Introduction

In the fast-evolving world of automotive manufacturing, understanding automotive plastics parts is crucial for both efficiency and performance. These components, primarily produced through plastic injection molding services, are integral to modern vehicles, providing lightweight solutions without compromising strength or durability. With the growing reliance on injection molded plastic components, it’s essential to grasp the nuances of these materials and their applications in the automotive sector.

Understanding Automotive Plastics Parts

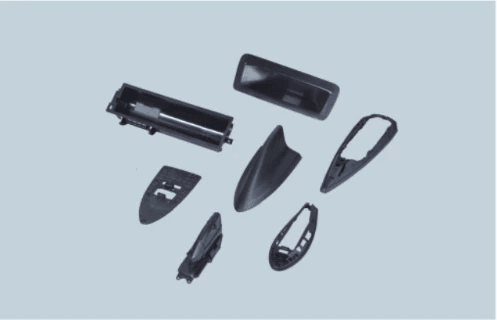

Automotive plastics parts encompass a wide range of components used in vehicles today, from dashboards to exterior panels. The use of injection moldable plastics allows manufacturers to create complex shapes and designs that enhance both functionality and aesthetics. As the industry shifts towards more sustainable practices, these materials also offer recycling potential that traditional metals do not.

The Importance of Choosing the Right Supplier

Selecting the right supplier for your automotive plastics parts can make or break your production process. A reliable supplier not only provides high-quality injection molding services but also ensures consistency in supply and innovation in design. With numerous options available, making an informed choice is vital to avoid costly delays and subpar products.

Key Attributes of Reliable Suppliers

When evaluating potential suppliers for injection moldable plastics, several key attributes should be considered. First and foremost is their experience in producing automotive plastics parts; a seasoned supplier will have a proven track record of delivering quality products on time. Additionally, strong customer service practices—such as effective communication and support—are essential for fostering a successful partnership that meets your manufacturing needs.

Evaluating Supplier Experience

When it comes to automotive plastics parts, the experience of a supplier can significantly influence the quality and reliability of your products. A seasoned supplier will not only understand the intricacies of plastic injection molding services but also be adept at navigating industry challenges. Therefore, evaluating a supplier's experience is crucial for ensuring that you receive high-quality injection molded plastic components.

Industry Reputation Matters

The reputation of a supplier in the automotive plastics parts sector speaks volumes about their capabilities and reliability. Companies with strong industry reputations often have a track record of delivering high-quality plastic injection services and satisfying customer needs effectively. When choosing a partner, consider seeking testimonials or reviews from other clients to gauge how well they manage their injection molding processes and customer relationships.

Years in Automotive Plastics Parts

Experience is not just about how long a company has been around; it’s also about the depth of knowledge they bring to the table regarding injection moldable plastics and their applications. Suppliers that have spent years in automotive plastics parts manufacturing typically possess invaluable insights into materials, production techniques, and market trends. This extensive experience can lead to better design choices and more efficient production methods, ultimately benefiting your project.

Case Studies of Supplier Success

To truly understand what makes a reliable supplier stand out in the realm of automotive plastics parts, examining case studies can be enlightening. Successful suppliers often showcase their achievements through detailed examples that highlight how they tackled specific challenges using innovative plastic injection solutions. These case studies not only demonstrate their expertise but also offer potential clients confidence in their ability to deliver quality results consistently.

Assessing Manufacturing Capabilities

When it comes to automotive plastics parts, assessing a supplier's manufacturing capabilities is crucial. This evaluation not only ensures that the supplier can meet your specific needs but also guarantees that they employ the latest techniques in plastic injection molding services. A reliable supplier should have a robust infrastructure and proven processes in place to produce high-quality injection molded plastic components.

