Introduction

In the ever-evolving landscape of manufacturing, the injection molding process stands out as a cornerstone for producing high-quality components, especially in the medical field. Medical injection molding suppliers play a crucial role in this domain, providing specialized services that transform innovative ideas into reliable products using advanced plastic injection molding techniques. Understanding how this process works is essential for anyone looking to delve into the world of mold plastic injection and its myriad applications.

Understanding the Injection Molding Process

Injection molding is a manufacturing technique that involves injecting molten material—usually thermoplastics—into a pre-designed mold to create specific shapes and products. This method is particularly effective for creating intricate designs and high-volume production runs, making it ideal for medical device manufacturing. By utilizing injection moldable plastics, manufacturers can achieve precise tolerances and consistent quality across thousands of units.

Importance of Choosing Quality Suppliers

Choosing quality medical injection molding suppliers is paramount to ensuring product reliability and compliance with stringent industry standards. The right supplier not only brings expertise in plastic molding but also offers insights into technological advancements that can enhance product performance. A partnership with reputable plastic injection molding companies can significantly impact time-to-market and overall project success.

Overview of Top Medical Injection Molding Suppliers

The market boasts several leading medical injection molding suppliers known for their innovation, versatility, and commitment to quality assurance. Companies such as Baoyuan, Kaysun Corporation, and Accumold are at the forefront of this sector, each bringing unique strengths to the table—from precision micro-molding techniques to extensive customization capabilities in plastic injection molding molds. Exploring these top players provides valuable insights into how they can meet diverse needs within the medical industry.

Factors to Consider in Medical Injection Molding

When selecting a medical injection molding supplier, several critical factors come into play that can significantly influence the quality and efficiency of your production process. Understanding these factors will help you make informed decisions that align with your project needs and compliance requirements. By focusing on quality assurance, technological capabilities, and robust customer support, you can ensure a seamless partnership with plastic injection molding companies.

Quality Assurance and Certifications

Quality assurance is paramount in the realm of medical injection molding; after all, you're dealing with products that could directly impact patient safety. Suppliers should possess relevant certifications such as ISO 13485, which demonstrates their commitment to maintaining high standards in manufacturing processes specific to medical devices. Additionally, look for companies that implement rigorous testing protocols for their injection moldable plastics to guarantee consistency and reliability throughout production.

