Introduction

In the ever-evolving world of manufacturing, choosing affordable injection molding resins can significantly impact both product quality and production costs. With the increasing demand for efficient and cost-effective solutions, businesses are turning to injection moldable plastics that offer not just savings but also performance. This shift is largely driven by the rise of budget-friendly suppliers who provide high-quality materials without breaking the bank.

Why Choose Affordable Injection Molding Resins

Affordable injection molding resins present a compelling option for manufacturers looking to optimize their production processes while maintaining quality. By selecting cost-effective materials, companies can reduce overhead costs and improve profit margins, making it a win-win situation. Moreover, these resins often meet industry standards, allowing businesses to maintain competitive pricing without sacrificing performance.

The Rise of Cost-Effective Suppliers

The landscape of injection molding resin suppliers has transformed dramatically in recent years due to globalization and technological advancements. Cost-effective suppliers have emerged as key players, offering innovative solutions that cater to various manufacturing needs at lower prices. As a result, companies are now able to source high-quality plastic injection molding materials from diverse regions, enhancing their flexibility and competitiveness in the market.

What to Expect from Injection Molding Resin

When diving into the world of plastic injection molding, understanding what to expect from your chosen resin is crucial for success. Quality injection moldable plastics should offer excellent flow characteristics, dimensional stability, and durability under various conditions—key factors that influence the overall performance of molded products. Additionally, working with reputable plastic resin manufacturers ensures you receive materials that meet stringent compliance standards while also providing support throughout the entire injection molding process.

Understanding the Injection Molding Process

The injection molding process is a fascinating blend of science and artistry, transforming raw plastic resin into intricate designs that meet diverse needs. By leveraging the capabilities of injection molding resin suppliers, manufacturers can produce everything from everyday items to specialized components. Understanding this process is essential for anyone looking to dive into the world of plastic injection molding.

Basics of Plastic Injection Molding

At its core, plastic injection molding involves melting raw plastic resin and injecting it into a mold to create a desired shape. This method allows for high-volume production with exceptional precision, making it ideal for creating complex parts that would be difficult or costly to manufacture using other techniques. The efficiency of the plastic injection molding process also means shorter lead times and reduced waste, which are significant advantages in today’s fast-paced market.

