Introduction

In the realm of healthcare, precision is paramount, and medical injection molding stands at the forefront of this necessity. This specialized form of plastic injection molding focuses on creating high-quality components that meet stringent regulatory standards. By utilizing advanced techniques and equipment, manufacturers can mold plastic injection products that are essential for various medical applications.

What is Medical Injection Molding

Medical injection molding is a manufacturing process used to produce precise plastic components for the healthcare industry. It involves injecting molten plastic into a mold to create intricate shapes and designs tailored for medical devices and tools. This method allows for the efficient production of items ranging from syringes to surgical instruments, ensuring consistency in quality and performance.

Importance of Precision in Medical Manufacturing

Precision in medical manufacturing cannot be overstated; even the slightest deviation can lead to significant consequences in patient care. Medical injection molding ensures that every component produced meets exact specifications, which is crucial for safety and efficacy in medical devices. As a result, manufacturers rely heavily on injection moldable plastics that offer reliable performance under strict standards.

Overview of Common Applications

The applications of medical injection molding span a wide range of products vital to healthcare delivery. Common uses include the production of diagnostic equipment parts, drug delivery systems like inhalers or auto-injectors, and various disposable items such as gloves or tubing connectors. Each application highlights how versatile plastic molding can be while still adhering to rigorous quality protocols necessary for patient safety.

The Process of Medical Injection Molding

Medical injection molding is a sophisticated process that transforms raw plastic materials into precise components essential for healthcare applications. Understanding this process is crucial for anyone involved in medical manufacturing, as it ensures that products meet stringent quality and safety standards. Let’s dive into the nitty-gritty of how plastic injection molding works.

Step-by-Step Breakdown

The journey of creating a molded plastic component begins with designing the mold, which serves as the blueprint for the final product. Once the design is finalized, the selected injection moldable plastics are melted down and injected into the mold under high pressure, allowing them to fill every nook and cranny of the cavity. After cooling, the mold opens to release the finished part, which undergoes further inspection and testing to ensure it meets all necessary specifications.

This step-by-step breakdown highlights how precision plays a pivotal role in medical injection molding; even minor deviations can lead to compromised product integrity. The entire process is often automated to enhance efficiency while maintaining quality control, making it ideal for high-volume production runs typical in medical manufacturing. By following these steps meticulously, manufacturers can produce components ranging from syringes to intricate surgical instruments with remarkable accuracy.

Key Materials in Plastic Injection Molding

Commonly used materials include polypropylene (PP), polycarbonate (PC), and polyethylene (PE), each offering unique properties that cater to specific needs within healthcare settings. For instance, PP is favored for its chemical resistance and durability, while PC provides exceptional clarity and strength.

Biocompatibility is another critical consideration; materials must not cause adverse reactions when they come into contact with biological tissues or fluids. This requirement narrows down options significantly but ensures that only safe injection moldable plastics are utilized in producing medical devices and components. Ultimately, selecting appropriate materials directly impacts both performance and compliance with regulatory standards governing medical manufacturing.

