Introduction

Water injection molding is revolutionizing the way we think about plastic manufacturing, combining efficiency with precision in ways that traditional methods simply can't match. This innovative technique utilizes water as a medium to create hollow parts, allowing for lighter products and reduced material costs. As industries strive for sustainability and enhanced performance, understanding the nuances of water-assisted techniques becomes increasingly vital.

Understanding the Basics of Water Injection Molding

At its core, water injection molding is an advanced form of plastic injection molding that employs high-pressure water to fill a mold cavity, forming complex shapes with remarkable accuracy. Unlike conventional mould injection moulding processes that rely solely on molten plastic, this method introduces water into the mix, enabling the creation of intricate designs while minimizing waste. By utilizing injection moldable plastics in conjunction with this technology, manufacturers can produce components that are not only lightweight but also structurally sound.

The Advantages of Water-Assisted Techniques

The benefits of water-assisted techniques are manifold; foremost among them is the significant reduction in cycle times compared to traditional methods. With quicker cooling rates and enhanced flow characteristics, manufacturers can achieve faster production cycles without sacrificing quality or detail in their mold plastic injection projects. Additionally, improved surface finishes result from reduced shrinkage and warping during cooling—an essential factor for industries demanding high aesthetic standards.

Applications Across Various Industries

Water injection molding finds its place across a diverse range of sectors—from automotive to consumer goods and medical devices—highlighting its versatility and adaptability. In automotive manufacturing, for instance, it allows for lightweight components that contribute to fuel efficiency without compromising safety or performance standards. Similarly, in consumer goods production and medical device fabrication, the ability to create intricate designs with precise tolerances makes this technique invaluable for meeting stringent industry requirements.

What is Water-Assisted Injection Molding?

Water-assisted injection molding is a revolutionary technique that enhances the traditional plastic injection molding process. By utilizing water as a means to create hollow sections in molded parts, this method offers significant advantages over conventional mould injection moulding. It’s an innovative approach that not only improves efficiency but also optimizes the quality of the final product.

Definition and Overview

At its core, water injection molding involves injecting water into a molten plastic material within the mold cavity. This process allows for the creation of complex shapes with reduced material usage while maintaining structural integrity. In essence, it transforms standard plastic injection molding into a more versatile and effective manufacturing solution.

In comparison to conventional methods, this technique can significantly reduce cycle times and enhance design flexibility. By leveraging the properties of water, manufacturers can achieve intricate designs that might be challenging or impossible with traditional moulding techniques. The result is a more efficient production line capable of delivering high-quality components across various industries.

How It Differs from Traditional Methods

The primary difference between water-assisted injection molding and traditional methods lies in how cooling occurs within the mold cavity. In standard plastic injection molding, cooling is typically achieved through air or coolant channels; however, in water injection molding, water acts as both a cooling medium and an internal pressure source during solidification. This dual function not only accelerates cooling rates but also minimizes warping and sink marks on molded parts.

Moreover, while traditional methods often require additional steps for achieving hollow structures—such as using inserts or cores—water injection simplifies this by creating voids directly during the molding process itself. This leads to lighter parts without compromising strength or durability, making it an attractive alternative for manufacturers seeking to optimize their designs without incurring extra costs related to tooling changes.

The Science Behind Water Injection Molding

The science behind water injection molding hinges on fluid dynamics and thermodynamics principles governing heat transfer and pressure management within molds. When molten plastic is injected into the mold cavity alongside pressurized water, it forms an outer shell as it cools while leaving a hollow core inside—a key advantage for producing lightweight components efficiently.

This process requires precise control over temperature and pressure conditions to ensure optimal results; too much pressure could lead to defects like short shots or incomplete fills in moldable plastics, while insufficient pressure may cause structural weaknesses in finished products. Thus, understanding these scientific principles allows engineers to fine-tune their processes for maximum efficiency and quality output in each batch produced.

Advantages of Water Injection Molding

Water injection molding offers a host of benefits that set it apart from traditional mould injection moulding techniques. This innovative process not only streamlines production but also enhances the quality and versatility of plastic products. Below, we delve into three standout advantages: reduced cycle times, enhanced design flexibility, and improved surface finish.

Reduced Cycle Times

One of the most significant advantages of water injection molding is its ability to drastically reduce cycle times. By utilizing water as a cooling medium during the injection process, manufacturers can achieve faster solidification of injected materials compared to conventional methods. This means that plastic injection molding machines can produce more parts in less time, increasing overall productivity and efficiency in manufacturing.

