Introduction

In today's world, the significance of manufacturing plastic products cannot be overstated. From everyday household items to advanced industrial components, plastics play a vital role in various sectors. Understanding the processes behind plastic manufacturing is essential for businesses looking to enhance their product offerings and optimize production efficiency.

Understanding the Importance of Plastic Manufacturing

Plastic manufacturing has transformed industries by providing versatile and cost-effective solutions for a wide range of applications. With advancements in technology, manufacturers can produce high-quality plastic injection molding services that meet specific customer needs. The ability to customize injection moldable plastics allows companies to innovate and stay competitive in an ever-evolving market.

Overview of Manufacturing Plastic Products

The process of manufacturing plastic products involves several stages, including material selection, design, and production methods like injection molding. Each step is crucial in ensuring that the final product meets quality standards while being economically viable. By partnering with a reputable plastic manufacturing company, businesses can leverage expertise in producing durable and efficient plastic goods tailored to their requirements.

Key Processes in Plastic Production

Among the key processes in plastic production, injection molding stands out due to its efficiency and precision. This method allows for the mass production of intricate designs with minimal waste, making it a preferred choice for many manufacturers. Additionally, understanding these processes enables companies to make informed decisions when selecting a provider for their plastic injection moulding service needs.

The Basics of Plastic Manufacturing

Understanding the fundamentals of plastic manufacturing is essential for anyone involved in producing or using plastic products. This section explores the various types of plastic materials, common applications for injection moldable plastics, and why selecting the right plastic manufacturing company is crucial for success. With the right knowledge, businesses can optimize their operations and ensure high-quality outcomes.

Types of Plastic Materials

Plastic materials come in a variety of forms, each with unique properties that make them suitable for different applications. Common types include thermoplastics like polyethylene and polypropylene, which can be melted and reshaped multiple times without significant degradation. On the other hand, thermosetting plastics such as epoxy resin harden permanently after being molded, offering durability in high-temperature environments.

When choosing materials for manufacturing plastic products, it's vital to consider factors such as strength, flexibility, and resistance to chemicals or UV light. The choice often influences not just performance but also production costs and sustainability aspects. By understanding these different types of plastics, manufacturers can better select appropriate materials for their specific needs.

Common Applications of Injection Moldable Plastics

Injection moldable plastics are used across a wide range of industries due to their versatility and cost-effectiveness. From automotive components to consumer electronics casings, these materials play an integral role in everyday products we often take for granted. Their ability to be molded into complex shapes makes them ideal for creating everything from intricate gears to simple containers.

In addition to automotive and electronics sectors, injection moldable plastics are also widely used in medical devices and packaging solutions. These applications require strict adherence to quality standards due to safety concerns; thus, reliable plastic injection molding services are crucial here. The adaptability of injection molding allows manufacturers to produce large quantities efficiently while maintaining precise specifications.

Importance of Selecting a Plastic Manufacturing Company

Choosing the right plastic manufacturing company can significantly impact your project's success and overall product quality. A reputable company will not only provide top-notch plastic injection moulding service but also offer expertise in material selection and design optimization tailored to your needs. Partnering with experienced professionals ensures that your project stays on schedule while adhering to budget constraints.

Moreover, a reliable manufacturer will implement stringent quality control measures throughout the production process—ensuring consistency in every batch produced is key when dealing with injection molding services. This commitment helps avoid costly reworks or defects that could tarnish your brand's reputation or lead to safety issues down the line. Ultimately, investing time in selecting a competent partner pays off through enhanced product performance and customer satisfaction.