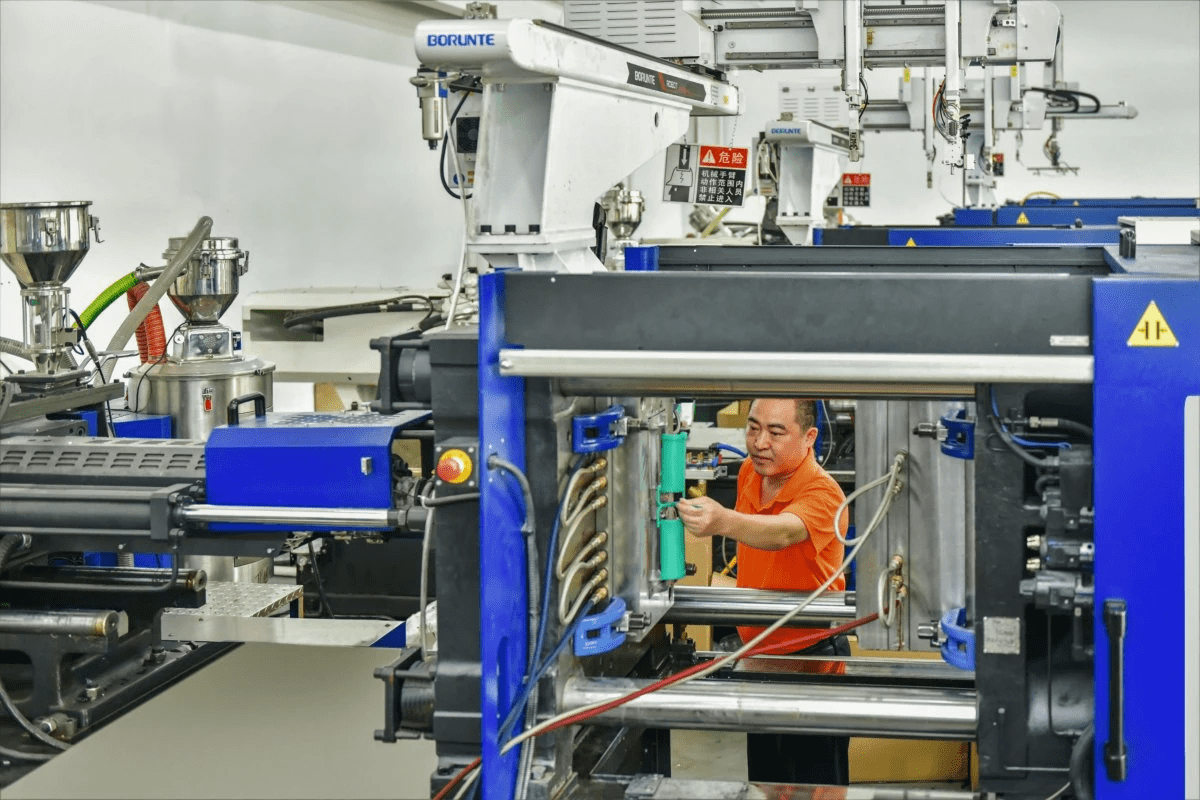

The Role of Injection Molding Equipment

Injection molding equipment plays an indispensable role in ensuring efficient production processes within medical manufacturing environments. High-quality machines designed specifically for plastic molding provide consistent temperature control and precise pressure application during each cycle—key factors that influence part quality significantly. Additionally, advancements in technology have led to more energy-efficient equipment that reduces waste while maintaining output levels.

Modern injection molding machines often incorporate automation features that enhance speed without sacrificing accuracy; this is particularly important when dealing with high-stakes products like surgical tools or drug delivery systems where precision cannot be compromised. Furthermore, ongoing innovations in equipment design enable manufacturers to adapt quickly to changing market demands or new material formulations without overhauling their entire production line.

Advantages of Using Medical Injection Molding

When it comes to medical manufacturing, the advantages of medical injection molding are hard to ignore. This process not only enhances efficiency but also ensures that the products meet stringent industry standards. Let’s dive into the key benefits that make it a preferred choice for manufacturers.

Cost-Effectiveness in Production

One of the most compelling reasons for utilizing medical injection molding is its cost-effectiveness in production. By streamlining the manufacturing process, companies can significantly reduce labor costs and material waste, leading to lower overall expenses. Additionally, once the initial mold plastic injection is created, producing large quantities becomes economical due to reduced per-unit costs, making it a savvy investment for businesses.

High Precision and Consistency

Precision is paramount in medical manufacturing, and plastic injection molding delivers just that. The ability to create intricate designs with high accuracy means that each component produced meets exact specifications consistently over time. This high level of precision minimizes errors and ensures that products function reliably—an absolute necessity when dealing with healthcare applications where patient safety is at stake.

Flexibility with Injection Moldable Plastics

Another advantage of using medical injection molding lies in its flexibility with injection moldable plastics. Manufacturers can choose from a variety of materials tailored to specific applications, whether they need biocompatible options or durable plastics resistant to sterilization processes. This versatility allows for innovation in product design while meeting diverse regulatory requirements in the medical field.

