting the right approach for specific applications.

For instance, conformal cooling channels designed to match the contours of a mold can provide more efficient heat removal compared to traditional straight-line channels. This tailored approach allows for even temperature distribution throughout the mold cavity, significantly reducing cooling times while improving part quality. Ultimately, selecting an effective cooling method tailored to your specific needs can lead to substantial improvements in production efficiency and product reliability.

Case Study: Baoyuan's Successful Optimization

Baoyuan’s recent project exemplifies how strategic optimization of cooling time in injection molding can lead to impressive results. Faced with excessive cycle times that hindered productivity for their line of consumer goods, Baoyuan implemented several best practices focused on enhancing their plastic injection processes. By adjusting machine settings and integrating advanced conformal cooling solutions into their molds, they successfully reduced their average cycle time by 30%.

This optimization not only improved throughput but also resulted in higher-quality plastic products with fewer defects—a win-win situation! The case study illustrates how investing in both technology and expertise leads to significant advancements in managing cooling times effectively within any plastic molding operation.

Troubleshooting Cooling Time Issues

In the world of injection molding, cooling time is crucial for ensuring quality plastic products. When cooling time is not optimized, it can lead to various issues that affect the final product's integrity and appearance. Therefore, recognizing these problems early can save both time and resources.

Identifying Signs of Improper Cooling

Improper cooling during the injection molding process can manifest in several noticeable ways. One common sign is warping or distortion of the finished plastic products, which indicates uneven cooling across the part. Additionally, if you notice surface defects like sink marks or voids, it's likely a sign that the cooling time in injection molding was insufficient or unevenly distributed.

Another indicator is longer cycle times than expected; if your production schedule seems to be dragging on without a clear reason, improper cooling might be at play. This could also lead to increased scrap rates as defective parts pile up due to inadequate mold plastic injection processes. Lastly, excessive pressure buildup in the mold can also signal that heat isn't being dissipated effectively, causing delays and potential damage to your equipment.

Solutions for Common Problems

Once you've identified signs of improper cooling time in injection molding, it's essential to implement effective solutions promptly. First off, adjusting machine settings such as temperature and pressure can help optimize heat transfer within your plastic injection molding mold. Fine-tuning these parameters ensures that the material cools evenly and reduces defects in your final products.

Another solution involves redesigning cooling channels within the mold itself; ensuring they are strategically placed allows for more efficient heat dissipation from all areas of the part being molded. Using advanced simulation software can aid in visualizing how changes may impact overall cooling efficiency before making physical adjustments. Lastly, consider using high-performance injection moldable plastics designed for better thermal conductivity—this choice could significantly enhance your overall production quality.

When to Consult Experts Like Baoyuan

While many issues related to cooling time can be resolved with some adjustments and troubleshooting techniques, there are instances where expert intervention becomes necessary. If you've tried various solutions but still struggle with consistent quality or cycle times in your plastic molding operations, it might be time to consult professionals like Baoyuan who specialize in optimizing injection molding processes.

Experts bring valuable insights into complex problems that may not be immediately apparent through standard troubleshooting measures alone—like identifying subtle design flaws or suggesting advanced materials tailored for specific applications within plastic injection molding molds. They also stay updated on industry trends and technologies that could further enhance your production capabilities while reducing costs associated with poor quality control.

In summary, addressing issues related to cooling time requires vigilance and expertise—but knowing when to seek outside help could make all the difference between mediocre results and exceptional ones.

Conclusion

In the world of injection molding, understanding cooling time is crucial for producing high-quality plastic products efficiently. Cooling time in injection molding directly impacts cycle times, part quality, and overall production costs. By optimizing this critical phase, manufacturers can enhance their competitiveness and ensure that their plastic injection processes yield the best results.

Recap: Importance of Cooling Time

Cooling time plays a pivotal role in the injection molding process, as it determines how quickly molten plastic solidifies within the mold. If cooling time is too short, it can lead to defects such as warping or incomplete filling, while excessive cooling can extend cycle times unnecessarily. Thus, mastering cooling time in injection molding is essential for achieving optimal part quality and productivity.

Best Practices for Injection Molding

To optimize cooling time effectively, several best practices should be followed during the injection molding process. First and foremost, selecting appropriate cooling methods tailored to specific injection moldable plastics can significantly enhance efficiency. Additionally, adjusting machine settings based on part geometry and wall thickness will help fine-tune the cooling process for better outcomes in plastic molding.

Final Thoughts on Plastic Molding Optimization

In conclusion, optimizing cooling time in injection molding is not just a technical necessity; it's a strategic advantage that can set manufacturers apart in a competitive market. By prioritizing best practices and leveraging advanced techniques like effective mold design and accurate measurement tools, businesses can improve their plastic products' quality while reducing costs. Embracing these strategies will ultimately lead to more efficient plastic injection processes and greater success in the industry.