Introduction

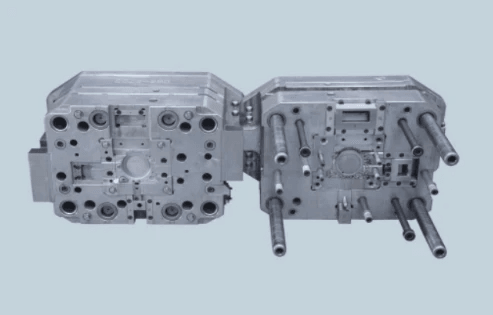

The Basics of Mold Creation

Mold creation is an essential step in producing high-quality plastic products, serving as the foundation for various manufacturing processes. At its core, mold making involves designing and constructing a cavity into which molten material is injected, allowing it to cool and solidify into the desired shape. Understanding these basics helps businesses appreciate why investing in quality molds can lead to significant long-term benefits.

Key Factors Influencing Costs

The costs associated with creating molds can vary significantly based on several key factors, including design complexity and material choices. For instance, intricate designs may require more advanced techniques and materials, driving up expenses. Additionally, choosing between local and international plastic injection molding services can also impact overall costs due to shipping fees and potential tariffs.

The Role of Plastic Injection Molding

Plastic injection molding stands out as one of the most efficient methods for producing high volumes of parts with precision and consistency. It involves injecting molten plastic into a mold cavity under pressure, which allows for rapid production cycles while maintaining tight tolerances on dimensions. As companies consider their options in injection casting or other methods, understanding how plastic injection molding can optimize production efficiency becomes increasingly important.

Understanding Plastic Injection Molding

Plastic injection molding is a transformative process that has revolutionized the manufacturing landscape. It allows for the mass production of intricate plastic parts with remarkable precision and efficiency. But before diving into the details, let’s unpack what this process entails.

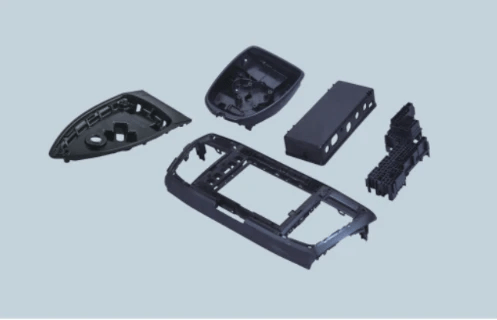

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing technique where molten plastic is injected into a mold to create specific shapes and designs. This method is favored for its ability to produce high volumes of identical parts quickly, making it ideal for everything from automotive components to consumer goods. When considering how much does it cost to make a mold for plastic, it's essential to factor in the initial setup and long-term production benefits.

Types of Injection Moldable Plastics

There’s a smorgasbord of materials available for injection molding, each offering unique properties suited for various applications. Common types include thermoplastics like ABS, polypropylene, and polycarbonate, which are known for their versatility and durability. Additionally, engineers often explore specialized injection moldable plastics that can withstand extreme conditions or offer enhanced aesthetic qualities.

Advantages of Injection Molding Process

One of the standout benefits of the injection molding process is its efficiency—once the mold is created, producing thousands of parts becomes a breeze! This method not only minimizes waste but also ensures consistent quality across batches, making it an attractive option for businesses looking at plastic injection molding services. Moreover, while upfront costs might make you ponder how much does it cost to make a mold for plastic, in the long run, durable molds lead to significant savings by reducing material waste and maximizing production efficiency.

Cost Breakdown of Mold Creation

When diving into the world of mold creation, it's essential to understand the various costs involved. From initial design to material expenses and labor overhead, each element plays a crucial role in determining how much it ultimately costs to make a mold for plastic. This breakdown will help you navigate the financial landscape of plastic injection molding services.

Initial Design and Prototyping Costs

The journey begins with the initial design and prototyping phase, which can significantly impact the overall cost of injection molding. This stage involves creating detailed CAD models and prototypes that serve as blueprints for your mold. Depending on complexity, these design services can range from a few hundred to several thousand dollars, making it vital to choose a reliable plastic injection moulding service that understands your vision.

Prototyping is not just about aesthetics; it's about functionality too. Investing in high-quality prototypes can save you money down the line by identifying potential issues before committing to production molds. So while upfront costs may seem steep, they are often justified by avoiding costly errors later in the injection casting process.