Plastic Injection Molding Services Overview

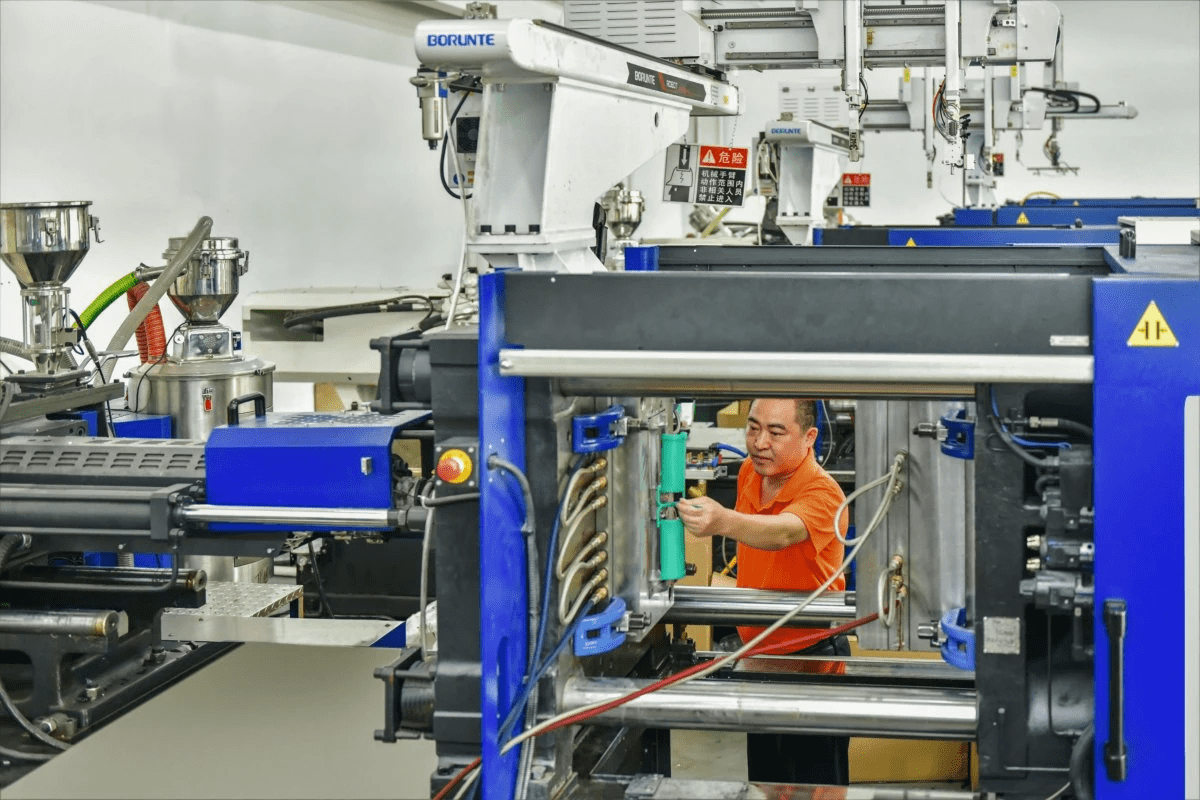

Plastic injection molding is a manufacturing process that involves injecting molten plastic into molds to create precise shapes and designs for automotive plastics parts. This technique allows for high-volume production with consistent quality, making it ideal for the automotive industry where durability and performance are paramount. Understanding the various plastic injection molding services available can help you choose a supplier that aligns with your project requirements.

A well-equipped manufacturer will offer diverse molding options, including multi-cavity molds and complex geometries, which are essential for producing intricate automotive plastics parts. Additionally, they should be able to handle various types of injection moldable plastics that cater to different applications within the automotive sector. This flexibility ensures that you receive components tailored specifically to your vehicle’s design and functionality.

Injection Moldable Plastics and Their Applications

Injection moldable plastics come in various types, each suited for specific applications within automotive manufacturing. Commonly used materials include acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and polypropylene (PP), all of which offer unique properties such as impact resistance, thermal stability, and lightweight characteristics. These qualities make them ideal candidates for producing durable automotive plastics parts like dashboards, bumpers, and interior trims.

The versatility of injection moldable plastics extends beyond aesthetics; they also play a vital role in enhancing vehicle performance by reducing weight while maintaining structural integrity. As manufacturers continue to innovate within this space, new materials are emerging that provide even greater resilience against environmental factors like UV exposure and temperature fluctuations. Thus, partnering with a supplier who understands these advancements is key to staying competitive in the automotive market.

Quality Control Processes in Production

Quality control processes are paramount when assessing potential suppliers of automotive plastics parts because they directly impact product reliability and safety standards. An effective quality assurance program encompasses every stage of production—from raw material selection through final inspection—ensuring consistency across all injection molded plastic components produced by the manufacturer.

Look for suppliers who utilize advanced testing methods such as tensile strength tests or thermal analysis on their injection molded products before delivery to guarantee compliance with industry standards. Additionally, certifications such as ISO 9001 indicate a commitment to maintaining high-quality practices throughout their operations—an essential factor when selecting your partner in producing critical automotive components.

By thoroughly evaluating these aspects of manufacturing capabilities—service offerings in plastic injection molding services, knowledge about different injection moldable plastics applications, and rigorous quality control processes—you’ll be better equipped to make an informed decision on your next supplier partnership.

