Introduction

In the dynamic world of manufacturing, high-heat resins have carved out a niche for themselves, offering unparalleled performance in extreme environments. Understanding how to effectively utilize these materials is crucial for engineers and designers alike. This guide will explore key design considerations for high-heat resins, provide injection molding process improvement tips, and delve into essential techniques for working with exotic resins.

Key Design Considerations for High-Heat Resins

Understanding how these factors influence your material choice is vital in achieving optimal performance in demanding applications. By keeping these considerations front and center during the design phase, you can avoid common pitfalls that might derail your injection molding process.

Injection Molding Process Improvement Tips

So, how can I improve my injection molding process? The answer lies in refining each step of the operation while also being mindful of material selection and equipment capabilities. Implementing targeted injection molding tips—such as optimizing temperature settings and adjusting cycle times—can lead to significant enhancements in both efficiency and product quality.

Essential Techniques for Exotic Resins

Working with exotic resins requires a unique set of skills and knowledge; after all, not all materials behave the same way under pressure! Familiarizing yourself with specialized techniques is essential to navigate challenges that arise during processing. From understanding the rule of thumb for injection molding to mastering the five steps of injection molding, honing your expertise will help you achieve superior results when dealing with these advanced materials.

Understanding High-Heat Resins

High-heat resins have become a staple in industries requiring materials that can withstand extreme temperatures without compromising structural integrity. These advanced polymers are designed to perform in demanding environments, making them ideal for applications ranging from aerospace to automotive components. Understanding the properties and applications of high-heat resins is crucial for optimizing your injection molding process.

Popular High-Heat Resins in the Market

Each of these materials boasts impressive thermal stability, chemical resistance, and mechanical strength, making them top choices for specialized applications. If you're pondering how you can improve your injection molding process with these resins, consider their unique characteristics to ensure optimal performance.

PEEK is particularly favored for its outstanding thermal properties and is often used in medical devices and aerospace parts. PPS offers excellent dimensional stability under heat, which makes it suitable for electrical components. Meanwhile, Polyimides shine in applications requiring extreme heat resistance and flexibility—perfect for situations where traditional materials might fail.

Thermal Properties Impacting Design

The thermal properties of high-heat resins play a pivotal role in design considerations when it comes to injection molding. Key factors such as glass transition temperature (Tg) and melting temperature (Tm) dictate how these materials behave under different conditions. To answer the question “What is the rule of thumb for injection molding?” remember that understanding these thermal thresholds will help you tailor your designs accordingly.

For instance, if you're working with PEEK, knowing its Tg allows you to set appropriate processing temperatures during injection molding; this ensures better flow characteristics while minimizing defects like warping or shrinkage. Additionally, understanding how thermal expansion affects part dimensions can lead you toward more stable designs that withstand operational stresses without faltering.

Incorporating effective cooling strategies based on these properties can also enhance cycle times—a crucial aspect if you're looking at techniques for reducing cycle time during production runs.

Applications and Industry Uses

High-heat resins find their niche across various industries due to their superior performance under stress and temperature extremes. In aerospace engineering, PEEK is often utilized for components like brackets or housings that require both lightweight construction and durability against harsh environmental conditions. Similarly, automotive manufacturers leverage PPS for fuel system components thanks to its excellent resistance against fuels and oils.

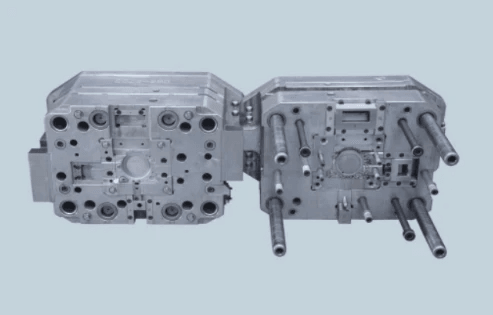

Furthermore, electronics manufacturers are increasingly turning toward polyimides because they provide not only thermal stability but also electrical insulation—vital elements in circuit boards or connectors subjected to high temperatures during operation. When considering what are three key design considerations for injection mould design using these exotic materials: think about material choice based on application needs, geometric complexity versus manufacturability principles, and ensuring adequate cooling channels within molds.

To sum up this section on understanding high-heat resins: knowing which materials suit your application best will empower you with effective injection molding tips that streamline production processes while maintaining quality standards across the board.