Technological Capabilities and Innovations

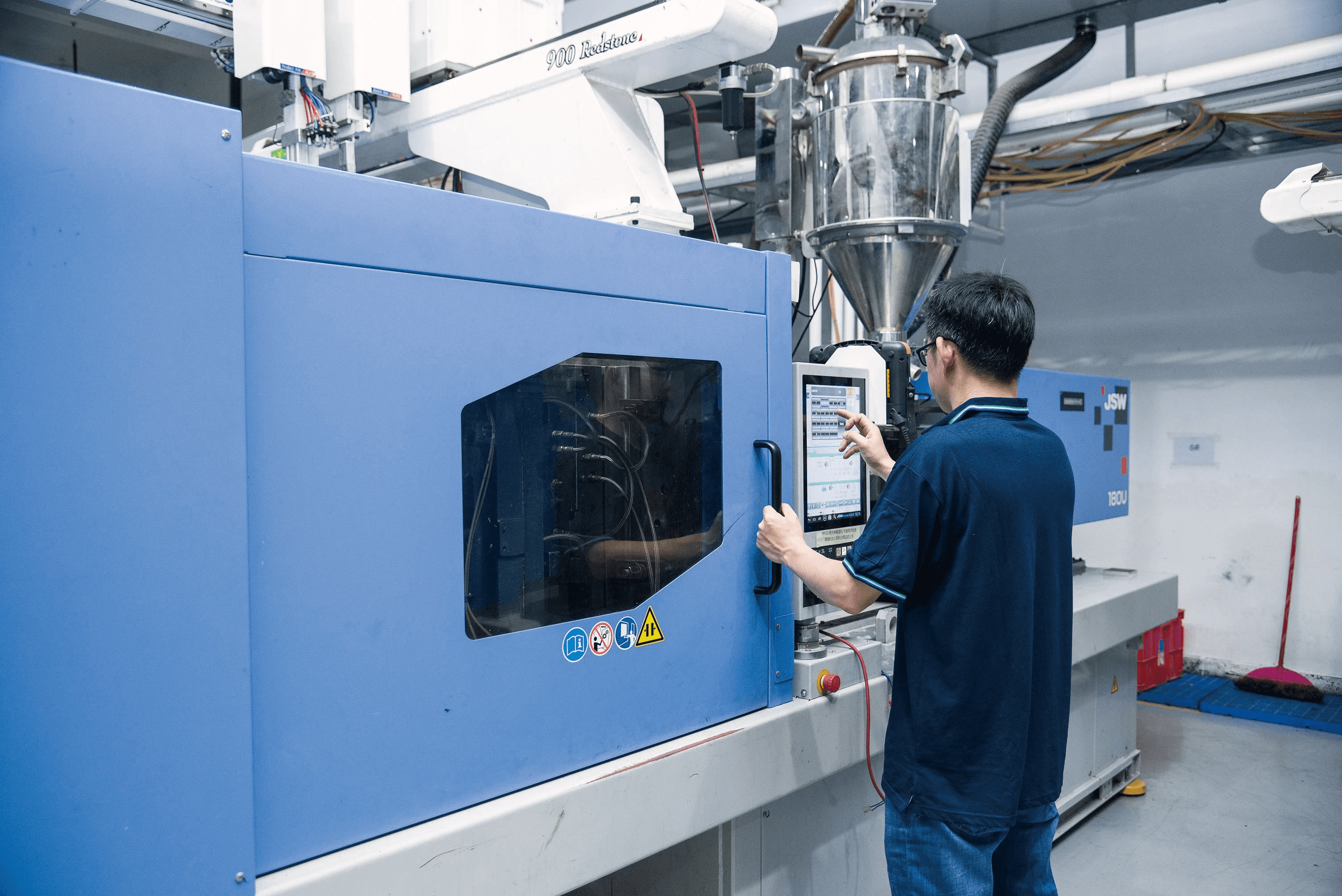

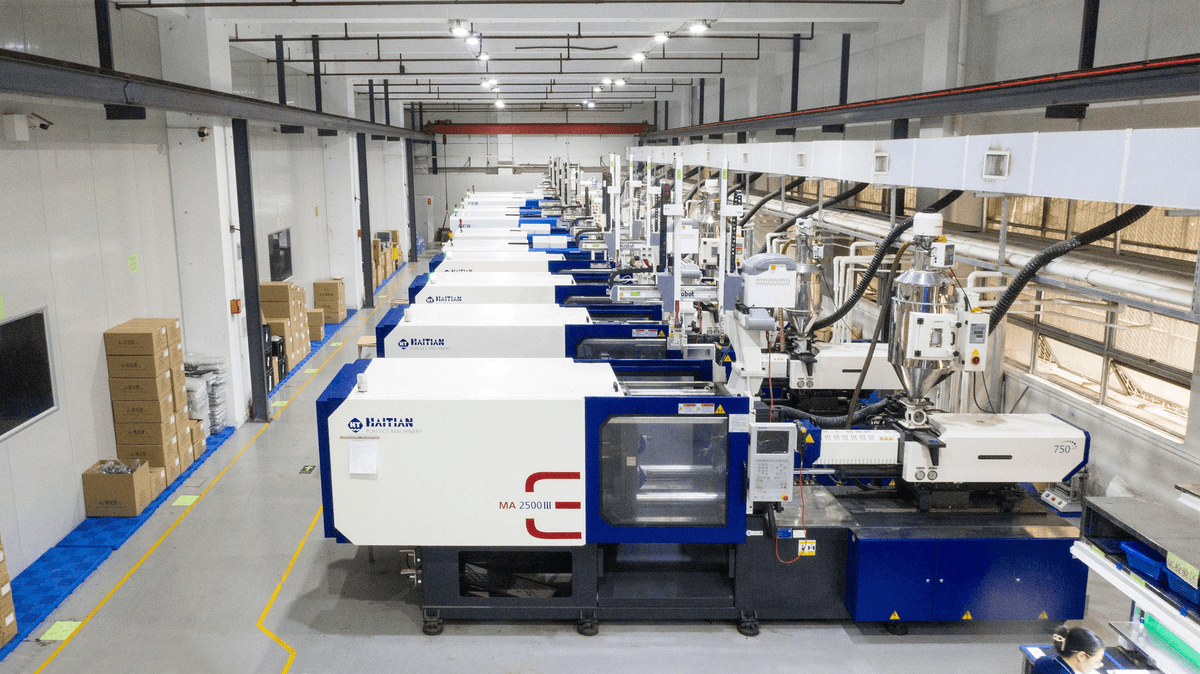

In an industry where precision is key, the technological capabilities of your chosen plastic injection molding supplier can set them apart from the competition. Suppliers equipped with advanced machinery and innovative techniques can produce intricate designs using mold plastic injection methods that enhance product functionality while reducing waste. Furthermore, keeping an eye on emerging technologies allows you to partner with forward-thinking companies that continuously improve their processes through automation and smart manufacturing practices.

