Introduction

Weld lines in injection molding are a common phenomenon that can significantly impact the quality and aesthetics of molded parts. These lines, often seen as faint marks or seams on the surface of a plastic part, occur when two flows of molten plastic meet and fail to fuse completely. Understanding how these weld lines form is crucial for anyone involved in the design and production of injection moldable plastics.

Understanding Weld Lines in Injection Molding

Weld lines arise during the injection molding process when multiple flow fronts converge, leading to incomplete fusion at their intersection. This can result from various factors, including material properties, mold design for injection molding, and processing conditions. Recognizing how these weld lines develop helps manufacturers address potential issues early on, ensuring higher-quality products.

Importance of Identifying Key Causes

Identifying the key causes of weld lines in injection molding is essential for optimizing production processes and enhancing product quality. Factors such as polymer type, viscosity, flow rates, and even gate locations can influence the formation of these unwanted seams. By pinpointing these causes, manufacturers can implement targeted strategies to reduce or eliminate weld line occurrences.

Common Myths Debunked

There are several myths surrounding weld lines in injection molding that can lead to misunderstandings about their origins and remedies. For instance, some believe that increasing pressure during injection will always eliminate weld lines; however, this is not necessarily true—too much pressure can sometimes exacerbate the issue instead. By debunking these myths and focusing on factual information regarding plastic for molding processes, we pave the way for more effective solutions.

What are Weld Lines?

Weld lines in injection molding are an essential aspect of understanding the quality and integrity of molded products. These lines, often seen as undesirable defects, occur when two or more flow fronts meet during the injection process. Recognizing how these weld lines form and their implications can significantly enhance the quality of mold plastic injection projects.

Defining Weld Lines in Injection Molding

Weld lines in injection molding refer to visible seams or marks that appear on the surface of a molded part where two polymer flows converge. These lines can be weak points in the structure, impacting both aesthetics and mechanical properties of the final product made from injection moldable plastics. Understanding this phenomenon is crucial for manufacturers aiming to produce high-quality plastic for molding applications.

How Weld Lines Form During the Process

Weld lines form when molten polymer flows from different gates or sections of a mold converge and cool down, resulting in a bond that may not be as strong as the surrounding material. Factors such as temperature discrepancies, flow rates, and viscosity play significant roles in how effectively these flows merge. If conditions aren’t optimal during plastic injection molding mold processes, weld lines may manifest as weak joints that compromise product performance.

Real-World Examples of Weld Line Issues

Consider a case where a consumer electronics housing is produced using plastic injection molding; if weld lines are present, they might lead to cracks under stress or impact over time. In another example, automotive components manufactured with inadequate attention to weld line formation could result in failures during operation, leading to costly recalls. Such real-world scenarios highlight how critical it is to manage weld lines effectively during mold design for injection molding projects.

Material Choices Impacting Weld Lines

The Role of Polymer Type

The type of polymer selected for a project plays a critical role in determining the formation and visibility of weld lines in injection molding. For instance, amorphous polymers tend to exhibit better flow characteristics than crystalline ones, which can lead to smoother transitions and less noticeable weld lines. Additionally, some polymers are more prone to warping or shrinking during cooling; understanding these traits is essential when designing a mold plastic injection process.

Selecting the right polymer not only impacts weld line visibility but also affects overall part strength and durability. For example, polycarbonate is often favored for its toughness, but it may require careful consideration regarding flow rates to minimize weld line issues. Thus, choosing an appropriate polymer type is crucial for achieving optimal results in plastic injection molding molds.

Importance of Viscosity and Flow Rate

Viscosity and flow rate are two peas in a pod when discussing weld lines in injection molding; they directly affect how well materials fill the mold cavity before cooling begins. High viscosity materials can struggle to flow efficiently through gates and channels, leading to incomplete filling and pronounced weld lines as different material streams converge. On the other hand, low-viscosity plastics can help create smoother surfaces with fewer defects.

Adjusting viscosity through temperature control or selecting inherently more fluid polymers can significantly reduce issues associated with weld lines in injection molding processes. Moreover, optimizing flow rates ensures that material fills the mold uniformly without leaving gaps that could lead to weak spots or visual imperfections at junctions where flows meet. Therefore, understanding viscosity's impact on flow dynamics is essential for effective mold design for injection molding.

How Additives Influence Weld Line Formation

Additives play an important role in enhancing the performance of injection moldable plastics while simultaneously influencing their tendency to form weld lines during processing. Certain additives can improve flow characteristics or increase impact resistance without compromising clarity or surface finish—factors that are essential when considering aesthetic aspects of molded parts with visible welds. For instance, using processing aids can enhance fluidity and reduce shear stress during filling.