Material Expenses for Mold Making

Next on our cost breakdown is material expenses for mold making—an area where costs can vary widely based on selected materials and specifications. The type of steel or aluminum used for molds can significantly affect durability and performance, which directly correlates with how much does it cost to make a mold for plastic. For instance, high-grade steel may have a higher upfront cost but offers longevity that cheaper materials cannot match.

In addition to metal choice, you'll also need to consider any additional coatings or treatments that enhance wear resistance or reduce friction during production runs with injection moldable plastics. These factors contribute not only to immediate costs but also long-term savings through increased efficiency and reduced maintenance needs over time in your plastic injection molding services.

Labor and Overhead Costs

Labor and overhead costs are often overlooked when calculating how much it costs to make a mold for plastic but are crucial components nonetheless. Skilled technicians are needed at every stage—from designing CAD models to machining molds—which naturally leads to varying labor rates based on expertise required for each task involved in plastic injection molding services.

Additionally, overhead encompasses everything from facility rent and utilities to equipment maintenance—factors that accumulate over time but should be factored into your overall budget planning for injection molding projects. Understanding these hidden costs helps businesses make informed decisions when selecting their preferred plastic injection moulding service provider while ensuring they get quality without breaking the bank.

Factors Affecting Mold Costs

When it comes to understanding how much it costs to make a mold for plastic, several key factors come into play. These elements can significantly influence the overall expense of the mold creation process, especially in the context of plastic injection molding services. By grasping these factors, businesses can make informed decisions and potentially save on costs.

Complexity of the Mold Design

The complexity of the mold design is one of the most significant determinants of cost in injection molding. Intricate designs often require more advanced techniques and materials, which can drive up expenses considerably. For instance, molds with complex geometries or multiple cavities necessitate precise engineering and higher-quality materials, leading to increased costs when using a plastic injection moulding service.

Moreover, if you’re considering custom designs for your injection molds, be prepared for additional fees associated with prototyping and testing. The more detailed your design is, the more time and resources will be needed to bring it to life in the form of injection casting or other methods. Ultimately, simplifying your mold design could lead to significant savings while still achieving functional results with injection moldable plastics.

Size and Scale of Production

Another critical factor influencing how much it costs to make a mold for plastic is the size and scale of production intended for that mold. Larger molds typically require more material and labor to create, which naturally increases overall costs. Additionally, if you plan on producing high volumes of parts using a single mold, investing in higher-quality materials may be worthwhile despite initial expenses.

On the other hand, smaller-scale productions may benefit from simpler molds that are less expensive but could compromise quality over time. It’s essential to strike a balance between size requirements and production goals when selecting a plastic injection molding service provider. This decision will ultimately impact not only upfront costs but also long-term efficiency in production runs.

Use of Advanced Technologies

The use of advanced technologies can significantly affect both initial investment and long-term savings when creating molds for plastic products. Innovative techniques such as 3D printing or computer-aided design (CAD) allow for rapid prototyping and precision engineering that traditional methods might not achieve as efficiently or accurately. While these technologies may come with higher upfront costs initially, they often lead to better quality molds with fewer defects over time.

Moreover, utilizing advanced technologies can streamline processes like injection casting by reducing lead times and minimizing waste during production runs—factors that are crucial when considering how much it costs to make a mold for plastic parts effectively. In an industry where precision is paramount, opting for modern solutions can offer substantial returns on investment through enhanced productivity levels within your manufacturing process.

Comparing Plastic Injection Molding Services

When it comes to selecting plastic injection molding services, the choice between local and international providers can significantly impact your project’s outcome and budget. Understanding the pros and cons of each option is essential, especially when considering how much it costs to make a mold for plastic. Local providers may offer quicker turnaround times and easier communication, while international companies might provide lower costs due to economies of scale.

Exploring Local vs. International Providers

Local plastic injection moulding service providers often boast an intimate understanding of regional market needs, which can lead to more tailored solutions for your specific requirements. However, they may come at a premium price compared to their international counterparts who can leverage lower labor costs abroad. On the flip side, choosing an international provider could save you money on initial mold creation costs but might introduce complexities in logistics and communication that could offset those savings.

In addition to cost considerations, think about quality control when deciding between local and international suppliers for injection molding services. While many international companies maintain high standards, working with a local provider often allows for easier oversight during the production process. Ultimately, weighing these factors will help you decide which route aligns best with your project goals.

