Introduction

In the fast-evolving landscape of medical technology, the significance of medical micro molding cannot be overstated. This specialized form of injection molding allows for the production of intricate and precise components essential for modern medical devices. As healthcare demands grow, so does the need for innovative solutions in mold manufacture that meet stringent industry standards.

Understanding Mini and Micro Molding

Mini and micro molding are techniques that enable manufacturers to create small, high-precision parts with exceptional detail. In medical molding, these processes are crucial for producing components such as syringes, connectors, and implants that require exact specifications. The ability to mold tiny products efficiently not only enhances functionality but also contributes to overall patient safety.

Importance in the Medical Sector

The importance of injection molded parts in the medical sector cannot be overlooked; they play a vital role in ensuring that devices function correctly and safely. Medical devices often require complex geometries that traditional manufacturing methods struggle to achieve, making micro molding an invaluable asset. Furthermore, with advancements in technology, manufacturers can now produce these critical components at a scale and speed that meets the ever-increasing demand.

Innovations in Injection Molding

Innovation is at the heart of injection molding advancements, particularly within the realm of medical applications. New materials and techniques are being developed to improve biocompatibility and performance while reducing production costs and timeframes. These innovations not only streamline processes but also enhance product quality, making it easier for companies to deliver reliable moulding products tailored for healthcare needs.

Overview of Medical Micro Molding

Medical micro molding is at the forefront of innovation in the healthcare industry, enabling the production of intricate and precise components essential for modern medical devices. This specialized form of injection molding focuses on creating tiny, complex parts that meet stringent regulatory standards while ensuring high performance and reliability. The evolution of medical molding technologies continues to push boundaries, leading to advancements in patient care and treatment options.

Key Technologies in Medical Molding

In the realm of medical micro molding, several key technologies play a pivotal role in shaping injection molded parts with unmatched precision. Techniques such as multi-material injection molding allow for the integration of different materials within a single part, enhancing functionality without compromising quality. Additionally, advancements in automated mold manufacture streamline production processes, resulting in faster turnaround times and reduced costs while maintaining exceptional standards.

Unique Challenges in Molding Medical Parts

Molding medical parts presents unique challenges that require specialized knowledge and expertise to overcome. One significant hurdle is ensuring biocompatibility; materials must not only meet stringent safety regulations but also perform reliably within the human body over extended periods. Furthermore, achieving precision during the molding process is critical—any deviation can lead to part failure or compromised patient safety, highlighting the importance of rigorous quality control measures throughout the entire manufacturing process.

Applications Across Medical Devices

The applications of medical micro molding are vast and varied, spanning numerous types of medical devices that enhance patient outcomes significantly. From surgical instruments to drug delivery systems, injection molded parts are integral to devices like catheters and implants where precision is paramount. As healthcare technology continues to evolve, so does the demand for innovative solutions through advanced medical molding techniques that cater specifically to these critical applications.

The Role of Injection Molding

Injection molding is a cornerstone technique in the manufacturing of medical devices, particularly when it comes to medical micro molding. This process allows for the creation of intricate, high-precision components that are essential for modern healthcare applications. By leveraging the benefits of injection molded parts, manufacturers can meet stringent industry standards while optimizing production efficiency.

Benefits of Injection Molded Parts

One of the standout benefits of injection molded parts is their ability to produce complex geometries with remarkable consistency. In medical molding, this capability translates into highly detailed components that can fit seamlessly into various medical devices. Additionally, injection molding allows for rapid production cycles, enabling manufacturers to meet urgent market demands without compromising quality.

Another advantage lies in material versatility; a wide range of biocompatible materials can be used in medical micro molding processes. This flexibility ensures that products not only meet performance requirements but also adhere to regulatory standards for safety and efficacy. Ultimately, these benefits culminate in cost-effective solutions that enhance patient care through reliable and innovative medical products.

