Introduction

In the intricate world of manufacturing, the significance of gates in injection molding cannot be overstated. These small but mighty components play a pivotal role in determining the quality and efficiency of molded products. From understanding what a gate is in injection molding to recognizing its impact on production outcomes, this introduction sets the stage for a deeper exploration into various gate types and their applications.

Understanding the Importance of Gates

Gates serve as entry points for molten plastic during the injection molding process, and their design can greatly influence the final product's characteristics. A poorly designed gate can lead to defects such as uneven flow or unsightly gate marks in injection molding, which can diminish product appeal and functionality. It's essential to grasp how different gates affect not only aesthetics but also operational efficiency in manufacturing.

Exploring Injection Molding Basics

At its core, injection molding is a method used to create parts by injecting molten material into a mold. This process involves several critical components, including the hopper, screw, barrel, and yes—gates! Understanding these basics lays a solid foundation for appreciating how various gates function within this sophisticated system.

Types of Gates and Their Uses

There are several types of gates used in injection molding, each with unique benefits tailored to specific applications. For instance, some gates enhance precision while others focus on reducing waste or improving seal integrity—like those found in gate seal injection molding systems. Familiarizing oneself with these options allows manufacturers to select the most suitable type for their needs while minimizing issues like plastic injection molding gate blush that can arise from improper selection.

The Mysterious Edge Gate

When diving into the world of injection molding, understanding the role of different gates is crucial. Among these, edge gates stand out for their unique features and applications. They not only serve as entry points for molten plastic but also leave behind a characteristic mark known as a gate mark in injection molding.

What is a gate mark in injection molding?

