Introduction

In the rapidly evolving world of automotive manufacturing, the significance of automotive injection molding has surged to unprecedented heights. This process not only streamlines production but also enhances the quality and durability of auto parts, making it a cornerstone for auto parts manufacturers looking to stay competitive. As a result, understanding the dynamics of automotive plastics suppliers becomes essential for companies aiming to thrive in this fast-paced industry.

The Rise of Automotive Injection Molding

Automotive injection molding has emerged as a game-changer in the production of plastic components for vehicles. With its ability to produce complex shapes and designs at high volumes, this technique is favored by many automotive parts manufacturers seeking efficiency and precision. As demand for lightweight yet durable materials grows, plastic manufacturers are stepping up their game, ensuring that the latest innovations in injection molding technology are readily accessible.

Why Choosing the Right Supplier Matters

Selecting the right supplier can make or break an auto parts manufacturer’s success story. A reliable partner among automotive plastics suppliers ensures not only access to high-quality materials but also adherence to industry standards and regulations that safeguard vehicle safety and performance. With countless options available, understanding how to evaluate supplier capabilities is crucial for businesses aiming to secure their place in a competitive market.

Baoyuan’s Role in Automotive Parts Manufacturing

Baoyuan stands out as a trusted name among automotive plastics suppliers, offering a comprehensive range of services tailored specifically for automotive manufacturing needs. With expertise in mold design and production, Baoyuan helps streamline processes while ensuring top-notch quality across all products. Their commitment to innovation and customer satisfaction positions them as an indispensable ally for any auto parts manufacturer striving for excellence.

Understanding Automotive Injection Molding

Injection molding is a transformative process that has revolutionized the way automotive parts are manufactured. This technique involves injecting molten plastic into a mold, where it cools and solidifies into the desired shape. As a result, automotive plastics suppliers can produce complex and precise components efficiently, making it a favored method among auto parts manufacturers.

What is Injection Molding?

At its core, injection molding is about precision and efficiency. The process begins with heated plastic pellets being fed into a machine where they are melted down to a liquid state. Once in this form, the molten plastic is injected into meticulously crafted molds that define the final shape of the part, allowing automotive parts manufacturers to create everything from intricate dashboards to robust bumpers.

This method not only ensures high levels of accuracy but also allows for mass production without compromising quality. As such, it stands as one of the most widely adopted techniques in automotive manufacturing today. By utilizing advanced machinery and technology, plastic manufacturers can streamline production while meeting rigorous industry standards.

Benefits of Injection Molding in Auto Parts

The advantages of injection molding extend far beyond just creating shapes; it's about optimizing performance and costs too. For one, this technique significantly reduces waste compared to traditional manufacturing methods since excess material can often be recycled back into production. Additionally, because molds can be reused thousands of times, automotive plastics suppliers benefit from lower long-term costs and increased profit margins.

Moreover, injection molding allows for rapid prototyping and design iterations which are crucial for staying competitive in the fast-paced automotive industry. With shorter lead times on new product designs, auto parts manufacturers can quickly adapt to market demands or introduce innovative features that enhance vehicle performance. This agility not only fosters creativity but also drives innovation across various segments of automotive manufacturing.

Key Techniques and Technologies Used

In the realm of injection molding, several techniques have emerged that cater specifically to the needs of automotive parts manufacturers. One notable method is multi-material injection molding which enables different types of plastics to be combined within a single component—perfect for creating complex assemblies with unique properties like enhanced durability or flexibility.

Additionally, advancements like computer-aided design (CAD) software allow engineers at plastic manufacturers to simulate mold designs digitally before physical production begins—saving time and resources by identifying potential issues early on in the process. Furthermore, technologies such as 3D printing are increasingly being integrated with traditional injection molding practices to facilitate rapid prototyping for new designs.

These innovations not only enhance productivity but also improve product quality across the board—making them indispensable tools for any serious player among automotive plastics suppliers looking to thrive in an ever-evolving market landscape.

