Introduction

Injection molding is a fascinating process that plays a pivotal role in the production of countless plastic products we use daily. From the toys that keep children entertained to the intricate components found in electronics, understanding injection molding basics is essential for anyone involved in plastic manufacturing. It’s a method that utilizes various types of injection molds to create complex shapes and designs with precision and efficiency.

Understanding Injection Molding Basics

At its core, plastic injection molding involves melting down thermoplastic or thermosetting polymers and injecting them into a mold to form specific shapes. This method allows for high-volume production of identical parts, making it an ideal choice for manufacturers looking to meet consumer demand efficiently. The types of injection molds used can significantly influence the quality and cost-effectiveness of the final product, highlighting the importance of mastering this fundamental process.

Importance of Choosing the Right Mold

Selecting the appropriate mold is crucial for achieving optimal results in plastic injection molding. Different applications may require different types of injection molds, each offering unique advantages tailored to specific needs. A well-chosen mold not only enhances production efficiency but also minimizes waste and reduces overall manufacturing costs, underscoring its significance in mold plastic injection.

Overview of Common Injection Mold Types

There are several common types of injection molds used in today’s manufacturing landscape, each serving distinct purposes based on project requirements. Single cavity molds are designed for producing one part at a time, while multi-cavity molds allow for multiple parts to be produced simultaneously, optimizing production rates. Understanding these various options—such as family molds and hot or cold runner systems—equips manufacturers with the knowledge needed to select the best solution for their specific applications.

Single Cavity Injection Molds

Single cavity injection molds are the simplest and most straightforward type of injection mold. They are designed to produce one part per cycle, making them ideal for small production runs or unique items that do not require mass manufacturing. In the realm of plastic injection molding, these molds serve as a foundational tool for creating various products using injection moldable plastics.

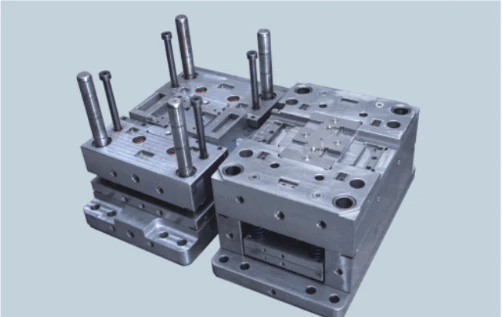

Definition and Functionality

A single cavity injection mold consists of two halves: the core and cavity, which work together to create a specific shape when melted plastic is injected into them. The functionality is straightforward; an injection machine mold melts the plastic, injects it into the mold, and allows it to cool before ejecting the finished part. This simplicity makes single cavity molds a popular choice for prototyping or low-volume production in plastic molding and manufacturing.

Advantages of Single Cavity Molds

One of the primary advantages of single cavity molds is their cost-effectiveness for small production runs. Since they only produce one part at a time, they require less upfront investment in terms of materials and machining compared to more complex types of injection molds like multi-cavity molds. Additionally, they offer greater flexibility for changes in design or material since adjustments can be made without affecting multiple cavities.

Applications in Plastic Manufacturing

Single cavity molds find their niche in various applications across different industries where precision and quality are paramount but large quantities are unnecessary. Common uses include custom parts for electronics, prototypes for automotive components, and specialized medical devices that require rigorous quality standards but don’t need mass production. This versatility makes them essential tools in plastic injection molding processes where unique designs meet practical needs.

Multi-Cavity Injection Molds

Multi-cavity injection molds represent a significant evolution in the realm of plastic injection molding. Unlike single cavity molds, which produce one part per cycle, multi-cavity molds can create multiple identical parts simultaneously, enhancing productivity and reducing manufacturing costs. This efficiency makes them a popular choice among manufacturers looking to optimize production while maintaining quality.

What are Multi-Cavity Molds?