Considerations for Selecting Injection Moldable Plastics

When it comes to medical injection molding, selecting the right injection moldable plastics is crucial. The materials chosen not only affect the performance and safety of the final products but also influence production efficiency and costs. Understanding the key considerations, such as biocompatibility, durability, and cost implications, can make all the difference in medical manufacturing.

Biocompatibility Requirements

Biocompatibility is a non-negotiable factor in the realm of medical injection molding. Any plastic used must be compatible with biological tissues to prevent adverse reactions when in contact with patients. This means that manufacturers often turn to specialized materials that meet stringent regulatory standards, ensuring that their mold plastic injection processes yield safe and effective products.

Selecting biocompatible plastics involves a thorough understanding of both material properties and testing protocols. Not all plastics are created equal; some may leach harmful substances or degrade over time when exposed to bodily fluids or sterilization processes. Therefore, investing time in research and development to find suitable injection moldable plastics is essential for maintaining high safety standards in medical manufacturing.

Durability and Strength

Durability and strength are paramount when choosing materials for plastic injection molding in healthcare applications. Medical devices often face rigorous handling conditions, so selecting robust plastics can greatly enhance product longevity and reliability. High-strength materials reduce the risk of breakage or failure during use, ensuring patient safety while also minimizing costly recalls or replacements.

Moreover, durable plastics are critical for products used in demanding environments such as surgical instruments or implantable devices. These applications require materials that can withstand high temperatures during sterilization without losing structural integrity or performance characteristics over time. Therefore, manufacturers must prioritize durability alongside other factors like weight and flexibility when evaluating potential injection moldable plastics.

Impact on Production Costs

The choice of injection moldable plastics significantly impacts production costs within medical manufacturing processes. While high-quality materials might come with a higher upfront price tag, they can lead to savings down the line through reduced waste and improved efficiency during plastic molding operations. Manufacturers need to carefully balance material costs against potential benefits such as enhanced product performance and compliance with regulatory standards.

Additionally, certain polymers may facilitate faster cycle times due to their processing characteristics—an essential consideration for maximizing productivity within production schedules dominated by tight deadlines in healthcare settings. This means that while cheaper options might seem appealing initially, they could ultimately lead to increased expenses due to slower processing times or higher defect rates during production runs involving medical injection molding equipment.

In conclusion, careful consideration of biocompatibility requirements, durability needs, and cost implications plays a vital role in selecting suitable injection moldable plastics for medical applications—ensuring both patient safety and operational efficiency remain at the forefront of medical manufacturing practices.

Quality Assurance in Medical Manufacturing

Quality assurance is the backbone of medical manufacturing, particularly when it comes to medical injection molding. The stakes are high, as even minor defects can lead to significant consequences in healthcare settings. Rigid quality control processes ensure that every product meets stringent regulatory standards and patient safety requirements.

Importance of Rigid Quality Control

In medical injection molding, rigid quality control is essential for maintaining the integrity of products used in patient care. This industry demands precision; a tiny variation in mold plastic injection can result in a faulty device that may compromise patient safety or treatment efficacy. Therefore, implementing robust quality assurance protocols not only safeguards patients but also enhances trust among healthcare providers and manufacturers alike.

Techniques for Ensuring Product Integrity

To ensure product integrity in plastic injection molding, various techniques are employed throughout the manufacturing process. These include regular inspections of injection molding equipment, rigorous testing of raw materials, and adherence to standardized operating procedures (SOPs). Additionally, advanced technologies like automated inspection systems help identify defects early on, ensuring that only top-quality injection moldable plastics make it through to production.

The Role of the Baoyuan Team in Quality Assurance

The Baoyuan team plays a pivotal role in upholding quality assurance standards within medical manufacturing processes. Their expertise ensures that every aspect of medical injection molding—from material selection to final inspection—is executed with precision and care. By leveraging their knowledge and experience, they contribute significantly to producing reliable plastic molding solutions that meet both industry regulations and customer expectations.