Customer Support and Communication

Effective communication is the backbone of any successful partnership with medical injection molding suppliers. A supplier who prioritizes customer support will not only respond promptly but also provide valuable insights during the design phase of your project, ensuring your specifications are met without hiccups along the way. Moreover, building a strong rapport fosters trust; when challenges arise during production or delivery, having clear lines of communication makes problem-solving much smoother.

Leading Medical Injection Molding Suppliers

Baoyuan: Expertise and Innovation

Baoyuan has carved a niche as a frontrunner among medical injection molding suppliers by marrying expertise with innovation. They specialize in creating advanced injection moldable plastics tailored for the medical sector, showcasing their commitment to quality and precision. Their state-of-the-art plastic injection molding processes ensure that every component meets rigorous safety standards while maintaining cost efficiency.

Moreover, Baoyuan’s focus on continuous improvement allows them to stay ahead of industry trends, making them a preferred choice for companies looking to innovate within their product lines. With an impressive portfolio of successful projects, they have demonstrated an ability to handle complex designs and customizations in mold plastic injection efficiently. Partnering with Baoyuan means access to cutting-edge technology and unparalleled support throughout the entire production process.

Niche Specialties of Injection Molding Companies

Medical Device Manufacturing Expertise

Medical device manufacturing is a highly specialized field within injection molding. Suppliers who focus on this niche have honed their skills to produce intricate components that meet stringent safety and efficacy standards. Their deep understanding of injection moldable plastics allows them to create reliable products essential for healthcare applications, from syringes to surgical instruments.

In addition to technical capabilities, these suppliers often invest heavily in research and development to stay ahead of industry trends. This commitment ensures that they can offer innovative solutions tailored specifically for medical applications. Consequently, partnering with experienced plastic injection molding companies can significantly enhance product quality and performance.

Moreover, expertise in this area also means familiarity with various materials suitable for medical use—everything from biocompatible plastics to sterilizable options. As you evaluate potential suppliers, consider their track record in producing high-quality medical devices that adhere strictly to industry regulations.

Customization Capabilities in Plastic Injection Molding

Customization is another vital specialty among leading plastic injection molding companies. The ability to tailor products according to client specifications can lead to enhanced functionality and improved patient outcomes. Whether it's altering dimensions or integrating unique features into the mold plastic injection process, flexibility is key.

Many medical professionals require bespoke solutions that off-the-shelf products simply cannot provide; thus, having a supplier adept at customization becomes invaluable. These companies utilize advanced technologies like 3D printing and computer-aided design (CAD) software during the initial stages of product development—allowing for rapid prototyping and adjustments before full-scale production begins.

Ultimately, superior customization capabilities not only improve the end product but also foster collaborative relationships between clients and suppliers. By working closely together on designs and innovations, both parties can achieve better results while ensuring compliance with necessary regulations throughout the process.

Compliance with Regulatory Standards

Compliance with regulatory standards is non-negotiable when selecting a partner among medical injection molding suppliers. The healthcare sector is governed by strict guidelines set forth by organizations like the FDA (Food and Drug Administration) or ISO (International Organization for Standardization). Suppliers must demonstrate an unwavering commitment to quality assurance processes that guarantee their products meet these rigorous requirements.

A reputable plastic injection molding company will have established protocols for testing materials and finished goods alike—ensuring they are safe for patient use while minimizing risks associated with manufacturing defects or contamination issues during production runs. This diligence not only protects patients but also safeguards your brand's reputation against potential liabilities stemming from non-compliance.

Furthermore, many top-tier suppliers maintain certifications reflecting their adherence to these standards—providing peace of mind as you navigate your project’s complexities within this tightly regulated environment. By prioritizing compliance when choosing an injection moldable plastics supplier, you position yourself for long-term success in delivering high-quality healthcare solutions.

Benefits of Using Specialized Plastic Injection Molding

By leveraging the expertise of top-tier medical injection molding suppliers, companies can ensure that their products meet stringent industry standards while also benefiting from advanced manufacturing techniques. The advantages are numerous, ranging from enhanced product quality to significant cost efficiencies and quicker market entry.

Enhanced Product Quality and Durability

One of the standout benefits of utilizing specialized plastic injection molding is the remarkable enhancement in product quality and durability. Medical injection molding suppliers employ high-precision processes that ensure every component is crafted with exceptional accuracy, minimizing defects and maximizing reliability. Additionally, the use of advanced injection moldable plastics allows for greater strength and resilience in end products, which is particularly vital in medical applications where safety cannot be compromised.