Multi-cavity molds are designed to hold several cavities within a single mold base, allowing for the simultaneous production of multiple parts during each injection cycle. This design is particularly beneficial for high-volume production runs where consistency and speed are paramount. By utilizing injection moldable plastics in these molds, manufacturers can ensure that each produced item meets stringent quality standards while maximizing output.

Efficiency in Production

The efficiency of multi-cavity injection molds is one of their standout features, significantly reducing cycle times compared to single cavity counterparts. With the ability to produce several parts at once using an injection machine mold, manufacturers can ramp up production without compromising on the quality or precision of each part. This efficiency not only leads to lower operational costs but also helps businesses meet tight deadlines and respond quickly to market demands.

Key Use Cases in Industry

Multi-cavity molds find their place in various industries due to their versatility and effectiveness in mass production scenarios. Common applications include consumer goods, automotive components, and medical devices—areas where consistent quality and rapid turnaround times are essential. By leveraging plastic molding and manufacturing techniques with multi-cavity designs, companies can enhance their competitive edge in an ever-evolving marketplace.

Family Molds

Family molds are an innovative solution in the realm of plastic injection molding, allowing manufacturers to create multiple parts in a single cycle. This method involves designing a mold that can accommodate different shapes and sizes of injection moldable plastics within one unit. By utilizing family molds, companies can streamline their production processes and reduce costs associated with creating separate molds for each product.

Concept of Family Molding

At its core, family molding is about efficiency and versatility; it enables the production of various related parts simultaneously from one injection machine mold. This approach not only saves time during the manufacturing process but also minimizes the material waste often associated with traditional methods. The concept is particularly beneficial when dealing with products that share similar design characteristics or functional requirements, making it a popular choice in plastic molding and manufacturing.

Benefits for Diverse Product Lines

One of the standout benefits of using family molds is their ability to cater to diverse product lines without requiring extensive retooling or additional investment in multiple injection molding machine molds. Companies can produce different components—such as lids, containers, and other related items—all from a single mold setup, significantly enhancing productivity while reducing lead times. Moreover, this flexibility allows businesses to adapt quickly to changing market demands by easily modifying designs within the same mold framework.

Real-World Applications

Family molds find applications across various industries where versatility and efficiency are paramount—from consumer goods to automotive components. For instance, a manufacturer may use family molds to produce different parts for kitchen appliances like blenders or mixers, facilitating faster production cycles while maintaining quality standards in plastic injection molding. Additionally, businesses involved in packaging often leverage this technology to create multiple container types efficiently, showcasing how family molds can effectively meet diverse needs while optimizing resources.

Hot Runner Injection Molds

Hot runner injection molds have revolutionized the world of plastic injection molding, offering significant advantages over traditional cold runner systems. These molds utilize a heated manifold that keeps the plastic in a molten state as it travels to the cavities, ensuring that the material flows smoothly and efficiently. This system not only optimizes production speed but also enhances the quality of molded parts, making hot runners a popular choice in modern manufacturing processes.

How Hot Runner Systems Work

At the heart of hot runner systems is a network of heated channels that transport molten plastic from the injection machine mold to the cavities of the mold plastic injection setup. By maintaining a consistent temperature, these channels prevent premature cooling and solidification, which can lead to defects or inconsistencies in finished products. The design allows for precise control over material flow, resulting in better surface finishes and reduced waste—an essential factor when working with various types of injection molds.

Cost-Effectiveness and Efficiency

One of the standout benefits of hot runner systems is their cost-effectiveness in large-scale production runs. By minimizing scrap material—thanks to reduced waste during each cycle—manufacturers can achieve significant savings over time while maximizing their output efficiency. Additionally, because hot runners often require less energy to maintain temperatures compared to cold runners, they contribute positively to overall operational costs associated with plastic molding and manufacturing.