Additionally, reduced cycle times lead to lower energy consumption and operational costs—an appealing prospect for businesses looking to optimize their processes. With quicker turnaround times on projects, companies can respond rapidly to market demands without sacrificing quality or performance in their mold plastic injection operations. Ultimately, this boost in efficiency translates into higher profits and a competitive edge in the marketplace.

Enhanced Design Flexibility

Water-assisted techniques also provide remarkable design flexibility that traditional injection molding may struggle to accommodate. The ability to create complex geometries with intricate details opens up new possibilities for product innovation across various industries. Designers can push boundaries without worrying about limitations imposed by conventional moulding processes.

Moreover, this flexibility allows for the use of lightweight materials while maintaining structural integrity—an essential consideration in fields such as automotive manufacturing where weight reduction is crucial for fuel efficiency and performance. As a result, water injection molding enables manufacturers to explore creative designs that were previously deemed unfeasible with standard plastic injection molding methods.

Improved Surface Finish

Another compelling advantage is the superior surface finish achieved through water injection molding processes. The introduction of water during cooling helps eliminate defects like sink marks or voids often seen in traditional moulding techniques. This results in products with smoother surfaces that require minimal post-processing work.

In industries where aesthetics matter—such as consumer goods or medical devices—a flawless surface finish can significantly impact product appeal and functionality. Furthermore, achieving high-quality finishes reduces the need for additional coatings or treatments, saving both time and resources during production cycles involving plastic injection molding molds.

The Water Injection Molding Process

Water injection molding is a sophisticated technique that enhances traditional plastic injection molding methods. By utilizing water as a cooling agent, this process allows for more efficient production cycles and improved part quality. Let’s dive into the nitty-gritty of how this innovative method unfolds.

Step-by-Step Breakdown

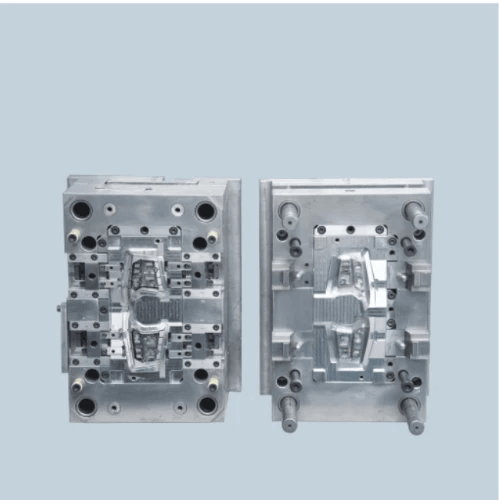

The water injection molding process begins with the preparation of the injection machine mold, where the chosen injection moldable plastics are loaded into the system. Once heated to a specific temperature, these plastics are injected into a pre-designed cavity within the mold. After the initial cooling phase, water is injected into the core of the molded part to solidify it further, allowing for rapid cycle times and precise control over part dimensions.

Following this step, excess pressure is released, and any remaining water is expelled from the mold cavity before it opens. This two-phase cooling process not only speeds up production but also enhances surface finish quality by minimizing warping or distortion in complex geometries typical in mould injection moulding applications. Finally, once ejected from the plastic injection molding mold, parts are ready for further processing or assembly.