Future Trends in Medical Injection Molding

The landscape of medical injection molding is rapidly evolving, driven by constant innovations and the need for more efficient production methods. As the healthcare industry demands higher precision and quality, advancements in materials and technologies are reshaping how plastic injection molding is approached. This section will explore the exciting future trends that promise to enhance medical manufacturing practices.

Innovations in Materials and Technologies

In recent years, there has been a significant focus on developing advanced injection moldable plastics that meet stringent biocompatibility requirements while enhancing durability. New materials such as bio-based plastics and high-performance thermoplastics are emerging, providing not only better performance but also reducing environmental impact. Moreover, innovations in processing technologies, such as multi-component injection molding, allow manufacturers to create complex parts with varying properties all within a single production cycle.

These cutting-edge materials and technologies are setting new standards for medical injection molding applications like surgical instruments, drug delivery systems, and diagnostic devices. As a result, manufacturers can produce components that not only meet regulatory standards but also offer improved functionality and patient safety. The ongoing research into smart materials—those that can respond to external stimuli—could revolutionize how we think about plastic molding in the medical field.

Sustainability in Plastic Molding

Sustainability is no longer just a buzzword; it's becoming a critical consideration in plastic manufacturing processes worldwide. The push for eco-friendly practices has led to increased interest in recyclable materials and sustainable sourcing of raw materials used in medical injection molding. Companies are now exploring biodegradable plastics that can decompose after their useful life cycle, significantly reducing waste associated with traditional plastic products.

Furthermore, advancements in recycling technologies are enabling manufacturers to reuse scrap material generated during the mold plastic injection process effectively. By adopting these sustainable practices within their production lines, organizations not only contribute positively to environmental conservation but also appeal to increasingly eco-conscious consumers and healthcare providers alike. Ultimately, sustainability initiatives will play a pivotal role in shaping the future of plastic molding within the medical sector.

The Impact of Automation on Production

Automation is transforming every aspect of production—and medical injection molding is no exception. With smart factories on the rise, automated systems can enhance efficiency by streamlining workflows while minimizing human error during manufacturing processes. Sophisticated robotics integrated with advanced injection molding equipment can handle intricate tasks such as part assembly or inspection at speeds previously thought impossible.

This shift towards automation allows companies engaged in medical manufacturing to scale operations without sacrificing quality or precision—a crucial advantage when producing life-saving devices or components where consistency is paramount. Moreover, data analytics generated from automated systems provide valuable insights into production performance metrics enabling continuous improvement strategies for both efficiency and product integrity over time.

Conclusion

In summary, medical injection molding stands as a cornerstone of modern medical manufacturing, offering unparalleled precision and efficiency. The benefits of plastic injection molding are manifold, including cost-effectiveness, high consistency, and flexibility in design. As healthcare continues to evolve, the role of injection moldable plastics will only grow more significant in creating reliable and innovative medical devices.

Recap of Medical Injection Molding Benefits

The principal advantages of medical injection molding are its ability to produce intricate designs with high levels of accuracy. This technique allows manufacturers to create components that meet stringent biocompatibility standards while maintaining durability through the use of specialized injection moldable plastics. Furthermore, the cost-effectiveness achieved through optimized production processes makes it an attractive option for companies looking to balance quality with budget constraints.

Challenges in Medical Manufacturing

Despite its many benefits, medical manufacturing faces several challenges that require careful navigation. Regulatory compliance is a prominent hurdle; manufacturers must ensure their products adhere strictly to safety standards and regulations governing healthcare materials. Additionally, sourcing reliable suppliers for quality injection molding equipment can be daunting, as the market demands both innovation and reliability in plastic molding technologies.

The Future of Injection Molding in Healthcare

Looking ahead, the future of medical injection molding appears bright with exciting innovations on the horizon. Advancements in materials science promise more biocompatible options that enhance patient safety while reducing environmental impact through sustainable practices in plastic molding. Moreover, automation is set to revolutionize production lines, increasing efficiency and consistency while minimizing human error—an essential factor in maintaining high standards in medical manufacturing.