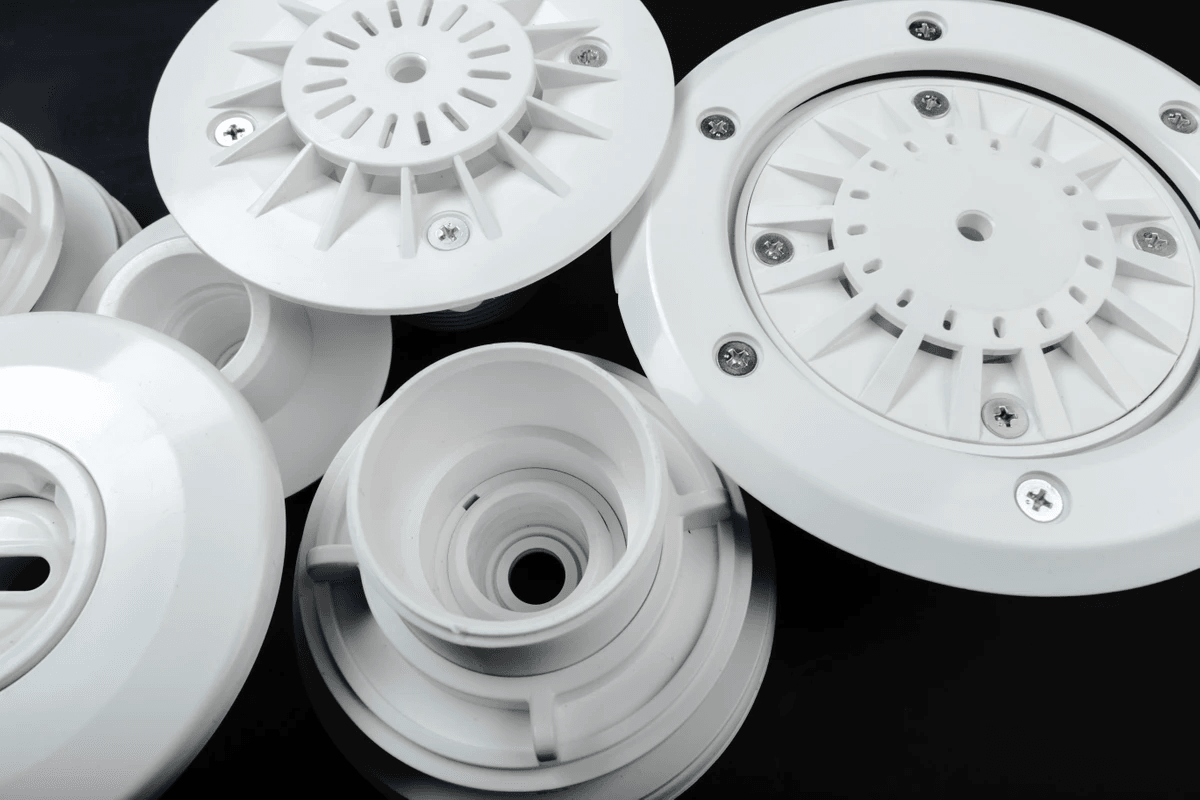

A gate mark in injection molding refers to the visible trace left on a molded part where the molten plastic entered during production. This mark can vary in appearance depending on several factors, including the type of gate used and the material properties of the plastic. Understanding what is a gate mark in injection molding helps manufacturers evaluate part aesthetics and structural integrity, making it an essential consideration during design.

The presence of a gate mark can sometimes be seen as an imperfection; however, with proper design and placement, it can be minimized or even strategically utilized for aesthetic purposes. So when pondering what is the gate in injection molding, remember that it’s not just about functionality but also about how these marks affect product appeal. In some cases, innovative approaches can lead to designs that cleverly incorporate or hide these marks.

Benefits of Edge Gates in Production

Edge gates offer several benefits that make them popular among manufacturers engaged in turnkey injection molding processes. One major advantage is their ability to facilitate quick filling of molds while maintaining consistent pressure throughout production—essential for achieving high-quality parts without defects like sink marks or voids. Moreover, edge gates typically require less material than other types of gates, which translates to reduced costs and waste.

Another key benefit lies in their ease of removal post-production; this means fewer complications during secondary operations like trimming or finishing. With fewer steps involved after demolding, manufacturers can streamline their processes further—an attractive prospect when considering overall efficiency and productivity gains within any operation focused on plastic injection molding gate blush reduction efforts.

Applications in the Industry

Edge gates are versatile and find applications across various industries due to their distinct advantages and characteristics. They are commonly used for producing thin-walled parts where precision is essential—think consumer electronics housings or automotive components requiring high-performance standards without compromising weight or durability.

Additionally, industries such as medical device manufacturing leverage edge gates for applications where cleanliness and precision are paramount; here, every detail counts! The ability to control flow rates effectively makes edge gates ideal candidates for complex designs often seen within turnkey injection molding projects aimed at delivering quality products efficiently.

In summary, understanding edge gates opens up new avenues for improving production techniques while addressing aesthetic concerns tied to gate marks—ultimately contributing positively towards advancing mold technology across various sectors.

The Versatile Submarine Gate

Submarine gates are an innovative solution in the world of injection molding, offering a unique approach to managing flow and aesthetics. Unlike traditional gates, these cleverly designed openings are submerged beneath the part surface, which helps conceal any potential gate marks in the final product. This not only enhances the visual appeal but also provides manufacturers with a reliable method for achieving high-quality finishes without compromising structural integrity.

Advantages of Submarine Gates

One of the primary advantages of submarine gates is their ability to minimize gate mark injection molding issues. By placing the gate below the surface, any visible blemishes are effectively hidden from view, allowing for a cleaner appearance that is often required in consumer products. Additionally, submarine gates facilitate better control over material flow and cooling rates, which can lead to improved dimensional accuracy and reduced cycle times.

Another benefit is their versatility; submarine gates can be used across various materials and part geometries, making them suitable for both simple and complex designs. They also tend to reduce waste by optimizing material usage during production processes—an attractive feature for manufacturers looking to streamline operations and cut costs. Ultimately, these advantages make submarine gates a popular choice in turnkey injection molding applications.

When to Use Submarine Gates

Submarine gates shine in scenarios where aesthetics are paramount or where part geometry presents challenges for traditional gating methods. If your project demands a flawless finish without visible gate marks in injection molding, opting for a submarine gate is often the best route to take. They work particularly well with large surface areas or intricate designs where other gate types may struggle with flow consistency or leave unsightly blemishes.