Exploring Injection Molding

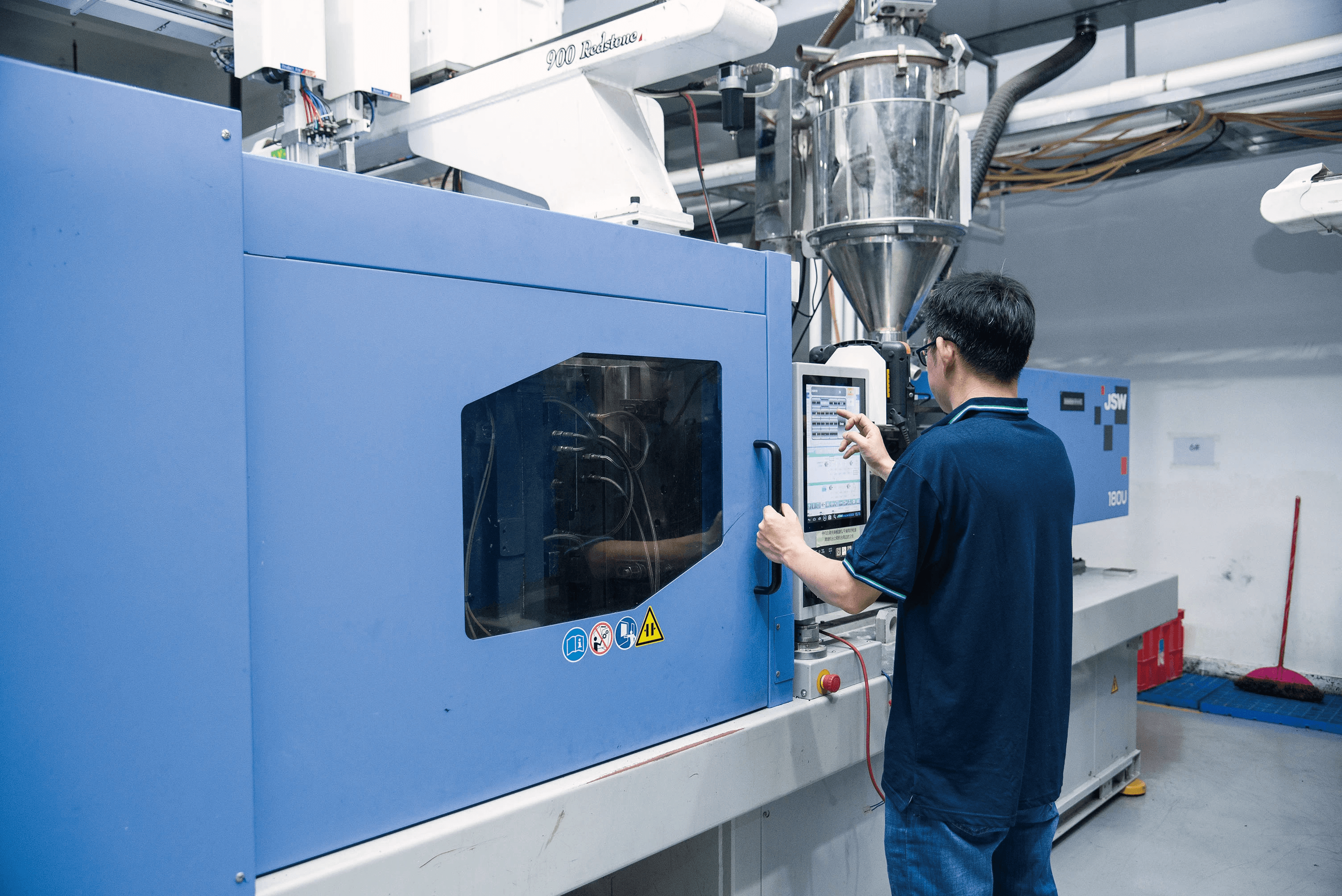

Injection molding is a cornerstone of modern plastic manufacturing, allowing for the efficient production of complex shapes and designs. In this process, heated plastic material is injected into a precisely designed mold, where it cools and solidifies into the final product. This method not only ensures high production rates but also offers remarkable accuracy and repeatability in manufacturing plastic products.