Cost Efficiency in Production

Cost efficiency is another compelling reason to choose specialized plastic injection molding services. With optimized production processes provided by leading plastic injection molding companies, manufacturers can reduce waste and lower material costs while still maintaining high-quality standards. Furthermore, the scalability of these operations means that as demand increases, production can ramp up without incurring significant additional expenses—making it a smart financial decision for businesses looking to thrive in a competitive market.

Faster Time-to-Market for Products

In today's fast-paced medical industry, getting products to market quickly can be a game-changer for businesses. Specialized plastic molding techniques enable rapid prototyping and efficient production cycles, allowing companies to bring their innovations to life faster than ever before. This speed not only helps maintain competitive advantage but also ensures that critical medical solutions are available when they are needed most—ultimately improving patient outcomes.

Comparing Medical Injection Molding Suppliers

When it comes to selecting medical injection molding suppliers, performance evaluation is crucial. Supplier performance can be assessed through various metrics such as production efficiency, defect rates, and adherence to delivery schedules. A reliable supplier should not only meet your immediate needs but also demonstrate a commitment to continuous improvement in their injection molding processes.

Evaluating Supplier Performance

To effectively evaluate the performance of plastic injection molding companies, you should consider their track record in quality assurance and innovation. Metrics like on-time delivery rates and customer satisfaction scores are essential for understanding how well a supplier operates under pressure. Additionally, reviewing their technological capabilities can provide insights into how they handle complex projects involving injection moldable plastics.

A key factor in evaluating supplier performance is their ability to adapt to changing project requirements without compromising quality. For example, if you need a specific type of mold plastic injection that requires advanced techniques or materials, the supplier's flexibility will be tested. The best medical injection molding suppliers will have robust systems in place for monitoring and improving their operational efficiency.

Reviews and Testimonials from Clients

Client reviews and testimonials serve as valuable resources when comparing different plastic molding suppliers. Positive feedback from previous customers often reflects the reliability and expertise of the company in delivering high-quality products on time. Look for testimonials that specifically mention experiences with medical device manufacturing or custom plastic injection molding projects.

Moreover, consider seeking out third-party review platforms where clients share unfiltered opinions about their experiences with these companies. This information can help you gauge how well a supplier meets its promises regarding product quality and customer service. If possible, reach out directly to past clients for firsthand accounts of working with particular medical injection molding suppliers.

Pricing Structures and Cost Analysis

Understanding pricing structures is essential when evaluating potential partners among plastic injection molding companies. Different suppliers may offer varying cost models based on factors such as volume discounts or tooling fees associated with custom molds for plastic injection molding projects. Conducting a thorough cost analysis will help you determine which options provide the best value without sacrificing quality.

Be wary of choosing suppliers solely based on price; sometimes lower costs may indicate compromises in material quality or production capabilities that could affect your final product's integrity. It's wise to request detailed quotes that break down all associated costs—this transparency allows you to compare apples to apples when assessing different medical injection molding suppliers' offerings. Ultimately, balancing cost with quality assurance will lead you toward making an informed decision that aligns with your project goals.

Conclusion

In the world of medical injection molding, selecting the right suppliers is crucial for ensuring quality and compliance. The choice of medical injection molding suppliers can significantly impact product outcomes, from safety to performance. By focusing on key factors such as certifications, technological capabilities, and customer support, businesses can make informed decisions that lead to successful partnerships.

Key Takeaways for Selecting Suppliers

When evaluating potential plastic injection molding companies, it's essential to prioritize quality assurance and relevant certifications. Look for suppliers that specialize in injection moldable plastics designed specifically for medical applications; this ensures adherence to stringent regulatory standards. Additionally, consider their technological capabilities—innovative solutions in mold plastic injection can enhance product efficiency and reliability.

Enhancing Quality through Expert Partnerships

Partnering with specialized plastic molding companies can elevate the quality of your products significantly. These experts bring a wealth of experience in medical device manufacturing and customization capabilities in plastic injection molding that are hard to match. By collaborating with proficient medical injection molding suppliers, businesses not only improve product durability but also streamline their production processes.

Future Trends in Medical Injection Molding

The landscape of plastic injection molding is ever-evolving, with new technologies shaping the future of manufacturing in the medical sector. Expect advancements in automation and smart manufacturing practices among leading medical injection molding suppliers, which will drive efficiencies and reduce time-to-market for critical products. As demand for high-quality healthcare solutions increases, staying ahead of these trends will be vital for companies looking to thrive in this competitive environment.