Another key consideration is material type; certain resins benefit from the controlled flow characteristics provided by submarine gates—especially those prone to warping or shrinkage during cooling phases. Therefore, when planning your next plastic injection molding project, evaluate whether your design would benefit from this innovative solution based on its specific requirements.

Impact on Gate Seal Injection Molding

When discussing what is gate seal injection molding, it's essential to recognize how submarine gates influence this process significantly. The submerged nature of these gates creates an effective seal during injection cycles that minimizes leakage risks while maintaining consistent pressure throughout the cavity filling phase. This enhanced sealing capability directly contributes to producing parts with fewer defects and higher overall quality.

Moreover, using submarine gates can help mitigate issues associated with plastic injection molding gate blush—a common concern when dealing with visible imperfections caused by improper cooling or uneven material distribution at conventional gating sites. By ensuring smooth transitions between materials and reducing turbulence within the cavity during filling processes, manufacturers can achieve superior results without compromising efficiency or increasing production costs.

In summary, incorporating submarine gates into your manufacturing strategy not only elevates product aesthetics but also optimizes functional performance through improved sealing techniques during injection cycles.

The Reliable Hot Runner Gate

When it comes to the realm of injection molding, the hot runner gate stands out as a reliable choice for many manufacturers. This technology utilizes heated channels to keep plastic in a molten state, allowing for quick and efficient production cycles. Understanding how hot runner systems function is essential for anyone looking to optimize their molding processes.

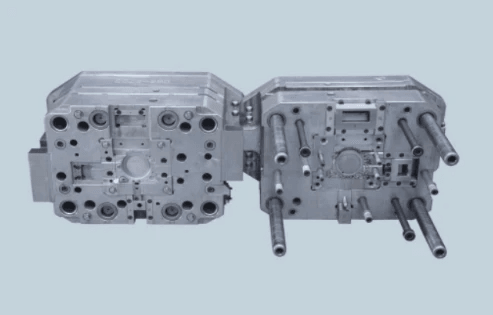

How Hot Runner Technology Works

Hot runner technology operates by maintaining the temperature of the plastic material throughout its journey from the injection unit to the mold cavity. Unlike cold runners, which allow material to cool and solidify before being injected into the mold, hot runners keep everything warm and flowing smoothly. This method not only speeds up production but also minimizes waste—a significant advantage in high-volume manufacturing environments.

Reducing Waste in Production

One of the standout benefits of using hot runner gates is their ability to significantly reduce waste in production processes. Traditional systems often result in excess plastic that must be trimmed away—resulting in what is known as a gate mark in injection molding on finished products. With hot runners, manufacturers can achieve near-zero waste levels since there’s no need for additional trimming or recycling of leftover materials.

Perfecting the Plastic Injection Molding Gate Blush

The phenomenon known as gate blush can be a bane for many manufacturers, leading to unsightly marks on finished products that can affect aesthetics and functionality. However, with precise control offered by hot runner gates, achieving a flawless finish becomes much more feasible. By minimizing pressure fluctuations during injection—often responsible for creating these imperfections—hot runners help ensure that your products not only meet quality standards but also enhance overall customer satisfaction.

The Innovative Valve Gate

When it comes to precision and efficiency in injection molding, the valve gate is a game changer. This innovative gate type allows for controlled flow of molten plastic into the mold, significantly reducing waste and improving part quality. Understanding its functionality helps manufacturers optimize their processes and products.

Functionality of Valve Gates

Valve gates operate by utilizing a pin mechanism that opens and closes the flow of plastic into the mold cavity. This control not only minimizes the risk of overfilling but also reduces the occurrence of gate marks in injection molding, which can be unsightly on finished products. Essentially, what is a gate in injection molding? It's a crucial component that ensures precise material delivery while maintaining high-quality standards.

The ability to manage when and how plastic enters the mold means that valve gates are particularly effective for complex shapes or parts with varying wall thicknesses. By enabling better control over material flow, manufacturers can achieve more consistent results across production runs. Moreover, this functionality translates into fewer defects and less need for post-processing work on molded parts.