Technology and Innovation in Production

In the ever-evolving landscape of automotive plastics parts, technology plays a pivotal role in enhancing production efficiency and product quality. The advancements in plastic injection molding services have transformed how manufacturers create injection molded plastic components, ensuring they meet stringent industry standards. By leveraging innovative techniques, suppliers can produce high-quality plastic components that are both durable and cost-effective.

Advancements in Injection Molding Techniques

The world of injection molding has seen significant advancements that have revolutionized the production of automotive plastics parts. Modern mold injection molding techniques now allow for greater precision, faster cycle times, and improved material properties. For instance, the introduction of multi-material injection molding enables the creation of complex parts with varying properties within a single process, making it easier to meet diverse automotive design requirements.

Furthermore, advancements such as gas-assisted injection molding enhance the structural integrity of components while reducing weight—an essential factor in the automotive industry focused on fuel efficiency. These innovative techniques not only improve performance but also reduce waste during production, aligning with sustainable manufacturing practices that many companies are striving for today.

Role of CAD Software in Mold Design

Computer-Aided Design (CAD) software has become an indispensable tool in designing molds for plastic injection processes. This technology allows engineers to create detailed 3D models of molds used for producing automotive plastics parts, facilitating precise adjustments before physical prototypes are made. By using CAD software, manufacturers can simulate the entire molding process to identify potential issues early on and optimize designs for better performance.

Moreover, CAD tools enable seamless collaboration among teams by providing a platform where designers and engineers can share ideas and modifications efficiently. The result is a faster turnaround time from concept to production while ensuring that every injection molded plastic component meets rigorous quality standards.

Impact of Technology on Cost-Effectiveness

Investing in advanced technologies significantly impacts the cost-effectiveness of producing automotive plastics parts through plastic injection services. Automation and robotics have streamlined many aspects of the manufacturing process—reducing labor costs while increasing output consistency across batches of injection molded products. This technological shift means that suppliers can offer competitive pricing without compromising on quality or delivery times.

Additionally, improved data analytics tools allow manufacturers to monitor production processes closely and make real-time adjustments that minimize waste and downtime. Consequently, businesses can achieve long-term savings through efficient use of resources while maintaining high standards in their injected moldable plastics offerings.

Customer Service and Support

In the world of automotive plastics parts, customer service and support can make or break a partnership. Suppliers who prioritize customer satisfaction tend to build long-lasting relationships with their clients, ensuring smooth operations and timely deliveries. This section will explore the essential aspects of customer service that should be considered when selecting a supplier for plastic injection molding services.

Availability of Technical Support

When dealing with injection molded plastic components, having access to reliable technical support is crucial. A knowledgeable support team can assist in troubleshooting issues related to mold injection molding, helping you optimize production processes and reduce downtime. Suppliers offering 24/7 technical assistance demonstrate their commitment to your success in the competitive automotive plastics parts industry.

Furthermore, technical support goes beyond just problem-solving; it includes guidance on choosing the right injection moldable plastics for specific applications. This ensures that you are utilizing materials that meet both performance and regulatory standards while maximizing efficiency in your manufacturing process. When evaluating suppliers, inquire about their technical support offerings; this could be a game-changer for your production line.

Supplier Communication Practices

Effective communication is the backbone of any successful partnership in the realm of automotive plastics parts. Suppliers should maintain transparent lines of communication regarding order status, lead times, and any potential issues that may arise during production. Regular updates help build trust and ensure that you are never left in the dark about your plastic injection orders.

Moreover, good communication practices extend to understanding your unique needs as a client. A supplier who takes time to listen and adapt their services accordingly shows they value your business relationship and are invested in providing quality plastic components tailored specifically for you. Look for suppliers who actively solicit feedback; this indicates a willingness to improve continuously.

Handling Returns and Warranty Services

Even with rigorous quality control processes in place, there may be instances where returns are necessary due to defects or discrepancies in injection molded plastic components. A supplier’s return policy can reveal much about their commitment to customer satisfaction within the automotive plastics parts sector. Look for clear guidelines on how returns are processed along with timelines for resolution—this will save you headaches down the road.

Additionally, warranty services play an essential role in maintaining peace of mind when investing in plastic injection molding services. A robust warranty not only protects your investment but also reflects a supplier's confidence in their products' durability and reliability over time. When assessing potential partners, make sure they offer comprehensive warranty options that align with industry standards.

Pricing and Value Assessment

When it comes to automotive plastics parts, pricing is a critical factor that can influence your choice of supplier. However, it’s not just about finding the lowest price; understanding the value you receive in return is equally important. A well-rounded pricing strategy considers quality, reliability, and overall service, ensuring that you get the best bang for your buck in plastic injection molding services.