Injection Molding Techniques for Exotic Materials

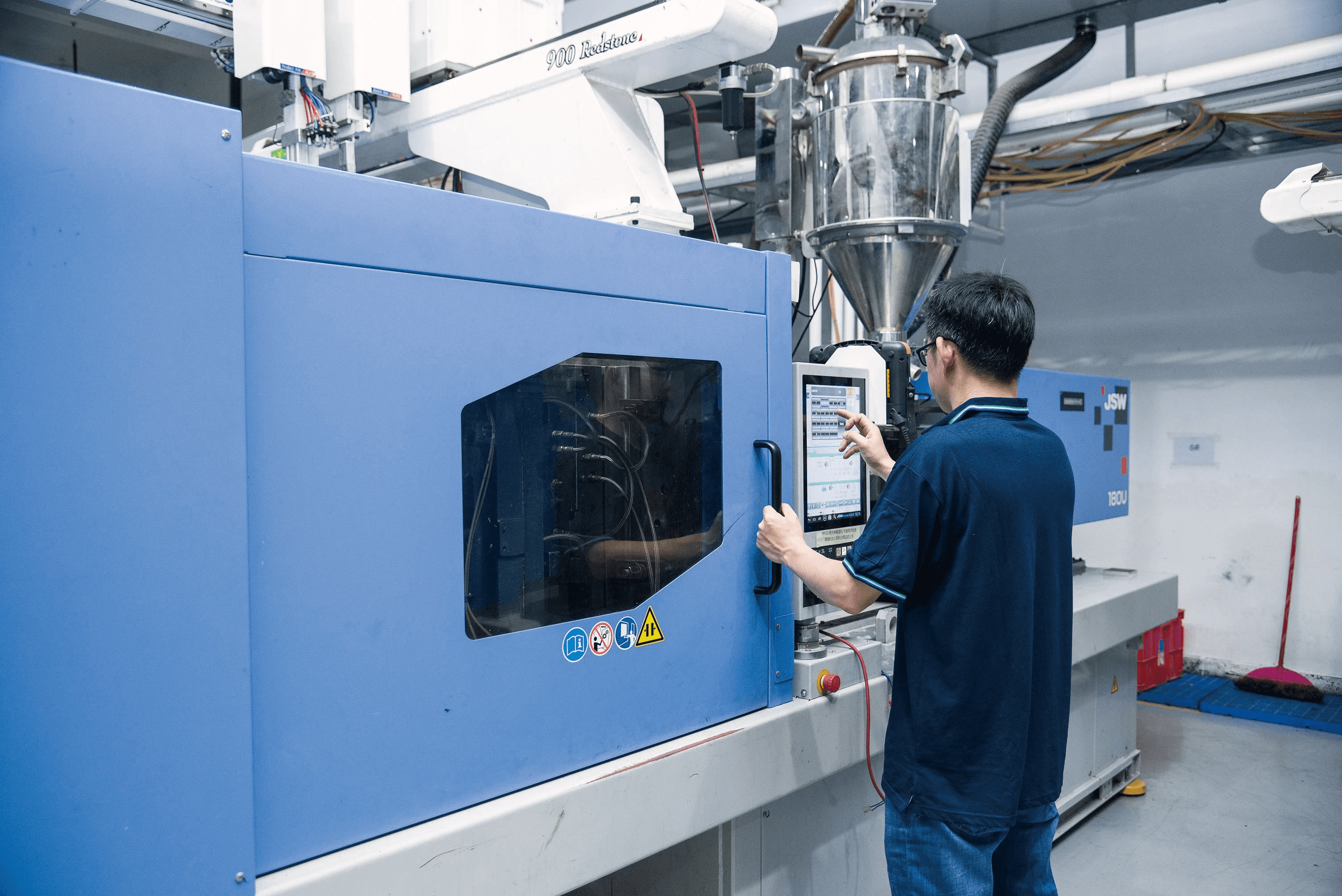

Specialized Molding Equipment Recommendations

To successfully mold exotic materials, investing in specialized equipment is crucial. High-performance injection molding machines equipped with precise temperature control and advanced screw designs are essential for handling high-heat resins effectively. Additionally, using molds made from durable materials that can withstand elevated temperatures ensures longevity and consistent quality in your parts.

One of the key injection molding tips is to consider using a closed-loop cooling system for better thermal management during processing. This helps maintain optimal temperatures, preventing material degradation and ensuring uniform flow characteristics. Remember, the right equipment isn’t just a luxury; it’s a necessity when you're asking yourself how you can improve your injection molding process!