Top Automotive Plastics Suppliers

When it comes to automotive manufacturing, selecting the right automotive plastics suppliers is paramount for success. The industry is filled with numerous players, each vying for a spot in the competitive landscape of auto parts manufacturers. Understanding which suppliers stand out can make all the difference in producing high-quality automotive components.

Leading Companies in the Industry

Among the leading automotive plastics suppliers are companies like BASF, DuPont, and Covestro, known for their innovative materials and solutions tailored for auto parts manufacturers. These companies have invested heavily in research and development to create advanced polymers that not only meet but exceed industry standards. Their commitment to quality has solidified their positions as trusted partners for automotive parts manufacturers around the globe.

Another noteworthy contender is SABIC, which has carved a niche with its sustainable plastic solutions aimed at reducing environmental impact without compromising performance. As electric vehicles gain traction, these leading plastic manufacturers are adapting their offerings to meet new demands from auto parts manufacturers who require lightweight and durable materials. Overall, these companies set the benchmark for excellence within the automotive manufacturing sector.

How to Evaluate Supplier Capabilities

Evaluating supplier capabilities is essential when choosing among various automotive plastics suppliers; after all, not all suppliers are created equal! Start by assessing their production capacity and technological capabilities—can they scale up production if needed? Additionally, consider their experience in working with specific types of auto parts; familiarity with your product line can enhance efficiency and reduce lead times.

You should also investigate their certifications and compliance with industry standards such as ISO 9001 or IATF 16949; these credentials indicate a commitment to quality management systems crucial for automotive manufacturing. Furthermore, look into customer reviews or case studies that highlight past successes or challenges faced by potential suppliers; this insight can provide valuable context regarding reliability and performance under pressure.

Lastly, don't underestimate the importance of communication—an open dialogue about expectations can foster a successful partnership between you and your chosen supplier.

The Importance of Quality Assurance in Automotive Plastics

Quality assurance plays a critical role in maintaining high standards within the realm of automotive plastics suppliers. Given that even minor defects can lead to significant safety issues or costly recalls in automotive manufacturing, rigorous quality control measures are non-negotiable among reputable auto parts manufacturers. Implementing thorough testing protocols ensures that every component meets stringent requirements before reaching end-users.

Moreover, quality assurance helps build trust between you and your supplier; knowing they prioritize excellence allows you to focus on other aspects of your business without worrying about product reliability. It’s worth noting that many top-tier plastic manufacturers invest heavily in continuous improvement processes—this commitment not only enhances product quality but also streamlines operations over time.

In conclusion, understanding how to evaluate supplier capabilities alongside recognizing the importance of quality assurance will empower you as an informed decision-maker when navigating partnerships with automotive plastics suppliers.

Baoyuan: A Trusted Name in the Industry

When it comes to automotive manufacturing, Baoyuan stands out as a reliable partner for auto parts manufacturers seeking high-quality solutions. With a commitment to innovation and excellence, Baoyuan has carved a niche in the competitive landscape of automotive plastics suppliers. Their comprehensive services span from design to production, ensuring that clients receive top-notch products tailored to their specific needs.