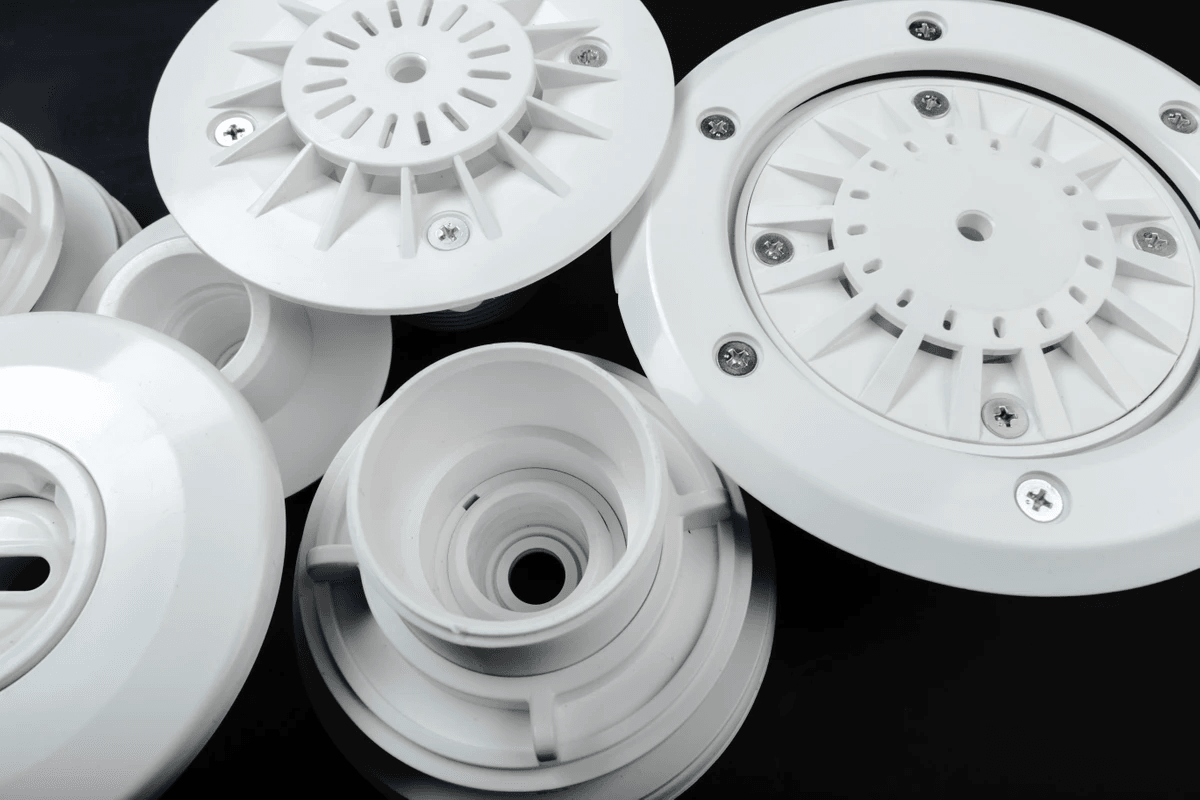

Once the molten resin fills the mold cavity, it cools and solidifies, forming a finished part ready for use or further processing. The versatility of this technique is evident in its wide range of applications—from automotive components to consumer electronics—showcasing how vital injection moldable plastics are in modern manufacturing. With advancements in technology and material science, the possibilities within this realm continue to expand.

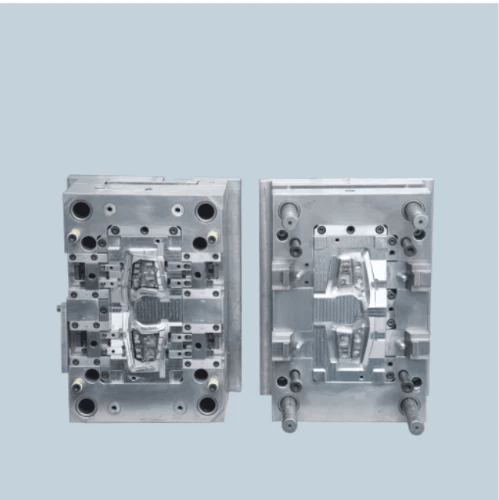

Key Components: Molds and Resin Types

Understanding the key components involved in mold plastic injection is crucial for anyone interested in optimizing their production processes. The two primary elements are molds themselves and various types of resins used during manufacturing. Molds are typically made from durable metals like steel or aluminum, designed to withstand high pressures while delivering precise shapes; they can be custom-designed for specific applications or purchased as standard options.

When it comes to resin types, there’s an array available—each offering distinct properties tailored for different applications. From thermoplastics that can be reheated and reshaped to thermosetting plastics that harden permanently upon curing, choosing the right type is essential for achieving desired performance characteristics. Collaborating with reputable plastic resin manufacturers ensures access to high-quality materials that enhance product durability and functionality.

Benefits of High-Quality Injection Molding

Investing in high-quality injection molding provides several benefits that can significantly impact your bottom line and product quality. Firstly, superior molds crafted by experienced professionals ensure consistent results with minimal defects throughout production runs—a crucial factor when working with injection molding resin suppliers who prioritize excellence. This consistency not only leads to better customer satisfaction but also reduces costs associated with rework and waste.

Additionally, utilizing top-tier materials allows manufacturers to produce parts that meet stringent industry standards while enhancing performance attributes like strength, flexibility, and thermal resistance. High-quality injection moldable plastics can withstand demanding conditions without compromising on integrity or appearance—making them ideal choices across various sectors including automotive, medical devices, and consumer goods. Ultimately, investing time upfront into selecting reliable suppliers pays dividends through enhanced productivity and profitability over time.

Top Injection Molding Resin Suppliers

When diving into the world of injection molding, selecting the right resin supplier can make all the difference. The landscape is filled with various options, from established giants to niche players specializing in unique materials. Understanding these suppliers will help you navigate the complexities of plastic injection molding and find the perfect fit for your production needs.

Spotlight on Baoyuan

Baoyuan has emerged as a strong contender among injection molding resin suppliers, known for its commitment to quality and affordability. With a diverse range of injection moldable plastics, Baoyuan caters to various industries, ensuring that clients receive tailored solutions that meet their specific requirements. Their focus on innovation within the plastic injection molding process allows them to stay ahead of trends while providing reliable products.

One of Baoyuan's standout features is their rigorous quality assurance practices, which ensure that every batch meets high standards before it reaches customers. This dedication not only enhances their reputation but also builds trust among manufacturers looking for dependable partners in plastic resin manufacturing. As businesses increasingly seek cost-effective solutions without compromising quality, Baoyuan remains a top choice in this competitive market.