Precision and Accuracy in Production

Precision is paramount when it comes to manufacturing components for the medical sector, where even the slightest deviation can have significant consequences. Injection molding excels in this regard by providing exceptional accuracy during production runs, ensuring that each part meets exact specifications consistently over time. This level of precision is particularly critical in applications such as surgical instruments and implantable devices.

Moreover, advancements in mold manufacture technology have further enhanced the precision achievable through injection molding techniques. With innovations like multi-cavity molds and advanced cooling systems, manufacturers are now able to produce large quantities of identical parts with minimal variation—a game-changer for mass production scenarios in medical applications. As a result, companies can maintain high levels of efficiency while delivering top-notch quality across their product lines.

Case Studies in Medical Applications

To illustrate the impact of injection molded parts within the realm of medical applications, let's take a closer look at a couple of notable case studies. One prominent example involves a leading manufacturer specializing in insulin delivery systems; they utilized advanced injection molding techniques to create precise microfluidic components that improved drug delivery accuracy and patient outcomes significantly.

Another compelling case study comes from an organization focused on developing prosthetic devices; they leveraged custom molds designed through cutting-edge software to produce lightweight yet durable prosthetic limbs tailored to individual patient needs. The use of injection molded parts not only streamlined their production process but also enhanced overall product performance—demonstrating how effective medical micro molding can revolutionize healthcare solutions.

Ultimately, these case studies underscore how crucial injection molding is within the landscape of modern medicine—showcasing its ability to deliver innovative solutions while maintaining rigorous standards necessary for patient safety and satisfaction.

The Process of Molding Medical Parts

The process of molding medical parts is a carefully orchestrated series of steps that ensures precision and reliability. From the initial design to the final product, each phase plays a crucial role in producing high-quality injection molded parts tailored for medical applications. Understanding these steps is essential for anyone involved in medical micro molding.

Steps in Mould Manufacture

The journey begins with the conceptualization and design of the mold, where engineers utilize advanced software to create intricate designs that cater to specific medical needs. Once the design is finalized, manufacturing begins with selecting appropriate materials that can withstand rigorous sterilization processes while maintaining biocompatibility. Following this, precision machining techniques are employed to create molds that ensure tight tolerances—essential for effective injection molding and the production of reliable medical components.

After machining, the mold undergoes assembly and testing to guarantee optimal performance during production runs. Any necessary adjustments are made at this stage, ensuring that every detail aligns perfectly with specifications before moving forward. Finally, once testing confirms functionality and quality standards are met, mass production can commence using advanced injection molding techniques.

Quality Control Measures

Quality control measures in medical molding are paramount due to the critical nature of healthcare products. Rigorous testing protocols are implemented at every stage—from material selection through final inspection—to ensure compliance with industry standards and regulations. Techniques such as statistical process control (SPC) monitor production processes continuously, allowing for immediate detection and correction of any deviations from quality benchmarks.

Moreover, validation procedures confirm that each batch of injection molded parts meets stringent requirements for safety and efficacy before reaching end-users or healthcare providers. This commitment to quality not only protects patients but also reinforces trust in manufacturers who prioritize excellence in their products. Regular audits and certifications further bolster confidence by demonstrating adherence to international quality standards.

Innovations in Tooling and Design

Innovations in tooling and design have revolutionized the landscape of molding medical parts, enhancing efficiency while reducing costs associated with traditional methods. Advanced materials like hardened steel or aluminum alloys improve durability while facilitating complex geometries required for intricate devices used in healthcare settings. Furthermore, rapid prototyping technologies enable designers to quickly iterate on mold designs based on real-time feedback from production trials.

Additionally, integrating smart technology into molds allows for real-time monitoring during injection molding processes—leading to enhanced accuracy and reduced waste throughout production cycles. These innovations not only streamline operations but also contribute significantly to sustainability efforts within the industry by minimizing resource consumption during manufacturing phases. As a result, companies can produce high-quality medical components more efficiently than ever before.