Overview of Baoyuan’s Services

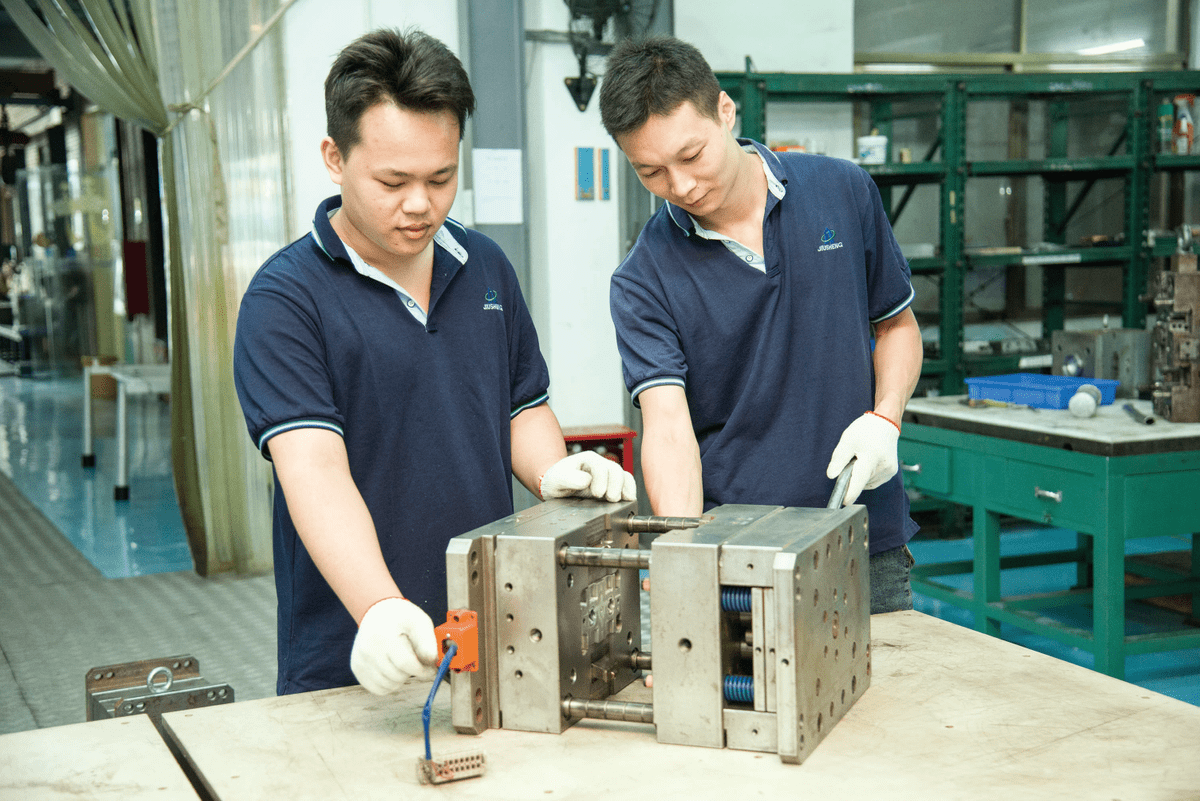

Baoyuan offers a wide array of services designed specifically for the automotive sector, making them a preferred choice among automotive parts manufacturers. Their offerings include custom mold design, precision injection molding, and extensive post-production processes that enhance product durability and performance. By leveraging cutting-edge technology and skilled craftsmanship, Baoyuan ensures that every component meets stringent industry standards while also satisfying customer expectations.

In addition to traditional services, Baoyuan emphasizes collaboration with clients throughout the entire manufacturing process. This partnership approach allows them to adapt quickly to changing demands in automotive manufacturing while maintaining cost efficiency. With an unwavering focus on quality control and timely delivery, Baoyuan positions itself as a leader among automotive plastics suppliers.