Challenges in Processing Exotic Resins

Processing exotic resins comes with its fair share of challenges that can throw a wrench in your production plans. These materials often exhibit high viscosity and require specific temperature profiles that differ significantly from conventional thermoplastics. Additionally, their tendency to absorb moisture can lead to defects if not properly managed during processing.

Another common issue is warping or dimensional instability due to thermal expansion differences between the resin and mold materials—this directly ties back to the rule of thumb for injection molding: always account for material behavior under heat! Understanding these challenges is vital as you navigate through complex projects involving exotic resins.

Best Practices to Overcome Common Issues

To tackle the obstacles presented by exotic materials, implementing best practices is key! Start by conducting thorough pre-processing checks on moisture content; utilizing drying systems can mitigate absorption issues effectively. Moreover, closely monitoring melt temperature and pressure will help maintain consistency throughout the injection cycle.

Incorporating feedback loops into your process allows real-time adjustments based on observed performance—this ties back nicely into those five steps of injection molding: filling, packing, cooling, ejection, and post-processing! Lastly, collaborating with industry experts can provide invaluable insights into overcoming specific challenges unique to your project.

Design Considerations for Injection Molding

The Rule of Thumb for Optimal Design

What is the rule of thumb for injection molding? Well, it's all about simplicity and functionality! A good starting point is to aim for uniform wall thickness throughout the part, as this minimizes stress concentrations and prevents warping during cooling. Additionally, incorporating rounded corners instead of sharp edges can improve flow dynamics and reduce potential weak points in your design.

Another vital aspect is ensuring adequate draft angles on vertical surfaces to facilitate part ejection without damaging the mold or the part itself. Remember, each degree counts! Following these injection molding tips not only enhances manufacturability but also contributes to a smoother production process overall.

Features to Enhance Part Stability

To ensure that your molded parts remain stable under various conditions, consider integrating features that bolster their structural integrity. For instance, ribbing can be an effective way to provide additional strength without significantly increasing material usage or weight. Strategically placing ribs along load-bearing areas helps distribute stress evenly across the part.

Another feature worth considering is adding bosses or inserts where mechanical fasteners will be used; this enhances stability while also simplifying assembly processes later on. It's essential to think ahead: How can I improve my injection molding process? By incorporating these thoughtful design features right from the start!

Design for Manufacturability Principles

Designing for manufacturability (DFM) is an approach that emphasizes creating parts with ease of manufacturing in mind—essentially making life easier for everyone involved! Key principles include minimizing complex geometries and avoiding undercuts whenever possible; both strategies help reduce mold costs and lead times significantly.

Moreover, consider how material selection impacts your design choices; some materials may require different tolerances or processing techniques than others, especially when dealing with high-heat resins or exotic materials. By adhering to DFM principles, you not only optimize your designs but also align them with industry standards—making it easier for manufacturers to produce high-quality components consistently.

Streamlining the Injection Molding Process

Streamlining the injection molding process is essential for enhancing efficiency, reducing costs, and improving product quality. By focusing on key steps and considerations, manufacturers can optimize their operations and achieve better results. This section will explore the five fundamental steps of injection molding, highlight the importance of material selection, and provide actionable techniques for reducing cycle time.

Five Steps of Injection Molding Explained

The injection molding process can be broken down into five essential steps: clamping, injection, cooling, ejection, and finishing. First up is clamping; this step involves securely closing the mold to withstand the pressure during injection. Next comes injection itself—this is where melted resin is injected into the mold cavity under high pressure to form your desired shape.

Once the material has been injected into the mold, it’s time for cooling. This critical phase allows the resin to solidify before ejection; proper cooling ensures that parts maintain their shape and dimensional accuracy. After cooling comes ejection; this step involves opening the mold and removing the finished part without damaging it. Finally, finishing touches may include trimming excess material or surface treatment to enhance aesthetics or performance.

Understanding these five steps of injection molding is crucial when considering how to improve your injection molding process. Each phase plays a vital role in producing high-quality parts efficiently.

Importance of Material Selection

Material selection is one of those golden rules in manufacturing that cannot be overlooked when discussing injection molding tips. The choice of resin impacts not only part performance but also processing conditions like temperature and pressure during each stage of production. Selecting a high-heat resin suitable for your application can lead to improved durability while ensuring compatibility with existing equipment.