Competitive Pricing Strategies

In the realm of automotive plastics parts, competitive pricing strategies can vary significantly among suppliers. Some may adopt a cost-leadership approach by minimizing production expenses while maintaining acceptable quality levels with injection molded plastic components. Others might focus on differentiation by offering unique features or superior customer service at a premium price point—ultimately allowing you to choose based on your specific needs and budget.

A supplier's ability to provide competitive prices often hinges on their manufacturing efficiencies and economies of scale achieved through advanced plastic injection techniques. For instance, companies specializing in mold injection molding might offer lower prices due to streamlined operations and bulk material purchases. It's essential to evaluate these strategies carefully to ensure you're not sacrificing quality for cost savings.

Understanding Cost Structures in Injection Molding

Understanding the cost structures involved in plastic injection molding is crucial for making informed decisions about automotive plastics parts procurement. The costs typically include raw materials, labor, overheads, tooling expenses for mold design, and maintenance costs associated with machinery used in producing injection moldable plastics. By breaking down these components, you can gain insights into where potential savings lie without compromising on quality.

Moreover, some suppliers may offer transparent pricing models that clarify how each element contributes to the final cost of production for injection molded plastic components. This transparency allows you to compare different suppliers more effectively while ensuring there are no hidden fees lurking around the corner. Being well-informed about these structures will empower you as a buyer to negotiate better terms or select options that align with your budgetary constraints.

Long-Term Value over Short-Term Savings

While short-term savings can be appealing when sourcing automotive plastics parts through cheap deals or one-off discounts, it’s vital to consider long-term value instead. Investing in high-quality plastic injection services may come at a higher upfront cost but can lead to significant benefits such as reduced failure rates and lower maintenance costs over time for your injection molded plastic components.

Choosing suppliers known for their durability and reliability means fewer replacements and repairs down the line—essentially saving money in the long run despite initial expenses being higher than competitors offering cheaper alternatives. Ultimately, balancing immediate financial considerations with strategic foresight will help ensure that your investments yield fruitful returns as your business grows.

Conclusion

In summary, the right partnership in the automotive plastics parts industry can significantly influence your project's success. Choosing a reliable supplier like Baoyuan ensures access to high-quality plastic injection molding services and a wealth of experience in producing injection molded plastic components. By aligning with a trusted partner, you can enhance your production capabilities while maintaining cost-effectiveness.

Benefits of Partnering with Baoyuan

Their expertise in plastic injection and commitment to quality means that you receive top-notch injection moldable plastics tailored to your specific needs. Additionally, Baoyuan's innovative approach to mold injection molding ensures that you benefit from the latest advancements in manufacturing technology.

Moreover, their extensive experience within the industry translates into streamlined processes and reduced lead times for your projects. With a focus on customer satisfaction, Baoyuan prioritizes communication and support throughout the production cycle, making them an invaluable ally for businesses looking to succeed in a competitive market. Ultimately, choosing Baoyuan as your supplier not only guarantees quality but also fosters a lasting partnership built on trust and mutual growth.

How to Verify Supplier Credentials

When selecting a supplier for automotive plastics parts, verifying credentials is crucial for ensuring reliability and quality. Start by researching their industry reputation through customer testimonials and case studies showcasing successful projects involving injection molded plastic components. Additionally, check certifications related to manufacturing standards that demonstrate compliance with safety regulations and quality benchmarks.

Another effective method is visiting their manufacturing facility if possible; this firsthand observation allows you to assess their capabilities regarding plastic injection molding services directly. Engaging in open discussions about their processes provides valuable insights into their operational efficiency and commitment to innovation in mold injection molding techniques. Remember that due diligence now will save you headaches later when dealing with production challenges.

Future Trends in Automotive Plastics Parts Industry

The automotive plastics parts industry is poised for exciting developments driven by technological advancements and evolving consumer demands. One significant trend is the increasing use of lightweight materials aimed at improving fuel efficiency while maintaining structural integrity; this shift will enhance the adoption of advanced injection moldable plastics across various applications within vehicles. Furthermore, sustainability initiatives are gaining traction as manufacturers seek eco-friendly alternatives that minimize environmental impact during production.

Additionally, innovations like 3D printing technology are revolutionizing design processes for mold injection molding by allowing rapid prototyping of complex shapes without extensive tooling costs or time delays. As electric vehicles become more prevalent, there will be an ongoing demand for specialized plastic components designed specifically for these new models' unique requirements—an opportunity ripe for suppliers who adapt quickly to market changes! Embracing these trends ensures that your business remains competitive while capitalizing on future growth opportunities within the automotive sector.