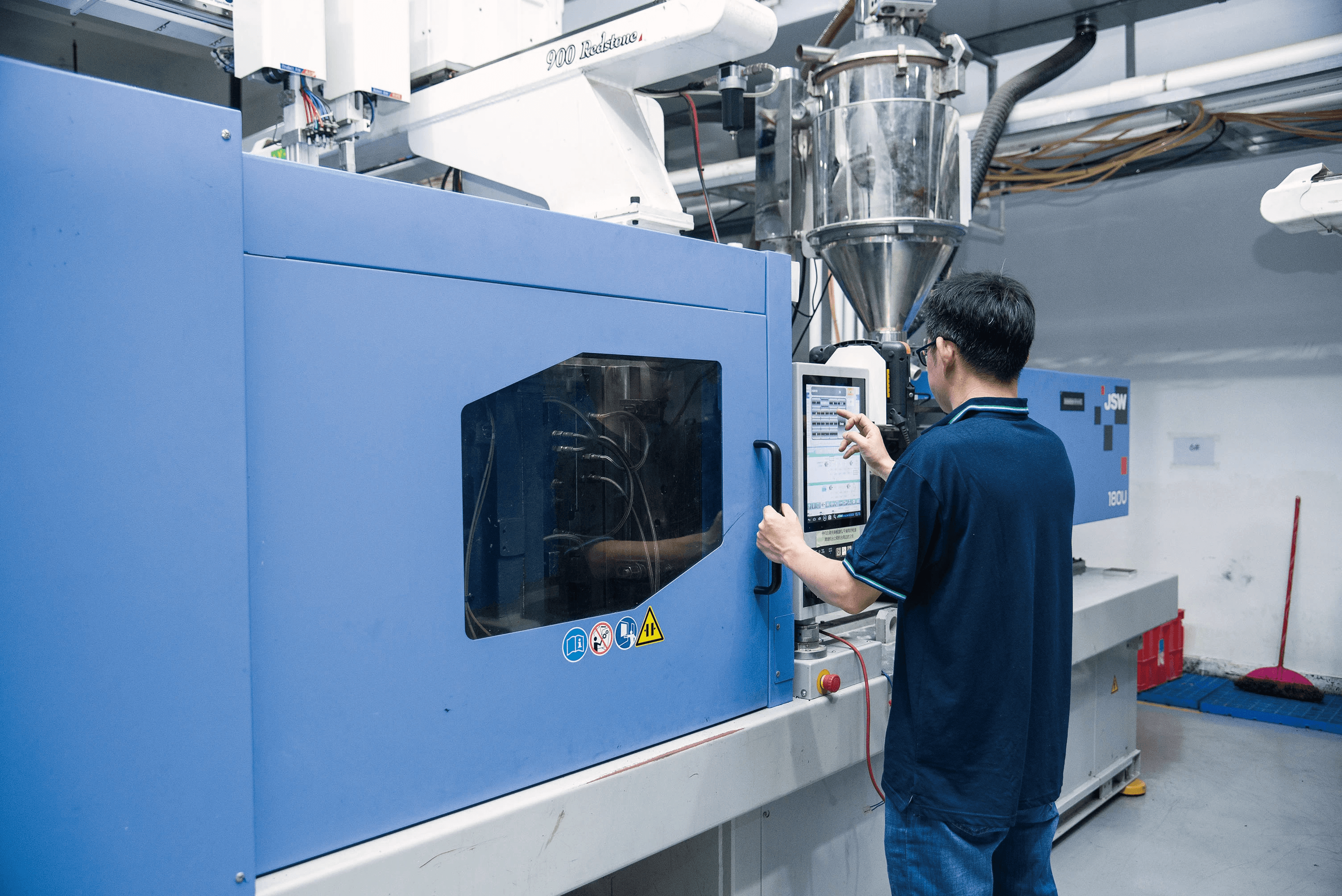

Expertise in Mold Design and Production

One of Baoyuan's standout features is its expertise in mold design and production, which is crucial for any successful auto parts manufacturer. Their experienced team utilizes advanced software tools to create intricate molds that are both efficient and precise, catering specifically to the unique requirements of each project. This level of specialization not only enhances the quality of finished products but also reduces lead times significantly.

Moreover, Baoyuan continually invests in state-of-the-art machinery that allows for rapid prototyping and testing phases within their mold-making process. This investment ensures that they stay ahead of industry trends while providing innovative solutions for their clients' needs in automotive manufacturing. As such, they have become synonymous with reliability among plastic manufacturers looking for high-quality components.