Industries Utilizing Hot Runners

Hot runner injection molds are widely adopted across various industries due to their versatility and efficiency. From automotive components that require high precision to consumer goods where aesthetic quality matters, hot runners serve as an integral part of many production lines involving injection moldable plastics. Industries such as electronics, medical devices, and packaging consistently benefit from this technology's ability to deliver superior results while shortening cycle times—a crucial factor in today's fast-paced market.

Cold Runner Injection Molds

Cold runner injection molds are an essential part of the plastic injection molding process, designed to optimize efficiency and reduce material waste. Unlike their hot runner counterparts, cold runner systems utilize a solidified channel to guide molten plastic into the mold cavities. This method is particularly advantageous for specific types of injection molds where cost considerations and material properties play a crucial role.

Overview of Cold Runner Systems

Cold runner systems consist of channels that transport molten plastic from the injection machine mold to the individual cavities in the mold. The key characteristic of these systems is that they allow the plastic to cool and solidify within the runners before being injected into the final product cavities. This setup can be beneficial for certain injection moldable plastics, as it simplifies manufacturing processes while minimizing maintenance requirements.

In a cold runner system, once the molding cycle is complete, any leftover plastic in the runners must be removed or recycled, which can lead to some material waste. However, this trade-off can often be justified by lower initial tooling costs and simpler designs compared to hot runner molds. Overall, understanding how cold runner systems function is crucial for manufacturers looking to optimize their plastic molding and manufacturing processes.

Advantages in Specific Scenarios

One significant advantage of cold runner injection molds lies in their cost-effectiveness when producing low-volume runs or prototypes. Since these molds typically have lower upfront costs than hot runners, they are ideal for projects where budget constraints are paramount or when testing new designs with injection moldable plastics. Additionally, because they require less complex heating mechanisms, maintenance tends to be easier and more affordable.

Another scenario where cold runners shine is with materials that are sensitive to thermal degradation during processing. By utilizing a cold runner system, manufacturers can minimize exposure time at high temperatures, preserving material integrity while still achieving excellent results in their final products made through mold plastic injection techniques. This makes them particularly suitable for certain engineering-grade polymers or recycled materials.

Typical Applications and Considerations

Cold runner molds find use across various industries due to their versatility and adaptability when working with different types of injection molds. They are commonly employed in applications such as consumer goods packaging components, automotive parts like clips and housings, as well as electronic enclosures that require precise dimensions without excessive waste generation during production cycles.

However, there are considerations manufacturers must keep in mind when opting for cold runners over other types of injection molds; namely cycle times may be longer due to cooling periods required for both runners and parts alike before ejection from the mold takes place. Additionally, if not managed correctly during production runs involving multiple colors or materials within one cycle using an injection molding machine mold setup could lead to contamination issues between different batches if proper cleaning protocols aren’t followed diligently.

In conclusion, while cold runner systems offer distinct advantages suited for specific scenarios—especially concerning budget constraints—they also necessitate careful planning regarding production timelines and material handling practices throughout each phase of development within your overall strategy involving plastic molding and manufacturing initiatives.

Conclusion

In the world of plastic injection molding, selecting the right type of injection mold is crucial for achieving optimal results in manufacturing. With various options available—such as single cavity, multi-cavity, family molds, hot runner, and cold runner systems—each type serves specific purposes and offers distinct advantages. Understanding these differences can significantly impact production efficiency, cost-effectiveness, and ultimately the quality of the finished product.

Choosing the Right Type of Injection Mold

When it comes to choosing between types of injection molds, several factors must be considered. These include production volume, complexity of design, and material compatibility with injection moldable plastics. By aligning your project requirements with the characteristics of each mold type—be it a plastic injection molding mold or an injection machine mold—you can ensure a smoother manufacturing process.

Moreover, it's essential to evaluate how each type affects turnaround time and overall costs in plastic molding and manufacturing. For instance, while multi-cavity molds may offer higher output rates for larger runs, single cavity molds could be more suitable for intricate designs or smaller batches. Ultimately, making an informed decision will lead to better resource allocation and enhanced production capabilities.