Evaluating Supplier Quality and Reliability

When it comes to selecting injection molding resin suppliers, quality and reliability should be at the forefront of your decision-making process. The injection molding process can be complex, and the materials you choose can significantly impact the final product's durability and performance. Understanding how to evaluate potential suppliers ensures that you partner with those who prioritize quality assurance practices, robust production capabilities, and compliance with industry standards.

Importance of Quality Assurance Practices

Quality assurance practices are the backbone of any reputable plastic resin manufacturer. These practices ensure that each batch of injection moldable plastics meets specific standards for consistency, strength, and performance. By prioritizing suppliers with stringent quality control measures in place, you can minimize defects in your plastic injection molding projects and ensure a smoother production process.

Furthermore, effective quality assurance helps identify potential issues early on, reducing waste and saving costs in the long run. When evaluating injection molding resin suppliers, consider their track record for maintaining high-quality standards throughout their production processes. A strong commitment to quality will not only enhance your product's reliability but also foster a long-term partnership built on trust.

How to Assess Production Capabilities

Assessing the production capabilities of potential plastic injection molding partners is essential for ensuring they can meet your specific needs. Take a close look at their machinery—modern equipment often translates into more efficient mold plastic injection processes and higher-quality outputs. Additionally, inquire about their production capacity; understanding how much volume they can handle will help you gauge whether they can accommodate both current demands and future growth.

Another critical aspect is lead times—how quickly can they deliver? Timeliness is crucial in maintaining your own production schedules; delays from unreliable suppliers could ripple through your supply chain like a pebble causing waves in a pond. Finally, don’t hesitate to ask for samples or case studies showcasing their previous work; this tangible evidence will give you insight into their capabilities and help you make an informed decision.

Certifications and Compliance Standards

Certifications play an integral role in determining the credibility of injection molding resin suppliers within the industry. Look for certifications such as ISO 9001 or other relevant compliance standards that reflect a supplier’s commitment to maintaining high-quality manufacturing practices. These certifications indicate that a supplier adheres to strict guidelines regarding safety, environmental management, and customer satisfaction—key factors when working with various types of injection moldable plastics.

Moreover, compliance with industry regulations ensures that the materials used are safe for intended applications—especially crucial if you're producing items for consumer markets or sensitive industries like medical devices or food packaging. Always ask potential suppliers about their certifications during discussions; this information could save you from costly mistakes down the line while ensuring peace of mind regarding product safety.

Investing time in evaluating supplier quality through these lenses will not only streamline your plastic injection molding projects but also enhance overall product integrity as well as brand reputation.

Cost Considerations in Resin Selection

When selecting injection molding resins, cost considerations play a pivotal role in ensuring the success of your plastic injection molding projects. Striking the right balance between quality and affordability is essential for maintaining competitive pricing while meeting production standards. Understanding the financial implications of resin choices can lead to more informed decisions that align with both budget constraints and quality expectations.

Balancing Quality and Affordability

In the world of injection molding resin suppliers, finding the sweet spot between quality and cost is crucial. High-quality resins often come with a higher price tag, but they can save money in the long run by reducing defects and improving production efficiency. On the flip side, opting for cheaper alternatives may compromise product integrity, leading to increased waste and rework costs in your plastic injection molding process.

The key is to evaluate various plastic resin manufacturers to see which ones offer a good mix of performance and price. Consider not just the upfront costs but also how different resins perform under specific conditions; sometimes paying a little more upfront can result in significant savings later on. Ultimately, making informed choices about your injection moldable plastics can lead you to reliable suppliers that meet both your budgetary needs and quality expectations.

Hidden Costs in Plastic Injection Molding

While it might be tempting to focus solely on the sticker price of injection molding resins, hidden costs can lurk around every corner in the plastic injection molding process. Factors such as tooling adjustments, material waste during production, or even delays caused by subpar materials can significantly inflate overall expenses. It's essential to factor these potential pitfalls into your budgeting when selecting from various mold plastic injection options.

Moreover, consider logistics costs associated with sourcing materials from distant suppliers; shipping fees can add up quickly if you're not careful about choosing local or efficient vendors among injection molding resin suppliers. Comprehensive cost analysis should include maintenance expenses for machinery as well—certain resins may require more frequent cleaning or specialized equipment that could strain budgets over time. By being aware of these hidden costs, you can make wiser choices that contribute positively to your bottom line.

Bulk Purchase Advantages with Suppliers

One effective strategy for managing costs associated with resin selection is taking advantage of bulk purchasing options from reputable suppliers. Many plastic resin manufacturers offer discounts on larger orders, allowing businesses to stock up on necessary materials without breaking the bank at every purchase cycle. This not only helps reduce per-unit costs but also ensures consistent availability of high-quality injection moldable plastics for ongoing projects.