Quality Assurance in Mold Production

Quality assurance is paramount in the world of plastic injection molding; after all, a poorly made mold can lead to costly mistakes down the line. When evaluating different providers, ensure they have robust quality control measures in place throughout the entire production process—from design through final inspection. Look for certifications or industry standards that indicate a commitment to producing high-quality molds that meet your specifications.

Additionally, consider how each supplier handles potential defects or issues during production; proactive measures can save you time and money later on by preventing wasteful rework or recalls due to faulty products made from subpar molds. Investing in reliable quality assurance not only enhances product consistency but also contributes positively towards understanding how much it costs to make a mold for plastic effectively over time.

Ultimately, choosing a provider with strong quality assurance practices will give you peace of mind that your investment in plastic injection molding will yield durable and efficient results.

Baoyuan's Expertise in Mold Making

Baoyuan stands out as a leader among plastic injection molding service providers thanks to its extensive experience and commitment to excellence in mold making. With years of expertise under their belt, Baoyuan ensures precision at every stage of the process—whether you're exploring initial design concepts or delving into advanced materials like injection moldable plastics. Their knowledgeable team works closely with clients from start to finish, making them an ideal partner if you're wondering how much it costs to make a mold for plastic without compromising on quality.

What sets Baoyuan apart is their ability to utilize cutting-edge technologies alongside traditional craftsmanship methods—ensuring that every molded piece is produced efficiently while maintaining durability over time. This blend of innovation and skill allows clients not only access competitive pricing but also confidence in long-term savings derived from investing in superior molds designed specifically for their needs.

Choosing Baoyuan means placing your project into capable hands where expertise meets affordability—making them an excellent option when considering various plastic injection molding services available today.

Long-Term Savings with Quality Molds

Investing in high-quality molds can lead to significant long-term savings for businesses engaged in plastic injection molding. When you consider how much it costs to make a mold for plastic, the initial investment may seem daunting. However, the precision and durability of quality molds can drastically reduce production costs over time, making them a wise choice for any manufacturer looking to optimize their operations.

Importance of Precision in Injection Molding

Precision is paramount in the world of injection molding; even the smallest deviation can result in defects that compromise product quality. High-quality molds ensure that every component produced meets exact specifications, minimizing the need for costly rework or scrap materials. This accuracy not only enhances product reliability but also boosts customer satisfaction, ultimately contributing to a more robust bottom line.

Reducing Waste and Maximizing Efficiency

One of the most significant benefits of investing in superior plastic injection molding services is waste reduction. Quality molds are designed to maximize efficiency by ensuring optimal material usage and minimizing excess scrap during production runs. By reducing waste, companies can lower their overall material expenses—an essential consideration when calculating how much it costs to make a mold for plastic.

Cost-Effectiveness of Durable Molds

Durability is another critical factor influencing long-term savings when it comes to mold creation. High-quality injection moldable plastics are engineered to withstand repeated cycles without losing integrity or performance over time. This longevity means fewer replacements and repairs, translating into substantial cost savings that make premium mold investments worthwhile.

Conclusion

In the world of plastic injection molding, understanding the total investment required for mold creation is crucial for any business looking to enter or expand in this market. The costs associated with making a mold for plastic can vary significantly based on several factors, including design complexity and production scale. By evaluating these expenses carefully, businesses can better allocate their budgets and ensure that they are making sound financial decisions.

Evaluating Total Investment for Mold Creation

When considering how much it costs to make a mold for plastic, it’s essential to look beyond just the initial outlay. The total investment encompasses not only the upfront costs of design and prototyping but also long-term expenses related to material selection and maintenance over time. Understanding these elements helps businesses gauge whether opting for a more expensive yet durable mold could lead to savings down the line.

Making Informed Decisions with Costs

Making informed decisions about plastic injection molding services requires a thorough grasp of all associated costs. By comparing various plastic injection moulding service providers, companies can find options that align with their budget while still meeting quality standards. Additionally, knowing how much does it cost to make a mold for plastic allows companies to weigh their options effectively—whether it's investing in higher-quality molds or seeking more economical alternatives.

The Future of Plastic Injection Molding

The future of plastic injection molding looks promising as advancements in technology continue to enhance efficiency and reduce waste in production processes. Innovations such as 3D printing and smart manufacturing are likely to influence how injection casting is approached, potentially lowering costs further while maintaining high-quality standards in mold production. As businesses adapt to these changes, understanding the nuances of injection moldable plastics will be key in staying competitive within this evolving landscape.