Future Trends in Injection Molding

The future of plastic injection molding is poised for exciting advancements driven by technology and sustainability efforts. Innovations like smart manufacturing techniques are being integrated into traditional processes to improve efficiency and reduce waste in using injection molding machine molds. Additionally, there's a growing trend towards utilizing eco-friendly materials that are compatible with various types of injection molds.

Furthermore, automation in the form of advanced robotics is set to revolutionize how we approach plastic molding and manufacturing processes. This shift not only streamlines operations but also enhances precision in producing complex components with minimal human intervention. As industries continue to evolve towards more sustainable practices while maintaining high-quality standards, staying abreast of these trends will be vital for manufacturers seeking competitive advantages.

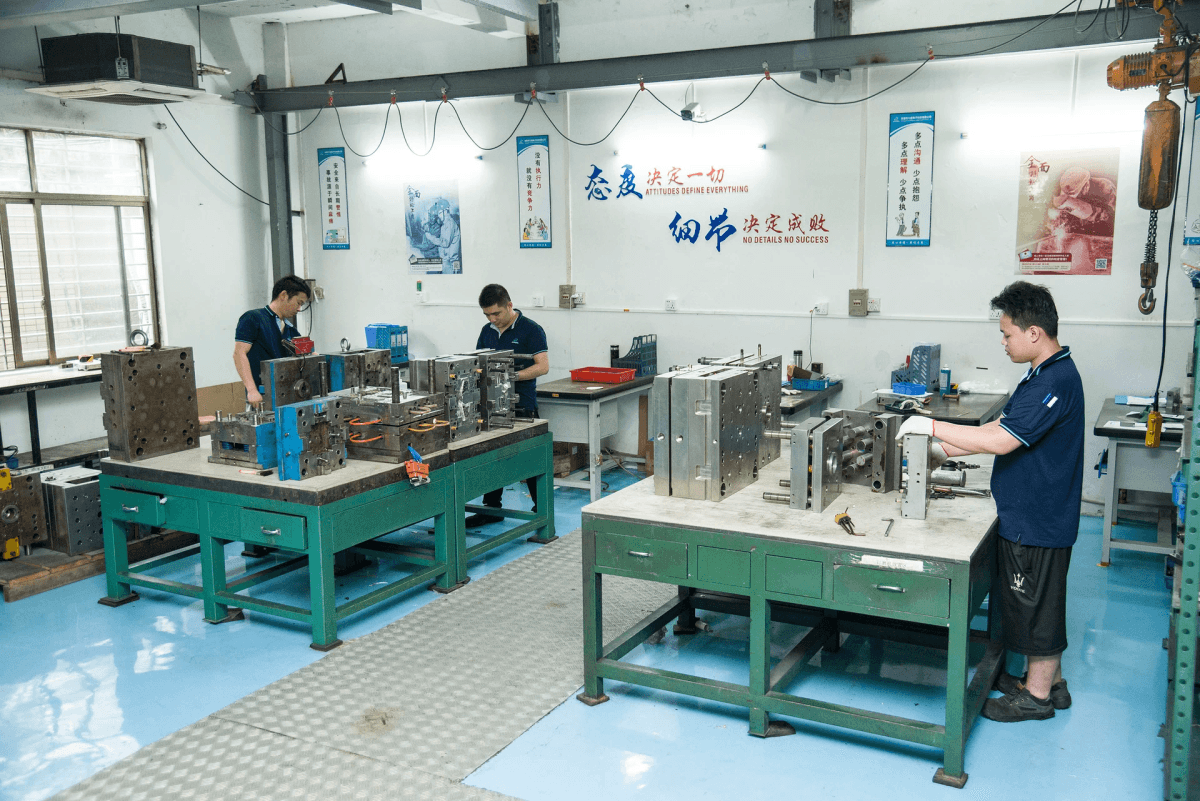