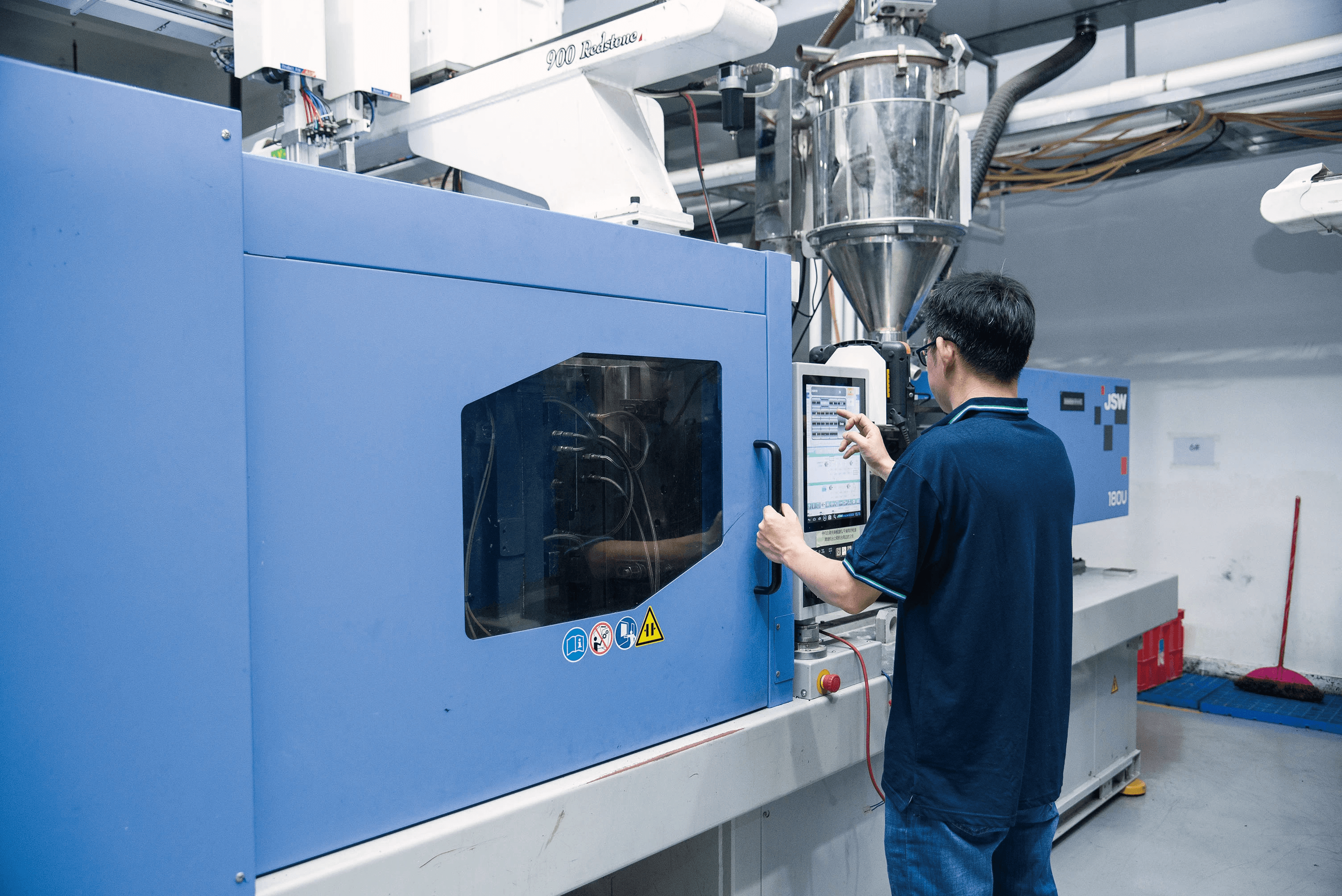

Key Equipment and Technologies

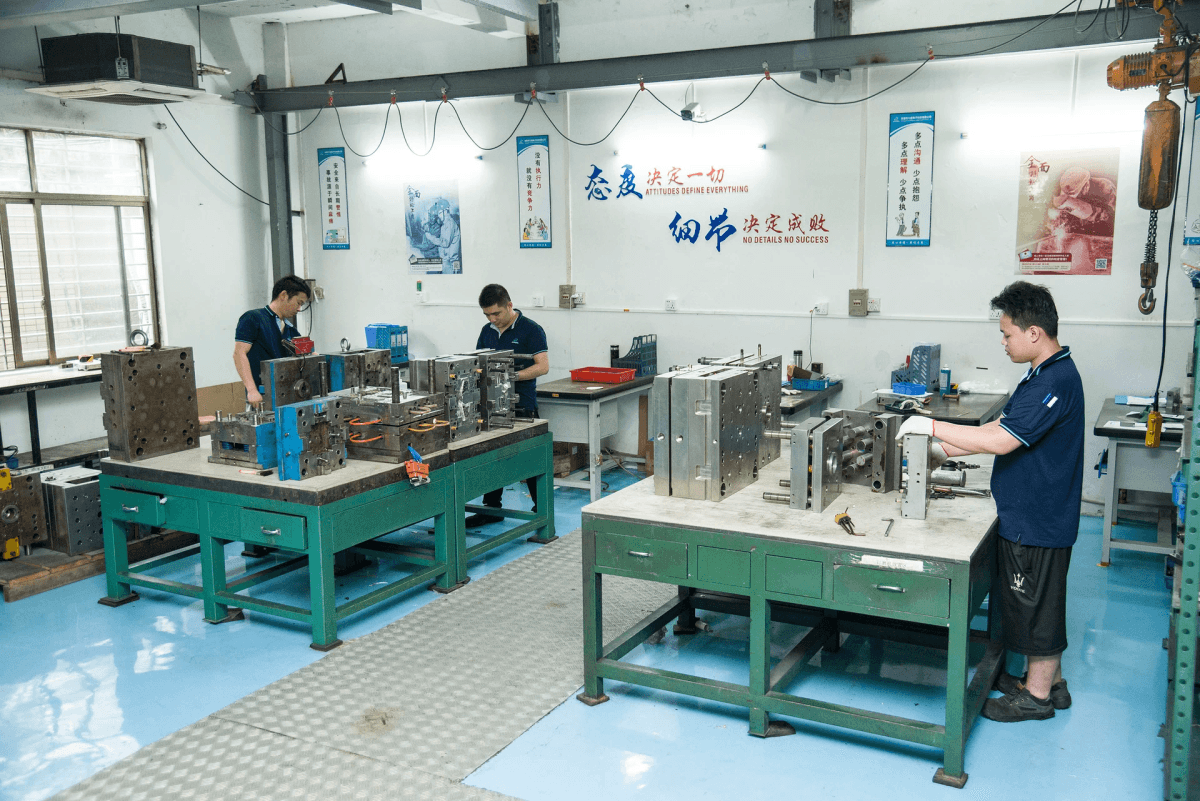

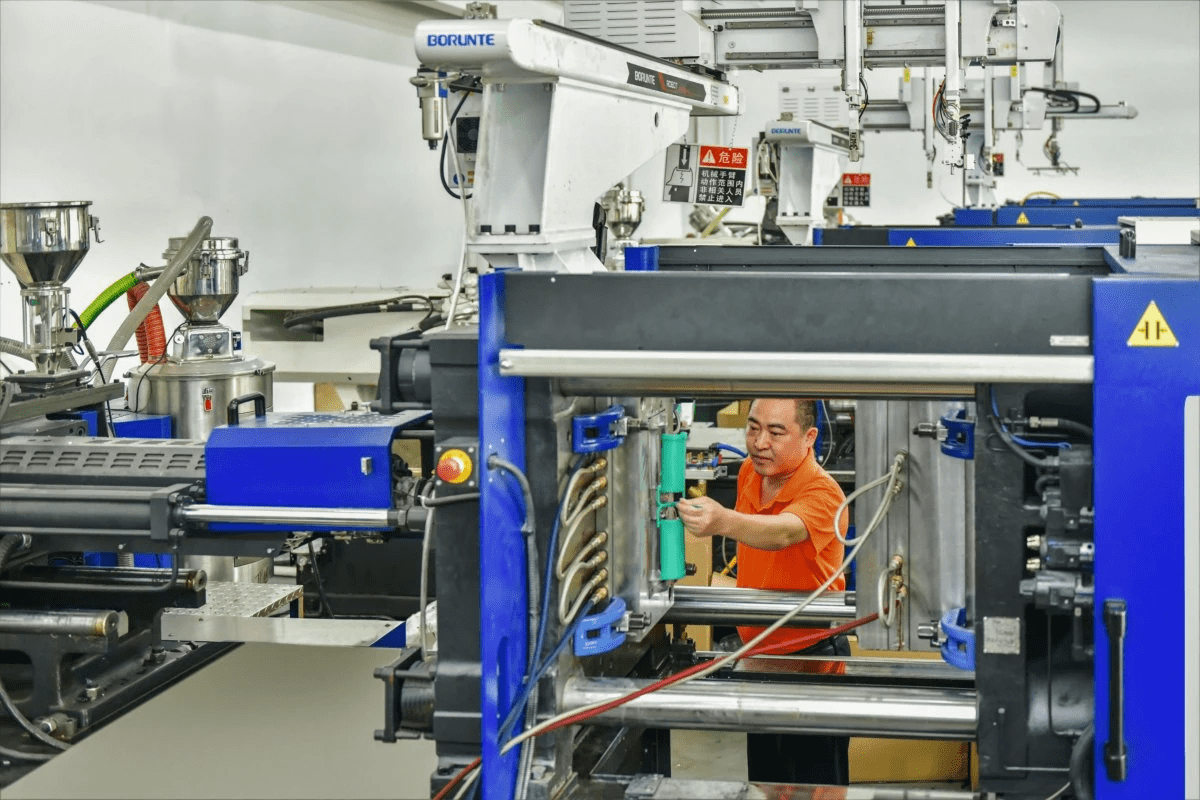

A successful water injection molding operation requires specialized equipment tailored to handle both traditional plastic materials and water-based processes. Central to this setup is an advanced injection machine equipped with a dual-channel system that manages both plastic feed and water injections seamlessly. Additionally, precise temperature control units ensure that both plastic and water remain at optimal conditions throughout their respective phases.