However, not all additives have beneficial effects; some may inadvertently contribute to increased melt viscosity or alter crystallization behavior negatively impacting overall part quality by promoting more pronounced weld lines in injection molding applications. Careful selection and testing of additives ensure that they serve their intended purpose without introducing new challenges during production runs involving complex geometries or high-performance requirements for plastic for molding projects.

In summary, material choices significantly impact the formation of weld lines during plastic injection molding processes—be it through polymer type selection, managing viscosity and flow rate effectively or incorporating suitable additives into formulations tailored specifically for intended applications.

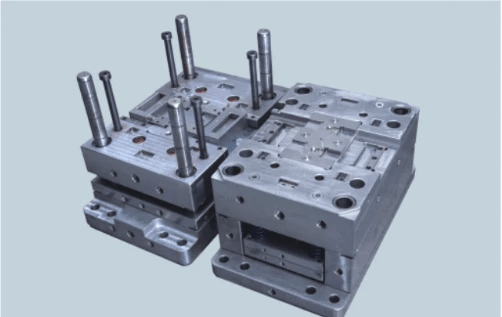

Mold Design Considerations

Designing for Optimal Flow

The foundation of effective mold design for injection molding lies in ensuring optimal flow characteristics of the molten plastic. An efficient design allows the plastic for molding to travel smoothly through the cavity without creating turbulence, which is often a precursor to weld lines in injection molding. Designers should consider factors like channel geometry and dimensions to facilitate uninterrupted flow and minimize potential bottlenecks.

Incorporating features such as radii and draft angles can further enhance flow by reducing shear stress during filling. This approach also helps maintain uniformity in wall thickness, which is essential for preventing weak points where weld lines might form. Ultimately, a focus on optimal flow not only minimizes defects but also contributes to improved cycle times and overall productivity in plastic injection molding mold operations.

The Influence of Gate Location

Gate location is another critical factor that impacts weld line formation during the injection molding process. The placement of gates determines how molten material enters the mold cavity; poorly positioned gates can lead to uneven filling and increased chances of weld lines in injection molding artifacts appearing on finished products. Ideally, gates should be placed strategically to promote balanced filling across all sections of the mold.

By positioning gates closer to areas where multiple flows converge, designers can encourage better mixing and reduce potential weak points associated with weld lines. Additionally, using multiple gates or sequential gating techniques may help distribute pressure evenly throughout the cavity, further mitigating risks associated with uneven material distribution. Ultimately, thoughtful gate placement paves the way for cleaner finishes and higher-quality molded parts.

Importance of Venting in Reducing Weld Lines

Venting is often an overlooked aspect when discussing mold design for injection molding but is vital for minimizing weld lines in injection molding processes. Effective venting allows trapped air within the mold cavity to escape during filling; if air pockets are not released promptly, they can hinder material flow and lead to defects like incomplete fills or visible weld lines on finished components.

Designers should incorporate vents at strategic locations around the mold where air entrapment is likely while ensuring they do not interfere with part aesthetics or functionality. Proper venting reduces pressure buildup and enhances material flow dynamics—facilitating smoother transitions between different sections of molded parts made from various injection moldable plastics. When done right, venting becomes an unsung hero that contributes significantly to achieving seamless results while combating those pesky weld line issues.

Injection Molding Parameters to Adjust

When it comes to managing weld lines in injection molding, the parameters you choose can make all the difference. Adjusting temperature settings, pressure levels, and cycle times can lead to significant improvements in the quality of your molded parts. Let's dive into how each of these factors plays a role in minimizing weld line issues.

Temperature Settings and Their Effects

Temperature is a crucial factor in the injection molding process that directly affects weld lines in injection molding. Higher temperatures generally reduce viscosity, allowing for better flow of injection moldable plastics, which helps eliminate potential weld lines. However, overheating can lead to degradation of the plastic for molding, so finding that sweet spot is essential for optimal results.

Maintaining consistent barrel and mold temperatures ensures uniform cooling and solidification of the material as it flows through the cavity. If temperatures fluctuate too much during production, you may end up with inconsistent weld line formation or even defects that require costly rework. Therefore, closely monitoring your temperature settings is vital for achieving high-quality mold plastic injection outcomes.

Furthermore, different types of plastics have varying thermal properties; understanding these nuances allows you to tailor your temperature settings accordingly. For instance, some materials may require higher processing temperatures to achieve proper flow characteristics while others might benefit from lower settings to prevent premature solidification at critical junctions where weld lines are likely to form.

Pressure Levels and Their Impact on Weld Lines

Pressure levels play a significant role in shaping the outcome of your injection molding process and can greatly influence weld lines formation. High pressure helps force molten plastic into intricate mold designs while also promoting better fusion at joining points where two melt fronts meet—essentially reducing those pesky weld lines in injection molding. However, excessive pressure can cause other issues such as flash or warping.