Enhancing Precision in Molding

The precision offered by valve gates plays a vital role in producing high-quality components with minimal imperfections. With their design focused on controlling melt flow, these gates help prevent issues like short shots or excessive flashing around the edges—common problems encountered with other gate types. Consequently, understanding what is gate seal injection molding becomes essential; it involves ensuring that seals are tight without compromising part integrity.

In addition to preventing defects, valve gates facilitate intricate designs that require exact measurements and tolerances. This capability enhances overall product performance while streamlining manufacturing processes—it's a win-win situation! By reducing variability in how materials are injected into molds, manufacturers can confidently produce components that meet stringent industry standards.

Common Applications in Turnkey Injection Molding

Valve gates find widespread use across various industries due to their adaptability and efficiency in production settings known as turnkey injection molding solutions. These applications range from automotive components to consumer electronics where precision is paramount for functionality and aesthetics alike. In these sectors, achieving minimal Plastic Injection Molding Gate Blush becomes critical for maintaining visual appeal without sacrificing performance.

Another area where valve gates shine is when dealing with multi-cavity molds; they allow for uniform filling across all cavities simultaneously—no more waiting around! This not only speeds up production times but also ensures consistency among parts produced within the same cycle. The versatility of valve gates makes them an ideal choice for manufacturers looking to enhance productivity while minimizing costs associated with defects or rework.

The Practical Cold Runner Gate

Cold runner systems are a clever approach in the world of injection molding, allowing for efficient material flow without the added heat. In these systems, the runner that delivers molten plastic to the molds is kept at a lower temperature, which means that it solidifies after the part has been formed. This method not only conserves energy but also simplifies the recycling process since any leftover material can be easily reprocessed and reused.

Understanding Cold Runner Systems

To grasp how cold runner systems work, it's essential to know what a gate is in injection molding. The gate serves as the entry point for molten plastic into the mold cavity and plays a crucial role in controlling flow and pressure during production. By utilizing a cold runner system, manufacturers can achieve more uniform filling patterns while minimizing waste—essentially setting themselves up for success right from the start.

Cost-Effective Solutions for Manufacturers

One of the standout benefits of cold runner systems is their cost-effectiveness for manufacturers. Since they reduce material waste and allow for easier recycling, companies can significantly decrease their overhead costs while maintaining high-quality outputs. Additionally, cold runners often require less maintenance than their hot counterparts because there’s no need to manage temperature fluctuations—making them an attractive option in turnkey injection molding projects.

Relationship to Gate Mark Injection Molding

Now, let’s connect this all back to gate mark injection molding—a term that might pique your interest! When we talk about what is a gate mark in injection molding, we're referring to those little blemishes left on parts where molten plastic enters through the gate. In cold runner systems, these marks tend to be less pronounced compared to other types of gates due to better control over flow dynamics and cooling times; thus enhancing overall aesthetics while ensuring functional integrity.

Conclusion

In the intricate world of injection molding, selecting the right gate type can significantly impact both production efficiency and product quality. Whether you’re grappling with what is a gate mark in injection molding or pondering the nuances of gate seal injection molding, understanding these elements is crucial. Ultimately, the choice of gate can make or break your project, influencing everything from waste reduction to aesthetic finish.

Choosing the Right Gate Type

Choosing the right gate type is akin to picking the perfect ingredient for your favorite recipe; it can elevate your end product from mundane to magnificent. Each gate type—be it edge, submarine, hot runner, valve, or cold runner—comes with distinct advantages and applications that cater to specific needs in plastic injection molding. By understanding what is a gate in injection molding and how various gates function, manufacturers can optimize their processes and achieve superior results.

Importance of Gate Design in Production

The design of a gate plays a pivotal role in determining not just the efficiency but also the quality of molded products. A well-thought-out design minimizes issues like plastic injection molding gate blush and ensures uniform flow throughout the mold cavity. Moreover, recognizing what is a gate mark in injection molding allows manufacturers to refine their designs further and mitigate potential defects before they arise.