Other vital components include specialized molds designed to withstand high pressure while allowing for effective drainage of excess water post-injection. Sensors play an essential role in monitoring real-time conditions during each cycle—ensuring consistent quality across batches of produced parts made from various types of injection moldable plastics. Together, these technologies form an ecosystem that maximizes efficiency and product integrity in every run.

Role of Baoyuan in the Process

Baoyuan stands out as a key player in revolutionizing the water injection molding landscape through innovative solutions tailored for modern manufacturing needs. With extensive expertise in designing state-of-the-art equipment specifically for mould injection moulding processes, Baoyuan helps businesses transition smoothly from conventional methods to more advanced techniques like water-assisted systems. Their commitment to providing comprehensive support—from initial design consultations to ongoing maintenance—ensures that clients optimize their production capabilities effectively.

Moreover, Baoyuan's cutting-edge technology integrates seamlessly with existing plastic injection molding systems while enhancing overall performance metrics such as cycle time reduction and surface finish improvement across diverse applications—from automotive components to consumer goods manufacturing. By partnering with Baoyuan, companies can leverage their knowledge base and technological advancements to stay ahead in an increasingly competitive market focused on sustainability and efficiency.

Applications of Water-Assisted Injection Molding

Water-assisted injection molding is making waves across various industries, proving itself as a game changer in terms of efficiency and design potential. By leveraging the unique properties of water, manufacturers can produce complex parts with less waste and shorter cycle times. Let’s dive into some specific applications where this innovative technique shines.

Automotive Industry Uses

The automotive industry is one of the most significant beneficiaries of water injection molding technology. With the constant demand for lightweight yet durable components, manufacturers are turning to water-assisted techniques to create intricate parts for vehicles. This method allows for the production of large, hollow sections, like door panels and dashboards, that reduce weight without compromising structural integrity.

In addition to weight reduction, plastic injection molding with water assistance enables automotive designers to explore new shapes and forms that were previously challenging or impossible to achieve. Enhanced surface finishes from this process also mean fewer secondary operations are needed—saving both time and money in production lines. As electric vehicles gain traction, the need for high-performance materials in battery housings further emphasizes the role of water injection molding in meeting industry demands.

Consumer Goods Manufacturing

Consumer goods manufacturing has also seen a significant shift towards adopting water-assisted techniques due to their versatility and efficiency. From household items like containers and kitchenware to electronic gadgets, this method allows manufacturers to create aesthetically pleasing products with smooth surfaces while minimizing material waste. The ability to mold complex shapes means that brands can offer more innovative designs that appeal directly to consumer preferences.

Moreover, using injection moldable plastics with water assistance can drastically shorten production cycles compared to traditional methods. This speed not only helps meet market demands but also reduces costs associated with inventory management and storage. As competition heats up in consumer markets, companies that harness water injection molding will likely gain an edge through faster turnaround times and superior product quality.

Medical Device Production

In the realm of medical device production, precision is paramount—and that's where water injection molding truly excels. It allows for the creation of intricate components used in devices such as syringes, surgical instruments, and diagnostic equipment with exceptional accuracy and cleanliness standards required by the industry. The ability to produce complex geometries while maintaining high tolerances makes it an attractive option for manufacturers focused on innovation in healthcare.

Furthermore, using plastic injection molding techniques infused with water can help minimize contamination risks during production processes—a critical factor when dealing with medical applications where sterility is essential. The enhanced surface finish achieved through this method not only improves aesthetics but also contributes positively toward cleaning protocols post-production. As healthcare continues evolving rapidly towards advanced technologies, embracing efficient manufacturing methods like water-assisted techniques will be crucial.

Challenges and Considerations

While water injection molding presents numerous benefits, it’s not without its hurdles. Understanding these challenges is crucial for manufacturers considering this innovative technique. Let’s dive into the common limitations, cost factors, and environmental considerations surrounding water-assisted injection molding.

Common Limitations of Water Injection Molding

Water injection molding, despite its advantages, comes with some notable limitations that can impact its adoption. One primary concern is the complexity of the process; integrating water into traditional plastic injection molding requires specialized equipment and expertise that may not be readily available in all facilities. Moreover, certain materials may not be compatible with this method, limiting the range of injection moldable plastics that can be effectively utilized.