Success Stories in Automotive Manufacturing

Baoyuan's reputation as a trusted name among automotive plastics suppliers is further solidified by its impressive portfolio of success stories within the industry. They have collaborated with various leading auto parts manufacturers on projects ranging from interior components to intricate exterior systems—each time delivering exceptional results that exceed expectations. These partnerships highlight their ability to adapt their expertise across different facets of automotive manufacturing.

One notable success involved developing lightweight yet durable components for an electric vehicle manufacturer aiming to enhance energy efficiency without compromising safety standards. By employing innovative materials alongside their advanced molding techniques, Baoyuan contributed significantly to this project's success—a testament to their adaptability within the evolving landscape of auto parts manufacturing. As they continue forging new paths through collaboration and innovation, it's clear why so many trust Baoyuan as their go-to partner.

Sustainable Practices in Automotive Manufacturing

In the rapidly evolving landscape of automotive manufacturing, sustainability has become a key focus for auto parts manufacturers. As environmental regulations tighten and consumer preferences shift towards greener products, the role of automotive plastics suppliers is more critical than ever. This section explores eco-friendly materials, the responsibilities of plastic manufacturers, and innovative practices that are paving the way for a sustainable future in auto parts manufacturing.

Eco-Friendly Materials in Auto Parts

The push for sustainability in automotive manufacturing has led to an increased interest in eco-friendly materials for auto parts. Many automotive plastics suppliers are now investing in bioplastics, recycled plastics, and other sustainable materials that reduce environmental impact while maintaining performance standards. By incorporating these materials into their production processes, automotive parts manufacturers can significantly lower their carbon footprint and appeal to environmentally conscious consumers.

Moreover, advancements in material science have made it possible to create high-performance plastics from renewable resources without compromising quality or durability. This shift not only helps reduce reliance on fossil fuels but also promotes a circular economy where waste is minimized and resources are reused effectively. As more auto parts manufacturers adopt these eco-friendly materials, they contribute to a greener future while enhancing their brand reputation.

The Role of Plastic Manufacturers in Sustainability

Plastic manufacturers play a pivotal role in the quest for sustainability within the automotive industry. By prioritizing environmentally friendly practices throughout their operations, these companies can help mitigate the negative effects associated with traditional plastic production methods. From sourcing raw materials responsibly to implementing energy-efficient processes and reducing waste, automotive plastics suppliers have the power to influence significant change.

Additionally, collaboration among plastic manufacturers and automotive parts manufacturers is essential for driving innovation toward sustainable solutions. Joint efforts can lead to the development of new technologies that enhance recyclability and promote the use of alternative materials. As these partnerships flourish, they will not only benefit individual companies but also foster an industry-wide commitment to sustainability.

Innovations Towards Green Manufacturing

Innovations are at the forefront of transforming how automotive manufacturing approaches sustainability through green practices. Emerging technologies such as additive manufacturing (3D printing) offer exciting opportunities for reducing material waste while allowing greater design flexibility for auto parts manufacturers. These advancements enable companies to produce components on-demand rather than maintaining large inventories that may go unsold or unused.

Moreover, many leading automotive plastics suppliers are exploring closed-loop systems where end-of-life products are collected and recycled back into new components—effectively creating a circular economy model within the industry. Such innovations not only minimize environmental impact but also enhance supply chain efficiency by reducing dependency on virgin materials sourced from non-renewable resources.

As we look ahead at trends shaping sustainable practices in automotive manufacturing, it’s clear that both innovation and collaboration will be critical drivers of success—ensuring that today’s advancements lead us toward a cleaner tomorrow.

Future Trends in Automotive Injection Molding

The landscape of automotive injection molding is evolving rapidly, driven by technological advancements and changing market demands. As automotive manufacturers seek to enhance efficiency and sustainability, the role of automotive plastics suppliers becomes increasingly critical. In this section, we explore the future trends that are shaping the industry and how auto parts manufacturers can adapt.