Finding an optimal balance is key; if pressure levels are too low during filling, incomplete packing may occur leading to weak areas prone to defects like visible weld lines or structural weaknesses in molded parts. On the flip side, if pressures are excessively high during cooling or holding phases, this can result in stress concentrations that compromise part integrity over time.

It’s also worth noting that different polymers respond differently under varying pressure conditions—some might require higher pressures due to their inherent viscosity while others could be processed effectively at lower levels without sacrificing quality or increasing defect rates. Thus understanding how each specific material behaves under different pressures will empower you to make informed adjustments for improved results with every run.

Cycle Time and Cooling Considerations

Cycle time is another critical parameter that impacts both efficiency and quality when dealing with welding issues in plastic injection molding molds. Shortening cycle times can increase productivity but may inadvertently lead to inadequate cooling—resulting in poorly formed parts with visible weld lines or other defects due to uneven material distribution during solidification.

A well-designed cooling system within your mold design for injection molding is essential for maintaining consistent part quality throughout production runs; effective cooling not only minimizes cycle times but also ensures uniform temperature across all areas of the mold cavity which helps mitigate potential problems related specifically to welding points between melt fronts during filling phases.

Moreover, adjusting cycle times should take into consideration not just speed but also how well materials cool down after being injected into molds—the right balance will ultimately contribute towards achieving strong bonds between melted sections while minimizing any residual stresses caused by rapid changes within those regions where welds form most frequently!

In summary, fine-tuning these parameters—temperature settings, pressure levels, and cycle times—is vital when striving for flawless parts free from unwanted weld lines common among many types of injection moldable plastics today!

Troubleshooting Weld Lines Effectively

When it comes to tackling weld lines in injection molding, identifying the symptoms is your first step towards a solution. These unsightly marks can manifest in various ways, often leading to concerns about the quality and aesthetics of your finished product. Recognizing these symptoms early on can save you time and resources when it comes to resolving issues related to mold plastic injection.

Identifying Common Symptoms

Weld lines in injection molding typically appear as faint or dark lines where two flow fronts meet during the process. These imperfections can compromise both the visual appeal and structural integrity of your product, making them a significant concern for manufacturers using injection moldable plastics. Other common symptoms include inconsistent surface finish or weak spots that may lead to premature failure during use, particularly in high-stress applications.

Another telltale sign of weld line issues is a noticeable drop in mechanical properties at the weld line area compared to the rest of the part. This could result from improper flow rates or inadequate temperature settings during production, which affects how well the materials bond together when molded. Additionally, if you observe variations in color or texture along these lines, it's an indicator that adjustments are needed in your mold design for injection molding.

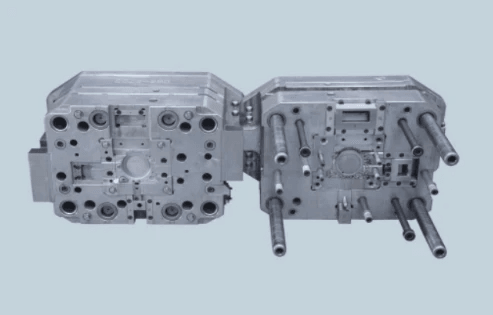

Solutions from the Baoyuan Team

The Baoyuan Team has developed several strategies for mitigating weld line problems effectively within plastic injection molding processes. First and foremost, optimizing flow dynamics through enhanced gate design can significantly reduce occurrences of weld lines by ensuring more uniform material distribution. Moreover, adjusting temperature settings is crucial; maintaining consistent melt temperatures helps achieve better fusion between flow fronts.

Another solution involves selecting appropriate materials; certain polymers have inherent properties that reduce susceptibility to weld lines when processed correctly. The team also emphasizes the importance of thorough testing and validation throughout production cycles—this proactive approach allows manufacturers to pinpoint issues before they escalate into larger problems down the line. Ultimately, working closely with experts like those at Baoyuan ensures that any challenges with welding during molding over molding are addressed swiftly and efficiently.