How Injection Molding Works

The injection molding process begins with the selection of raw plastic pellets that are heated until they melt. Once liquefied, the molten plastic is injected under pressure into a mold cavity, which shapes the material into the desired form. After cooling for a brief period, the mold opens to release the finished product, which can then undergo additional finishing processes if necessary.

Understanding how injection molding works is crucial for anyone involved in choosing a plastic manufacturing company. The precision of this technique allows manufacturers to create intricate designs that might be impossible with other methods. Furthermore, it supports large-scale production runs without compromising quality—making it an ideal choice for businesses looking to produce injection moldable plastics efficiently.

Benefits of Plastic Injection Molding Services

One major benefit of utilizing plastic injection molding services is cost-effectiveness over large production volumes. Once the initial investment in molds has been made, producing additional units becomes significantly cheaper than other methods like machining or 3D printing. Additionally, injection molding allows for minimal waste generation since excess material can often be recycled back into the process.

Another advantage lies in design flexibility; manufacturers can experiment with different materials and colors without extensive retooling efforts. This versatility enables companies to innovate their products continuously while meeting diverse market demands effectively. With skilled providers offering specialized plastic injection moulding service options, businesses can achieve tailored solutions that enhance their competitive edge.

Common Industries Using Injection Molding

Injection molding finds applications across various industries due to its versatility and efficiency in manufacturing plastic products. The automotive sector relies heavily on this technique for producing components such as dashboards and interior fittings that require durability and aesthetic appeal. Similarly, consumer goods industries leverage injection molding to create everything from packaging materials to household items like toys and kitchenware.

In addition to automotive and consumer goods sectors, medical equipment manufacturing also benefits significantly from injection molding services due to stringent quality requirements and precise component specifications needed for safety-critical applications. Electronics manufacturers utilize this method as well; creating intricate housings that protect sensitive components while providing an attractive finish is essential in today’s tech-driven world. Overall, whether it's healthcare or home appliances, numerous industries recognize the value of partnering with experienced professionals specializing in injection molding techniques.

The Role of Mold Design

Mold design is a critical component in the manufacturing plastic products process, particularly when it comes to injection molding. Precision in mold design directly influences the quality, efficiency, and cost-effectiveness of production. A well-designed mold ensures that the final product meets specifications while minimizing waste and maximizing productivity.

Importance of Precision in Mold Design

Precision in mold design is paramount for achieving high-quality results in plastic injection molding services. Even the slightest deviation can lead to defects, increased cycle times, and higher costs, making it essential for manufacturers to prioritize accuracy. Moreover, precise molds enable the effective use of injection moldable plastics, ensuring that each product produced is consistent and reliable.

When selecting a plastic manufacturing company for your needs, understanding their approach to mold design can provide insight into their overall quality assurance practices. Companies that invest time and resources into precision engineering are often better equipped to deliver superior products. Ultimately, precision in mold design not only affects individual projects but also contributes to long-term relationships between manufacturers and clients.

Software Tools for Mold Design

In today's digital age, software tools play a vital role in enhancing the effectiveness of mold design processes within plastic manufacturing. Advanced CAD (Computer-Aided Design) software allows engineers to create intricate designs that cater specifically to the requirements of various injection molding applications. These tools enable simulations that predict how molds will perform under different conditions, helping manufacturers refine their designs before physical production begins.

Additionally, software solutions facilitate collaboration among teams by allowing real-time adjustments and sharing of information across departments. This integration streamlines workflows and reduces errors during the production phase—crucial factors when dealing with complex plastic injection moulding service projects. By leveraging technology effectively, companies can enhance their capabilities in creating high-quality molds tailored for specific applications.

How Baoyuan Ensures Quality Mold Creation

At Baoyuan, ensuring quality mold creation is at the heart of our operations within the plastic manufacturing industry. We employ state-of-the-art technology alongside skilled professionals who understand every nuance involved in designing effective molds for injection molding processes. Our commitment to precision means we utilize advanced software tools coupled with rigorous testing procedures throughout development.