Another limitation lies in the potential for increased cycle time for specific designs or materials compared to conventional methods. While water-assisted techniques generally reduce cycle times, intricate designs may require additional adjustments to achieve optimal results. Additionally, quality control becomes more critical as variations in moisture levels can affect the final product's integrity and performance.

Finally, there are regulatory challenges associated with using water in industrial processes—ensuring compliance with safety standards can complicate implementation for manufacturers new to this technology. As such, thorough research and planning are essential before committing to a shift towards water injection molding.

Cost Factors and Economic Viability

When evaluating the economic viability of water-assisted techniques versus traditional mould injection moulding methods, cost is a significant factor to consider. Initial investments in specialized equipment and training can be steep; however, these costs must be weighed against long-term savings from reduced cycle times and improved production efficiency. For many businesses looking to optimize their operations, understanding these trade-offs becomes vital.

Moreover, while operational costs may decrease due to faster production rates when using plastic injection molding molds designed for water-assisted techniques, maintenance expenses could rise due to more complex machinery involved in this process. Manufacturers must also account for potential downtime related to employee training or equipment upgrades when calculating overall costs associated with transitioning to a new system.

Ultimately, companies need a comprehensive financial analysis that considers both short-term expenditures and long-term returns on investment when deciding whether or not to adopt water injection molding methods into their production lines.

Environmental Considerations

In today’s eco-conscious world, environmental considerations play a pivotal role in manufacturing decisions—including those involving water injection molding processes. While utilizing water as a medium reduces reliance on traditional solvents or chemicals often used in mould plastic injection operations—thereby minimizing harmful emissions—it also raises questions about resource management and waste disposal practices related to excess water usage.

Furthermore, manufacturers must consider how changes in their production processes align with sustainability goals set by consumers or regulatory bodies alike. Adopting environmentally friendly practices is no longer just an option but rather an expectation within many industries; thus ensuring that systems employed remain compliant with environmental regulations is paramount.

Lastly—and perhaps most importantly—the perception of sustainability among customers can significantly influence market competitiveness. Companies embracing innovative technologies like water-assisted techniques should highlight these efforts as part of their broader commitment towards reducing environmental impact while enhancing product quality through advanced plastic injection molding methods.

Conclusion

Water injection molding has emerged as a revolutionary technique in the world of plastic manufacturing, offering numerous benefits over traditional methods. By utilizing water-assisted techniques, manufacturers can achieve faster cycle times, enhanced design flexibility, and improved surface finishes. As industries continue to evolve, the adoption of water injection molding is likely to grow, making it a key player in modern production processes.

Recap of Water Injection Molding Benefits

The advantages of water injection molding are hard to ignore. This innovative approach leads to reduced cycle times, enabling quicker production while maintaining high-quality standards in the final product. Additionally, the flexibility offered by this method allows for complex designs that were previously challenging with standard mould injection moulding techniques.

Moreover, improved surface finishes result from the cooling effects of water during the process, which can significantly enhance the aesthetic appeal of plastic injection molding products. With its ability to handle various injection moldable plastics efficiently, water injection molding stands out as a preferred choice for many manufacturers looking to optimize their processes and outputs.

Future Trends in the Industry

Looking ahead, several trends are expected to shape the future landscape of water injection molding and its applications across industries. The integration of advanced technologies such as automation and smart manufacturing will likely enhance efficiency further while reducing operational costs associated with traditional plastic injection molding methods. Additionally, sustainability will play a crucial role; as environmental concerns grow, manufacturers may increasingly turn toward eco-friendly practices within their production lines.

The demand for lightweight components in sectors like automotive and aerospace will also drive innovation in water-assisted techniques. These trends suggest that companies investing in modernizing their processes through water injection molding will not only meet current market demands but also position themselves competitively for future challenges.

Choosing the Right Partner for Implementation

Selecting an appropriate partner for implementing water injection molding is vital for success in this evolving landscape. Look for companies that have extensive experience with both traditional and innovative techniques like mold plastic injection and possess a deep understanding of various types of injection machine molds available on the market today. A partner that prioritizes collaboration can help tailor solutions that meet specific needs while maximizing efficiency.

Furthermore, consider partners who are committed to ongoing research and development within this field; staying updated on advancements ensures your operations benefit from cutting-edge technology and practices in plastic injection molding mold design and application. Ultimately, choosing a knowledgeable ally will pave your way toward harnessing all advantages offered by water-assisted techniques effectively.