Choosing materials wisely also affects cycle times—certain resins cool faster than others which can significantly reduce overall production time. Additionally, understanding thermal properties helps in predicting how materials will behave under stress or heat exposure in real-world applications. So when asking yourself How can I improve my injection molding process?, remember that starting with appropriate material selection sets a solid foundation for success.

In summary, prioritizing correct material choices ensures optimal performance while aligning with industry standards—leading you towards efficient manufacturing practices.

Techniques for Reducing Cycle Time

Reducing cycle time in injection molding isn’t just about speeding things up; it's about optimizing every aspect of production without sacrificing quality! One effective technique involves adjusting processing parameters such as melt temperature and mold temperature; finding that sweet spot can enhance flow characteristics while minimizing defects like warping or short shots.

Another approach includes implementing advanced technologies such as hot runner systems which help maintain consistent temperatures throughout the process—this not only reduces waste but also leads to faster cycle times by eliminating additional cooling phases associated with traditional cold runners! Additionally, regular maintenance checks on machinery ensure everything runs smoothly without unexpected downtimes that could derail productivity goals.

Lastly—and perhaps most importantly—training staff on best practices related to machine operation plays a pivotal role in achieving efficiency gains over time! When everyone understands what the rule of thumb for injection molding entails along with common pitfalls to avoid (like improper venting), it fosters an environment where continuous improvement thrives!

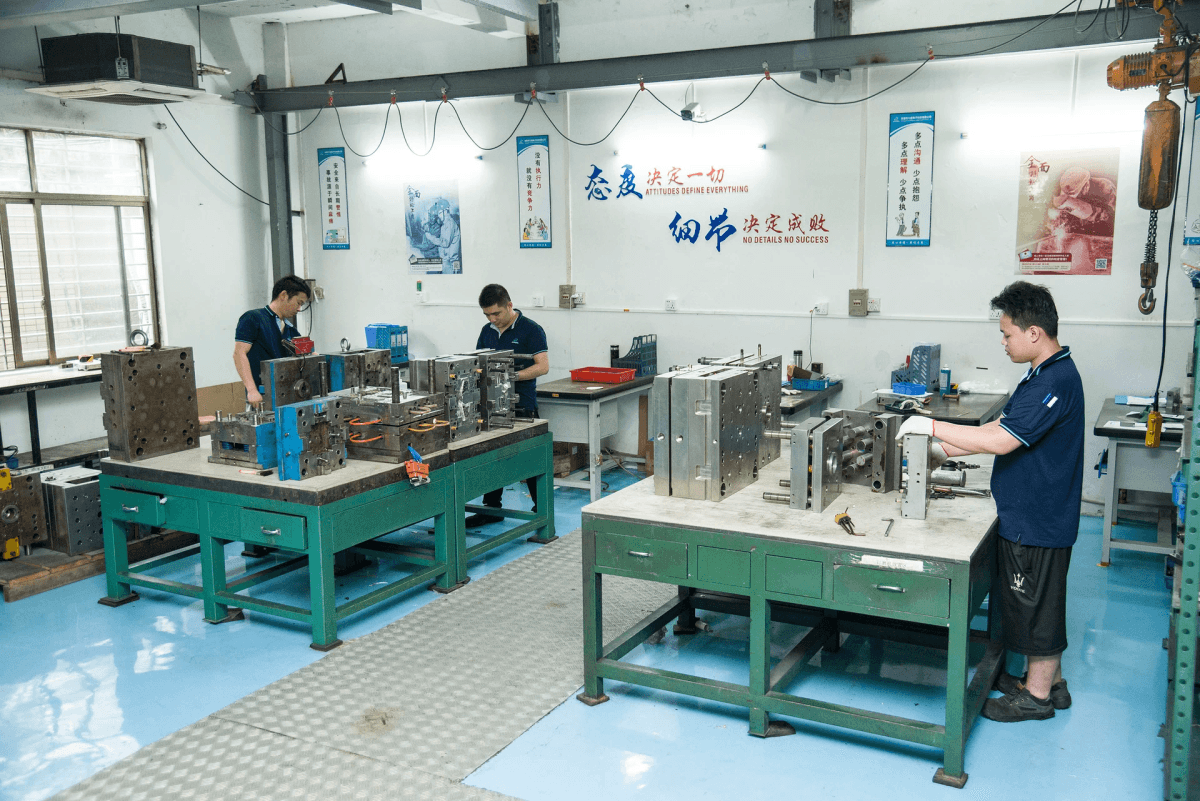

Collaboration with Experts like Baoyuan

When it comes to navigating the complexities of high-heat resins and exotic materials, collaboration with industry experts like Baoyuan can be a game changer. Their extensive experience provides valuable insights that can enhance your injection molding process significantly. By tapping into their knowledge, you’ll not only optimize your designs but also streamline production, making your operations more efficient.