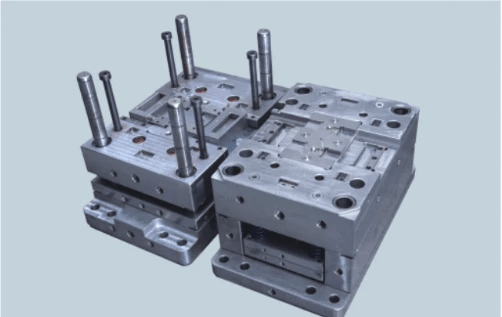

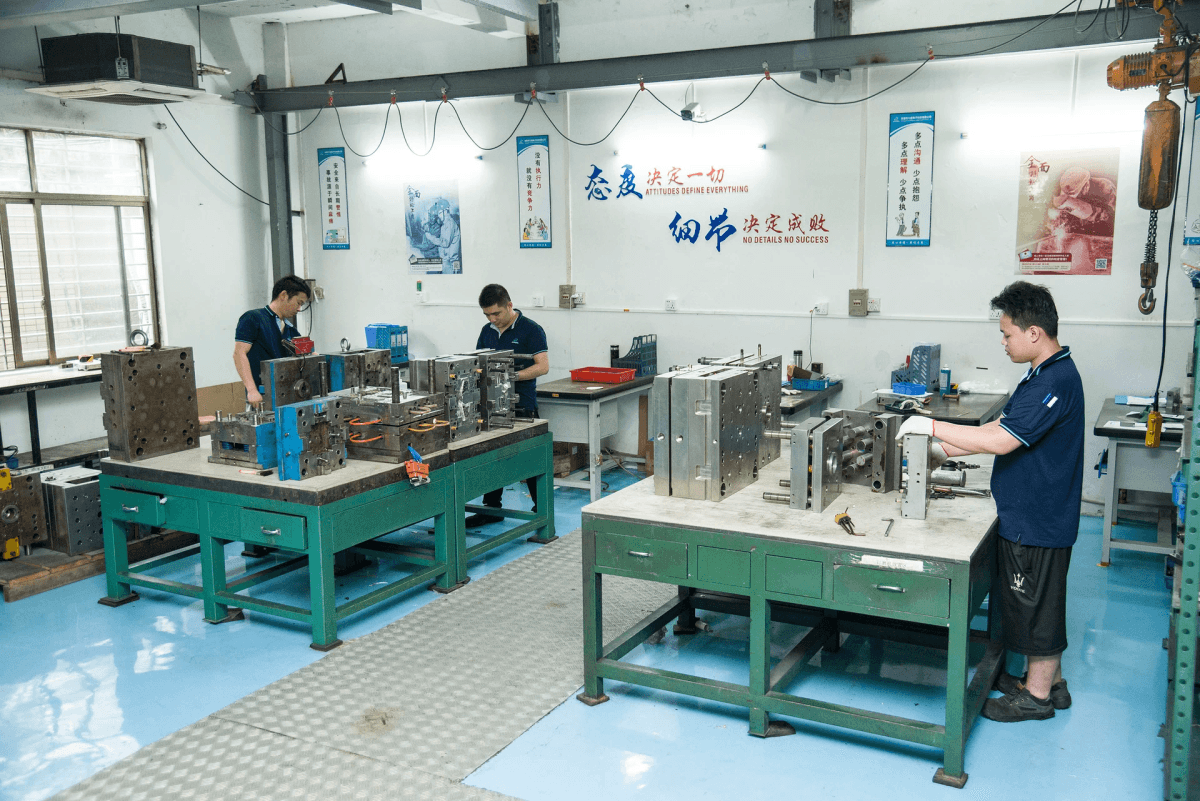

The Role of Baoyuan in Advancing Molding Techniques

Baoyuan stands at the forefront of innovation within the realm of injection molding techniques, driving advancements that enhance productivity while reducing costs. Their commitment to developing cutting-edge solutions aligns perfectly with industry demands for turnkey injection molding services that are both efficient and reliable. By continuously improving technologies related to various types of gates—including hot runner systems and valve gates—Baoyuan ensures that manufacturers are equipped with tools that meet modern challenges head-on.