Moreover, Baoyuan's extensive experience allows us to quickly identify potential issues before they escalate into costly problems during production runs—keeping your project on track and within budget while maintaining high standards for quality control over our plastic injection molding services. By focusing on both innovation and tradition in our approach to mold design, we ensure that every product meets or exceeds client expectations while adhering strictly to industry standards.

Advanced Manufacturing Techniques

In the ever-evolving landscape of plastic manufacturing, advanced techniques such as blow molding and extrusion play a pivotal role in producing high-quality plastic products. These methods not only enhance efficiency but also broaden the range of applications for injection moldable plastics. As manufacturers strive to meet diverse consumer needs, understanding these techniques becomes essential for anyone involved in manufacturing plastic products.

Overview of Blow Molding and Extrusion

Blow molding is a fascinating process that allows manufacturers to create hollow plastic parts by inflating heated material within a mold. This method is particularly popular for producing bottles, containers, and other hollow items that require durability and lightweight properties. On the other hand, extrusion involves forcing molten plastic through a die to create continuous shapes like pipes, sheets, or films—ideal for various industrial applications.

For instance, blow molding provides excellent flexibility in design while ensuring uniform wall thickness in the final product. Conversely, extrusion is celebrated for its efficiency and ability to produce long lengths of material without interruption—making it a go-to choice for many industries relying on consistent supply chains.

Comparison of Different Plastic Production Methods

When considering different methods of plastic production, it's crucial to weigh the pros and cons of each technique against your specific needs. Injection molding stands out due to its ability to produce complex shapes with high precision at an impressive speed—perfect for mass production runs where consistency is key. However, methods like blow molding offer distinct benefits when creating larger hollow items that injection molding simply cannot replicate.

Moreover, while injection moldable plastics can be tailored through various additives during the injection process, extrusion allows manufacturers to create customized profiles that are otherwise difficult to achieve with traditional methods. Each method has its niche; thus, selecting the right one often depends on factors such as product design complexity, volume requirements, and cost considerations—a task best handled with guidance from a reputable plastic manufacturing company.

Innovations in Plastic Manufacturing Technology

The world of plastic manufacturing is witnessing groundbreaking innovations that promise to reshape how we think about materials and processes alike. Advances in 3D printing technology are allowing companies to create prototypes rapidly while reducing waste—a significant concern in traditional manufacturing practices including injection molding services. Furthermore, developments in bioplastics are paving the way for more sustainable options within an industry historically dominated by petroleum-based materials.

Additionally, smart technologies such as IoT (Internet of Things) integration enable real-time monitoring during production runs—enhancing quality control measures significantly across all types of plastic production methods including both blow molding and extrusion processes. As these innovations continue to emerge at breakneck speed, they present exciting opportunities for manufacturers eager to stay ahead in a competitive market focused on sustainability and efficiency.

Quality Control in Plastic Production

In the world of manufacturing plastic products, quality control is paramount. Ensuring that each batch of plastic meets the required specifications not only fosters customer trust but also minimizes waste and rework costs. A robust quality control system is essential for maintaining consistency in the production of injection moldable plastics.

Ensuring Consistency in Plastic Products

Variations in material properties or production processes can lead to defects, which can compromise the integrity and usability of injection molded items. By implementing stringent quality control measures, manufacturers can ensure that every piece produced through their plastic injection moulding service meets established standards.

To achieve this consistency, companies often employ advanced monitoring techniques during the manufacturing process. This includes real-time data collection on temperatures, pressures, and material flow rates during injection molding cycles. Such meticulous attention to detail helps to identify any anomalies early on, ensuring that only top-notch plastic manufacturing products reach consumers.

Quality Assurance Practices in the Industry

Quality assurance practices play a crucial role in maintaining high standards across the plastic manufacturing sector. Many companies utilize ISO certification as a benchmark for their processes, ensuring they adhere to international quality management standards. This not only enhances product reliability but also boosts consumer confidence in their manufacturing plastic products.