Advancements in Mold Design Technologies

One of the most exciting developments in automotive injection molding is the advancement in mold design technologies. Innovations such as 3D printing for mold prototypes allow for quicker iterations and reduced lead times, enabling automotive parts manufacturers to bring products to market faster than ever before. Additionally, smart mold technologies equipped with sensors are being integrated into production processes, enhancing precision and reducing waste during manufacturing.

These advancements not only streamline operations but also improve product quality, which is paramount for automotive plastics suppliers striving to meet stringent industry standards. The ability to create complex geometries with high accuracy means that auto parts manufacturers can produce lighter components without compromising strength or durability. This evolution in mold design will likely lead to a new era of innovation within the automotive manufacturing sector.

The Impact of Electric Vehicles on Auto Parts Suppliers

The rise of electric vehicles (EVs) is reshaping the landscape for auto parts manufacturers and their supply chains. As automakers pivot towards EV production, there’s an increasing demand for lightweight materials that enhance battery efficiency and overall vehicle performance—this is where innovative solutions from automotive plastics suppliers come into play. The shift from traditional internal combustion engines to electric drivetrains necessitates a reevaluation of existing components and opens up opportunities for new designs using advanced polymers.

Moreover, electric vehicles often require unique cooling systems and battery housings made from specialized plastic materials that can withstand high temperatures while remaining lightweight. This shift presents both challenges and opportunities for plastic manufacturers who must adapt their offerings accordingly to meet evolving specifications from OEMs (Original Equipment Manufacturers). As a result, collaboration between auto parts manufacturers and their material suppliers will be crucial in driving forward this transformation in the automotive manufacturing industry.

Predictions for the Automotive Manufacturing Landscape

Looking ahead, several predictions can be made about the future of automotive injection molding within an ever-evolving manufacturing landscape. First off, we expect a greater emphasis on sustainability as consumers become more environmentally conscious; thus, eco-friendly materials will gain traction among automotive plastics suppliers aiming to capture this growing market segment. Companies that prioritize sustainable practices are likely to stand out as leaders among their peers.

Additionally, automation and smart manufacturing techniques will continue to rise in prominence within auto parts manufacturers' operations—enhancing productivity while minimizing human error through robotics and AI-driven processes. Finally, we anticipate increased collaboration between various stakeholders across the supply chain as companies seek integrated solutions that leverage cutting-edge technologies like IoT (Internet of Things) for real-time monitoring and optimization.

Conclusion

In the fast-paced world of automotive manufacturing, selecting the right suppliers is crucial for success. Automotive plastics suppliers play a pivotal role in ensuring that auto parts manufacturers can deliver high-quality products efficiently and sustainably. As the industry evolves, understanding how to choose these partners wisely will be key to maintaining a competitive edge.

Key Takeaways on Choosing Suppliers

When evaluating automotive plastics suppliers, consider their experience and reputation in the market. Look for automotive parts manufacturers who prioritize quality assurance, as this can significantly impact your production line's efficiency and reliability. Additionally, assessing their technological capabilities can provide insights into how well they can meet your specific needs in automotive manufacturing.

The Importance of Quality and Innovation

Quality is non-negotiable in the realm of auto parts manufacturing; subpar materials can lead to costly recalls and damage to brand reputation. Innovative practices among plastic manufacturers not only enhance product performance but also contribute to sustainable practices within the industry. Embracing new technologies and methodologies ensures that automotive plastics suppliers remain relevant and competitive in an ever-evolving market.

Looking Ahead in Automotive Parts Manufacturing

The future of automotive manufacturing looks promising with advancements like electric vehicles reshaping supplier relationships and material requirements. As we move forward, it’s essential for automotive parts manufacturers to stay ahead of trends such as lightweight materials and eco-friendly solutions offered by progressive plastic manufacturers. By keeping an eye on these developments, businesses can adapt swiftly, ensuring longevity in a dynamic landscape.