Additionally, building strong relationships with suppliers through regular bulk purchases often leads to better service terms and priority access during high-demand periods—an invaluable advantage when navigating fluctuating market conditions within the plastic industry. Establishing a rapport with reliable injection molding resin suppliers could also open doors for exclusive deals or early access to innovative products tailored specifically for your needs over time. By leveraging bulk purchasing strategies effectively, businesses can enjoy enhanced profitability while maintaining quality standards throughout their operations.

Trends and Innovations in Injection Molding

The injection molding landscape is rapidly evolving, with trends and innovations transforming how manufacturers approach production. From cutting-edge techniques to sustainable materials, the future of plastic injection molding promises enhanced efficiency and environmental responsibility. As businesses seek to optimize their operations, understanding these trends is essential for anyone involved in the injection molding process.

Advances in Mold Plastic Injection Techniques

Recent advancements in mold plastic injection techniques are revolutionizing the manufacturing sector. These innovations include multi-material injection molding, which allows for the creation of complex parts with varying properties within a single cycle. Additionally, technologies such as 3D printing integration into mold design have made it possible to produce intricate shapes that were previously challenging or impossible to achieve.

Moreover, automation plays a crucial role in enhancing production rates and reducing labor costs within the plastic injection molding industry. With robotic arms handling repetitive tasks and smart sensors monitoring quality throughout the process, manufacturers can ensure precision while minimizing human error. The result? Higher productivity levels and improved product consistency from leading injection molding resin suppliers.

Eco-Friendly Injection Moldable Plastics

As sustainability becomes a priority across industries, eco-friendly injection moldable plastics are gaining traction among plastic resin manufacturers. These materials are designed to reduce environmental impact while maintaining performance standards comparable to traditional resins. Biodegradable plastics derived from renewable resources are now available for various applications, allowing companies to meet consumer demand for greener products without compromising on quality.

In addition to biodegradable options, recycled plastics are also making waves in the market. By reusing post-consumer waste as feedstock for new products, manufacturers can significantly lower their carbon footprint while providing cost-effective solutions through collaboration with reliable injection molding resin suppliers. This shift toward sustainability not only benefits the environment but also enhances brand reputation among eco-conscious consumers.

The Future of Plastic Resin Manufacturing

Looking ahead, the future of plastic resin manufacturing appears bright as technological advancements continue to shape the industry landscape. Innovations such as AI-driven analytics are enabling manufacturers to optimize their processes by predicting equipment failures before they occur—reducing downtime and maintenance costs significantly during the plastic injection molding process.

Furthermore, increased collaboration between material scientists and engineers is paving the way for new formulations that offer improved performance characteristics tailored specifically for diverse applications across industries like automotive and healthcare. As this trend continues, businesses will find themselves better equipped to adapt swiftly to market demands while ensuring high-quality outcomes from their chosen injection moldable plastics.

In summary, staying informed about these trends will empower businesses involved in plastic injection molding not only to remain competitive but also lead initiatives that promote sustainability within their operations.

Conclusion

In the world of plastic injection molding, making informed choices about resin suppliers can significantly impact the quality and cost-effectiveness of your projects. With a plethora of options available, understanding the nuances of each supplier's offerings is essential to navigate this competitive landscape successfully. By focusing on reliable injection molding resin suppliers and their capabilities, you can ensure that your production needs are met efficiently.

Making Informed Choices for Resin Suppliers

Choosing the right injection molding resin suppliers requires careful consideration of their product range and reliability. Evaluate their experience in providing various types of injection moldable plastics that suit your specific requirements. Additionally, researching customer reviews and testimonials can offer insights into the supplier's service quality, ultimately guiding you toward a more informed decision.

Benefits of Working with Established Manufacturers

Partnering with established plastic resin manufacturers comes with numerous advantages that can streamline your production process. These manufacturers typically have robust quality assurance practices in place, ensuring that the materials you receive meet high standards for performance and durability. Moreover, established companies often provide better support and resources, helping you optimize your plastic injection molding operations while minimizing potential disruptions.

Navigating the Injection Molding Landscape

As you explore the injection molding process further, staying updated on trends and innovations is key to maintaining a competitive edge. The landscape of mold plastic injection is constantly evolving with advancements in technology and eco-friendly materials gaining traction among manufacturers. By keeping an eye on these developments and aligning with reputable injection molding resin suppliers, you'll be well-equipped to adapt to changes while enhancing your product offerings.