Regular audits and inspections are standard procedures within leading manufacturing firms specializing in injection molding services. These practices help identify potential areas for improvement and ensure compliance with industry regulations regarding safety and environmental impact. Furthermore, continuous training of staff involved in these processes ensures they remain updated on best practices and technological advancements.

Role of Baoyuan in Enhancing Production Quality

Baoyuan stands out as a leader among plastic manufacturing companies by prioritizing quality at every stage of production. With a commitment to excellence, Baoyuan employs state-of-the-art technology alongside skilled professionals dedicated to perfecting their craft within the realm of injection molding services. This combination results in superior precision when creating molds for various applications.

The company’s rigorous testing protocols further enhance its reputation for producing reliable injection moldable plastics that meet stringent industry standards. By focusing on both innovation and tradition, Baoyuan ensures that its clients receive consistent quality while adapting to new trends within the industry landscape. Ultimately, partnering with a company like Baoyuan means investing in unparalleled expertise that guarantees superior results in your next project involving plastic injection moulding service.

Conclusion

As we wrap up our exploration of plastic manufacturing, it's clear that the industry is not just about creating everyday items; it's about innovation and adaptation to meet modern needs. The future of manufacturing plastic products lies in sustainable practices, advanced technologies, and a focus on quality. As trends shift towards eco-friendly materials and processes, staying ahead means embracing these changes while maintaining the integrity of plastic injection molding services.

Future Trends in Plastic Manufacturing

One of the most exciting trends in plastic manufacturing is the push towards sustainability. Manufacturers are increasingly incorporating recycled materials into their production processes, which not only helps reduce waste but also appeals to environmentally conscious consumers. Additionally, advancements in bioplastics are paving the way for more sustainable alternatives to traditional injection moldable plastics.

Automation and smart technology are also shaping the future landscape of plastic manufacturing. With the integration of AI and IoT, companies can streamline their operations, enhance precision in injection molding, and improve overall efficiency. As these technologies evolve, they will redefine how plastic products are manufactured and delivered to market.

Finally, customization is becoming a crucial aspect of the industry as consumers demand more personalized solutions. This trend encourages manufacturers to offer tailored services in areas like plastic injection moulding service while maintaining high-quality standards across various applications. The ability to adapt quickly will be key for companies looking to thrive in this dynamic environment.

Choosing the Right Manufacturing Partner

Selecting a reliable plastic manufacturing company is vital for achieving high-quality outcomes in your projects. It's important to consider factors such as experience, reputation, and expertise when evaluating potential partners for your production needs. A trusted partner will not only provide quality assurance but also help navigate challenges associated with producing complex designs using injection molding techniques.

Moreover, collaboration with an experienced manufacturer can lead to enhanced innovation during product development stages. They can offer insights into material selection and design optimization that align with current trends in efficient production practices—especially when it comes to using advanced techniques like blow molding or extrusion alongside traditional methods.

In today’s competitive market landscape, finding a partner who understands your specific requirements can make all the difference between success and failure in launching new products or improving existing ones.

Advantages of Working with Experienced Professionals

Working with seasoned professionals within the realm of plastic manufacturing offers numerous advantages that can significantly impact your project's success rate. Their extensive knowledge allows them to anticipate potential issues before they arise—saving time and resources during production processes like injection moldable plastics fabrication or assembly line management.

Additionally, experienced manufacturers often have established relationships with suppliers which can lead to better pricing on raw materials while ensuring consistency across batches produced through their plastic injection molding services. This network not only enhances product quality but also ensures timely delivery—a crucial factor for meeting market demands efficiently.

Lastly, partnering with professionals who prioritize quality control means you benefit from rigorous testing protocols designed to maintain product integrity throughout every stage of production—from initial design through final inspection—ultimately contributing positively toward your brand's reputation within various industries reliant on high standards for their manufacturing plastic products.