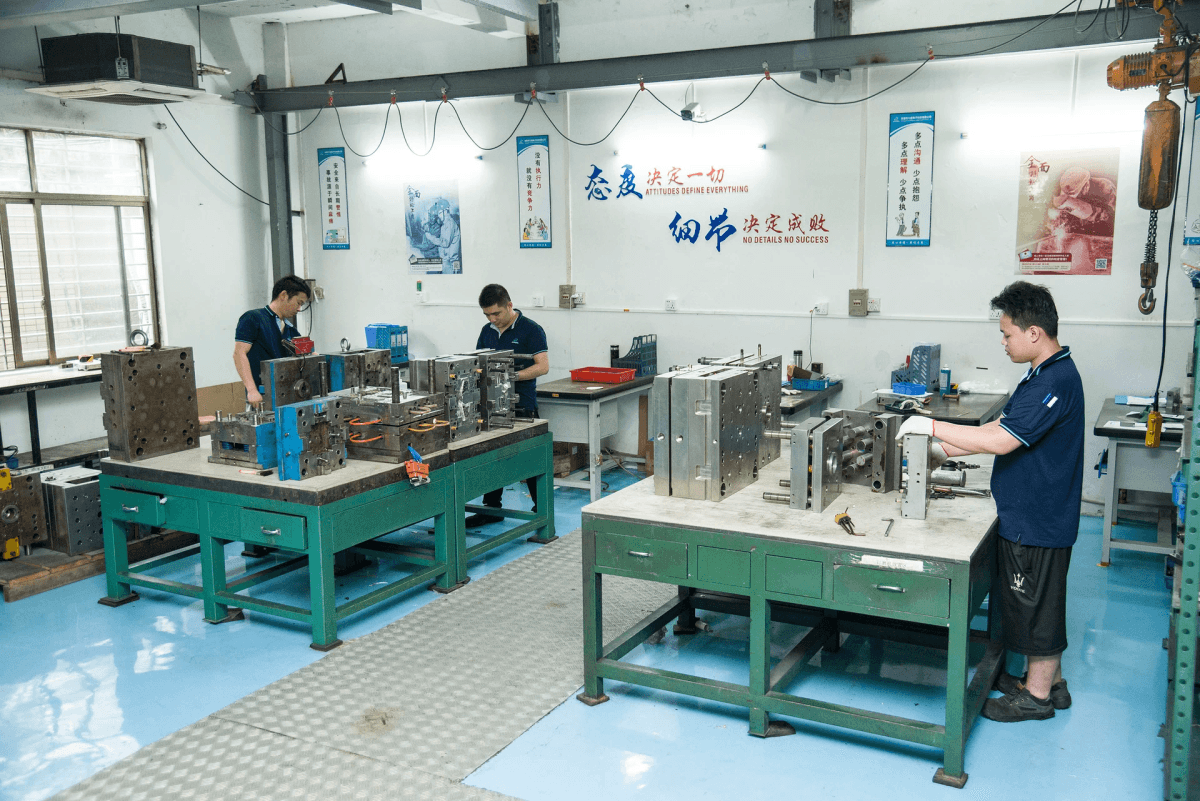

Case Studies: Successful Weld Line Management

To illustrate effective strategies for managing weld lines in injection molding, let’s look at a couple of real-world case studies showcasing successful interventions by industry leaders. In one instance, a manufacturer faced significant quality control issues due to frequent weld line formation on their consumer electronics casing parts made from specific plastic for molding applications. By redesigning their mold with advanced venting techniques and optimizing gate placement based on flow simulations provided by Baoyuan experts, they reduced defects by over 70%.

In another case involving automotive parts production using complex geometries with multiple gates, engineers discovered that adjusting cooling times led to substantial improvements in product integrity at weld points—resulting in fewer rejections during inspection phases. Thanks to innovative solutions tailored specifically for their needs within plastic injection molding mold setups, both companies not only minimized waste but also enhanced overall product performance significantly.

Conclusion

In wrapping up our exploration of weld lines in injection molding, it’s essential to recognize the primary culprits behind their formation. Factors such as material selection, mold design, and processing parameters play significant roles in the occurrence of these imperfections. Understanding these causes can empower manufacturers to make informed decisions that enhance product quality and reduce defects.

Summary of Key Causes of Weld Lines

Weld lines in injection molding primarily arise from the flow characteristics of the injected material and how it interacts within the mold cavity. Polymer type, viscosity, and flow rate are crucial elements that influence whether weld lines will form during the injection process. Additionally, poor mold design—such as inadequate gate placement or insufficient venting—can exacerbate these issues, leading to unsightly weld lines on finished products.

Tips for Preventing Weld Lines in Injection Molding

To effectively prevent weld lines in injection molding, start by selecting appropriate injection moldable plastics that offer optimal flow properties for your specific application. Adjusting temperature settings and pressure levels can also significantly impact how well materials fill the mold cavity without creating unwanted seams or marks. Lastly, thoughtful mold design for injection molding—considering factors like gate location and venting—can minimize the risk of weld line formation altogether.

The Future of Weld Line Management Innovations

Looking ahead, innovations in plastic for molding are set to revolutionize how we address weld lines in injection molding processes. Advances in material science may lead to new polymers with enhanced flow characteristics that virtually eliminate weld line issues altogether. Moreover, smart manufacturing technologies will likely integrate real-time monitoring systems to adjust parameters dynamically during production, ensuring consistent quality while minimizing defects like weld lines.