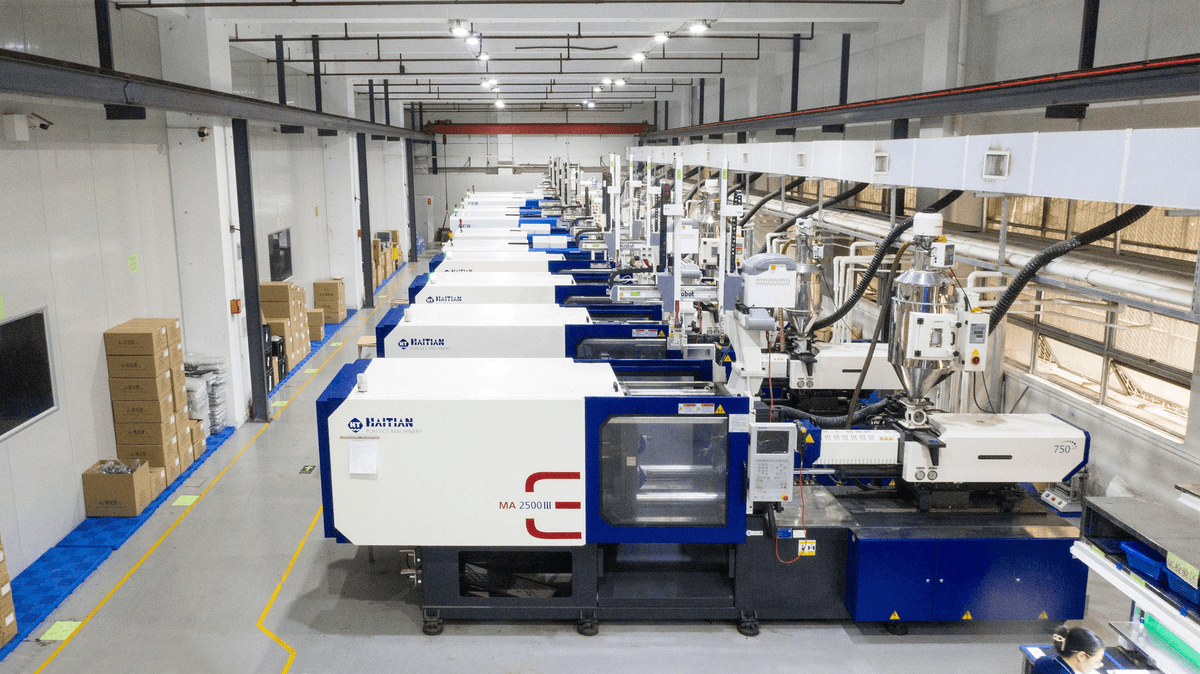

Baoyuan's Expertise in Molding Medical

When it comes to medical micro molding, Baoyuan stands out as a leader in the industry. With a focus on precision and innovation, the company has honed its capabilities in injection molding to cater specifically to the rigorous demands of medical applications. This expertise not only ensures high-quality products but also reinforces Baoyuan’s reputation as a trusted partner in the realm of medical molding.

Senior Management and Technical Proficiency

At Baoyuan, senior management brings a wealth of experience and technical proficiency that is crucial for molding medical parts. Their deep understanding of both the market and technological advancements allows them to navigate unique challenges associated with medical micro molding effectively. This leadership ensures that every aspect of mold manufacture adheres to stringent industry standards while fostering an environment where continuous improvement is paramount.

Advanced Software for Mold Design

Baoyuan leverages advanced software tools for mold design, enhancing the efficiency and accuracy of their injection molded parts. These cutting-edge technologies enable precise simulations and optimizations during the design phase, reducing lead times significantly without compromising quality. By integrating sophisticated software into their processes, Baoyuan can produce intricate designs that meet complex specifications required in medical molding.

Quality Assurance in Production

Rigorous testing protocols are implemented at every stage—from initial design through to final production—to ensure that each injection molded part meets high safety and performance standards. This unwavering commitment to quality not only safeguards patient health but also builds trust among clients seeking reliable partners for their medical molding needs.