Leveraging Baoyuan’s Industry Expertise

Baoyuan's team brings a wealth of knowledge in injection molding tips that can help you tackle specific challenges associated with high-heat and exotic resins. They understand the nuances of these materials and how they behave under different conditions, allowing them to offer tailored solutions for your projects. Whether you're asking How can I improve my injection molding process? or looking for advice on material selection, their expertise will guide you toward success.

Their insights extend beyond just material properties; they encompass the entire injection molding process as well. By collaborating with Baoyuan, you'll gain access to industry best practices that can improve both efficiency and product quality. This partnership allows you to leverage their experience while focusing on what you do best—designing innovative products.

Quality Assurance Best Practices

Quality assurance is paramount in the injection molding industry, especially when working with high-heat resins or exotic materials that require precise handling. Baoyuan emphasizes implementing robust quality control measures throughout the production cycle to ensure consistency and reliability in every batch produced. This means identifying potential issues early on and employing strategies that adhere to established standards.

Incorporating these quality assurance best practices will not only enhance product performance but also minimize waste—an essential aspect of any efficient manufacturing process. By understanding What is the rule of thumb for injection molding?, you’ll find that maintaining rigorous quality checks is part of ensuring optimal design outcomes as well as operational efficiency.

Additionally, Baoyuan's commitment to continuous improvement means they are always seeking new ways to refine processes and elevate product standards further. Regular training sessions and workshops keep teams updated on the latest techniques in quality management, ensuring that everyone involved understands how crucial their role is in achieving excellence.

Software Solutions for Enhanced Design

In today's digital age, leveraging advanced software solutions is critical for optimizing your injection molding designs—especially when dealing with complex materials like high-heat resins or exotic compounds. Baoyuan utilizes cutting-edge software tools that facilitate simulation and analysis during the design phase, helping identify potential issues before they become costly problems down the line.

These software solutions allow designers to visualize their projects thoroughly by providing detailed insights into flow dynamics and thermal behavior during processing—key elements when answering What are three key design considerations for injection mould design? With such tools at your disposal, making informed decisions becomes much easier.

Moreover, integrating these technologies into your workflow not only enhances productivity but also fosters collaboration among team members across different departments—from engineering to production management. As a result, everyone benefits from shared knowledge while streamlining processes based on real-time data analytics tailored specifically for improving injection molding processes.

Conclusion

In wrapping up our exploration of high-heat resins and the intricacies of injection molding, it's clear that innovation is at the heart of optimizing these processes. The strategies discussed not only enhance performance but also ensure that products meet the rigorous demands of various industries. By implementing these innovative approaches, manufacturers can push the boundaries of what’s possible in high-heat applications.

Innovative Strategies for High-Heat Applications

To truly excel in high-heat applications, it’s essential to adopt cutting-edge materials and techniques tailored for resilience under extreme conditions. One effective strategy is to utilize advanced cooling systems in your injection molding process; this can significantly reduce cycle times while maintaining part integrity. Additionally, embracing simulation software allows designers to visualize potential issues before they arise, streamlining production and enhancing overall efficiency.

Key Takeaways on Molding Exotic Resins

When it comes to molding exotic resins, understanding their unique properties is paramount. Remember the rule of thumb for injection molding: always prioritize material compatibility with your design to avoid costly errors later on! Furthermore, familiarize yourself with the five steps of injection molding—material selection, heating, injecting, cooling, and ejection—as these are crucial for achieving optimal results every time.

Final Thoughts on Optimizing Molding Processes

Optimizing your injection molding process isn’t just a one-time task; it’s an ongoing journey that involves continuous learning and adaptation. By implementing solid injection molding tips—like refining design features for manufacturability—you can enhance part stability while reducing waste and costs. Ultimately, staying informed about industry trends and collaborating with experts will pave the way for future innovations in high-heat applications.