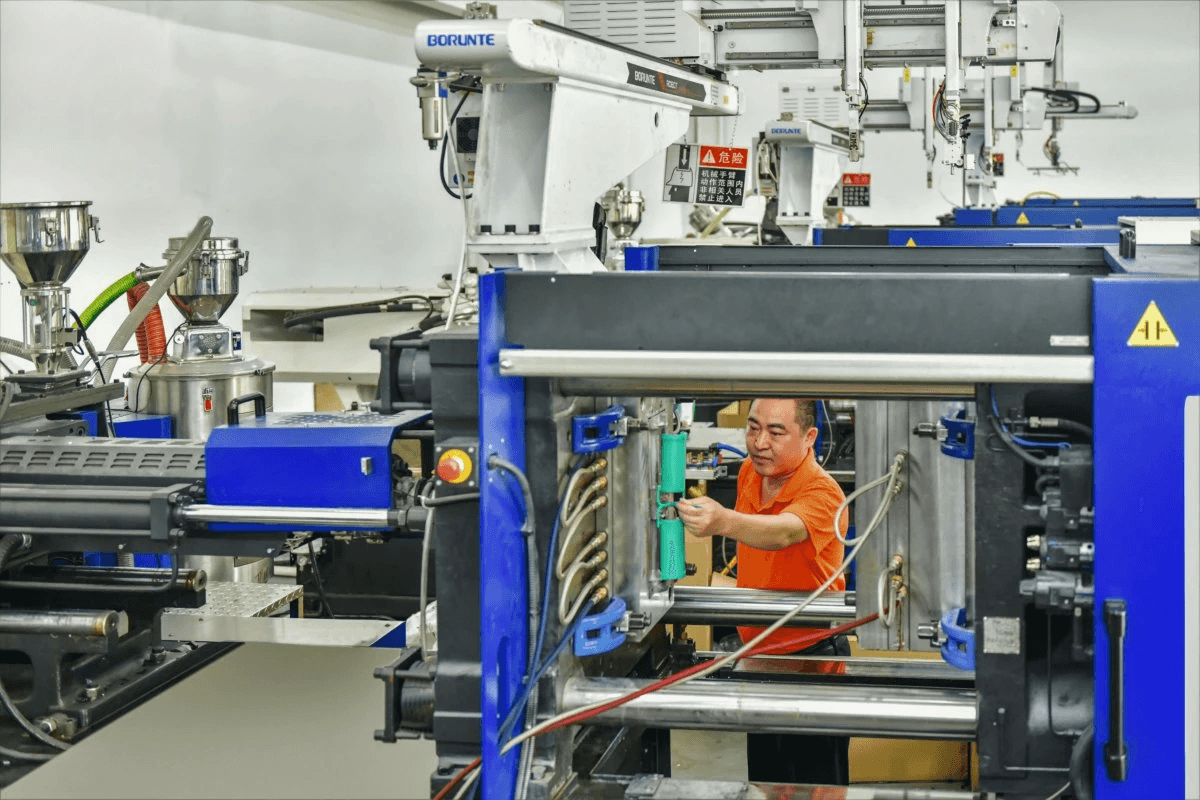

Why Baoyuan Stands Out in Molding Solutions

Baoyuan has established itself as a leader in providing comprehensive solutions tailored to meet diverse needs within the realm of plastic injection molding. With expertise spanning various types of injection molds—including hot runners and family molds—the company excels at delivering customized designs that optimize production efficiency while minimizing costs associated with mold plastic injection processes.

What sets Baoyuan apart is its commitment to innovation; they continually invest in cutting-edge technologies that enhance both product quality and operational performance across all stages—from design through implementation using state-of-the-art equipment like advanced injection machines. Their dedication extends beyond just offering products; Baoyuan provides exceptional customer support that ensures clients make informed decisions regarding their specific requirements for any project involving injection moldable plastics.