Future Trends in Medical Micro Molding

The landscape of medical micro molding is evolving rapidly, driven by innovation and the need for high-quality, precise components. As the demand for smaller, more effective medical devices grows, so too does the importance of advancements in injection molding technologies. This section delves into the future trends shaping the world of medical molding.

Biocompatibility and Material Innovations

In medical micro molding, biocompatibility is paramount; materials must not only be safe but also effective in their applications. The development of new polymers that meet stringent regulatory requirements while offering enhanced performance characteristics is critical. Innovations such as bioresorbable materials are paving the way for more efficient injection molded parts that can safely dissolve after fulfilling their function within the body.

Moreover, advancements in material science are leading to the creation of composites that improve strength without compromising weight or flexibility—key attributes for many medical devices. This trend toward specialized materials supports a broader range of applications in medical molding, from surgical instruments to drug delivery systems. As manufacturers invest in research and development, we anticipate a surge in novel material options tailored specifically for use in injection molded parts.

Sustainable Practices in Molding Medical

Sustainability has become a cornerstone principle across industries, and medical micro molding is no exception. The push towards eco-friendly practices involves using recycled materials and reducing waste during mold manufacture processes to minimize environmental impact. By adopting sustainable practices, companies can not only improve their carbon footprint but also appeal to increasingly environmentally-conscious consumers.

Additionally, energy-efficient machinery and production techniques are being implemented to reduce resource consumption during manufacturing processes. These innovations ensure that while producing high-quality molding products, manufacturers remain committed to sustainability principles that resonate with both regulatory bodies and customers alike. As this trend continues to grow, we can expect an even greater emphasis on sustainability within medical molding operations.

The Impact of 3D Printing on Injection Molding

The rise of 3D printing technology has started to influence traditional methods like injection molding significantly. While injection molded parts have long been favored for their precision and scalability, 3D printing offers rapid prototyping capabilities that allow designers to iterate quickly without extensive costs tied up in mold manufacture processes. This synergy between 3D printing and traditional methods opens new avenues for innovation within the realm of medical micro molding.

Furthermore, combining these two technologies enables manufacturers to create complex geometries previously deemed impossible with conventional molding techniques alone. As a result, we may see an increase in customized solutions tailored specifically for individual patient needs—a game changer for personalized medicine approaches! In this ever-evolving landscape where technology meets healthcare demands, understanding how these trends interconnect will be crucial for stakeholders involved in molding medical products.

Conclusion

In the rapidly evolving landscape of healthcare, the significance of medical micro molding cannot be overstated. This specialized form of injection molding plays a pivotal role in producing intricate components for medical devices, ensuring precision and reliability where it matters most. As we navigate the complexities of modern medicine, the need for high-quality injection molded parts becomes increasingly apparent.

The Significance of Medical Micro Molding

Medical micro molding is crucial in creating components that meet stringent industry regulations while maintaining high performance standards. These tiny yet vital parts are essential in various applications, from surgical instruments to diagnostic equipment, demonstrating how even the smallest elements can make a significant impact on patient care. By leveraging advanced techniques in medical molding, manufacturers can produce reliable and consistent products that enhance overall healthcare outcomes.

Advancements in Injection Molding Technology

The advancements in injection molding technology have revolutionized how we approach mold manufacture and design for medical applications. With innovations such as enhanced automation and real-time monitoring systems, manufacturers can achieve unprecedented levels of precision and efficiency when creating injection molded parts. These technological strides not only improve production timelines but also reduce waste and costs associated with traditional molding methods, making them more sustainable.

Choosing the Right Partner for Medical Molding

A knowledgeable partner will bring expertise in both technical proficiency and quality assurance processes to ensure that your projects meet regulatory requirements without compromising on quality or innovation. Ultimately, collaborating with an experienced provider specializing in medical micro molding can elevate your product line while ensuring safety and efficacy for end-users.