Introduction

In the dynamic world of manufacturing, finding trusted injection mold components suppliers can feel like searching for a needle in a haystack. With countless plastic molding companies vying for attention, it’s essential to identify those that not only meet your immediate needs but also align with your long-term goals. The right supplier can elevate your production process and ensure that you receive high-quality injection molded parts consistently.

Finding Trusted Injection Mold Suppliers

When it comes to selecting an injection molding partner, the stakes are high. You want a supplier that understands the intricacies of the injection moulding procedure and can deliver custom molding solutions tailored to your specifications. Conduct thorough research on potential mold manufacturers, checking their credentials and industry reputation before making any commitments.

The Importance of Quality Components

Quality components are the backbone of any successful production line; without them, even the best designs can falter. Inconsistent or subpar injection molded parts can lead to costly delays and dissatisfied customers, which is why sourcing from reputable injection mold components suppliers is crucial. Investing time in identifying quality-focused suppliers will pay off in durability and performance over time.

What to Look for in Suppliers

When vetting potential suppliers, consider factors like their experience, technology utilized, and customer service approach. Look for injection molding companies that have a proven track record in delivering reliable products while adhering to strict quality standards. Remember that open lines of communication and responsiveness are key indicators of a supplier's commitment to your success.

Top Injection Mold Components Suppliers

When it comes to injection mold components suppliers, the market is filled with players that offer a wide range of services and products. Understanding who stands out in the crowd can make all the difference in ensuring that your injection molding projects are successful. Here, we highlight three notable companies that have made a significant impact in the field of plastic molding.

Baoyuan: Masters of Custom Molding

Baoyuan has carved a niche for itself as one of the leading custom molding specialists in the industry. Known for their exceptional ability to produce high-quality injection molded parts tailored to specific client needs, they leverage advanced technologies and skilled craftsmanship to deliver results. As a reliable plastic molding company, Baoyuan prioritizes customer satisfaction and consistently meets stringent quality standards throughout the injection moulding procedure.

Their extensive experience with various materials allows them to adapt quickly to changing market demands, making them an invaluable partner for businesses seeking innovative solutions. With a focus on precision engineering, Baoyuan ensures that each mold produced is not only durable but also efficient in terms of production time and cost-effectiveness. If you're looking for injection mold components suppliers who can genuinely understand your unique requirements, Baoyuan should be at the top of your list.

MHS Hot Runners: Innovation in Plastic Molding

MHS Hot Runners stands at the forefront of innovation within the realm of plastic molding technology. They specialize in designing advanced hot runner systems that enhance efficiency during the injection molding process by reducing waste and improving cycle times. This makes them one of those must-consider injection mold components suppliers if you’re aiming for sustainable practices without sacrificing quality.

What sets MHS apart is their commitment to continuous improvement and adaptation within their product lines, ensuring they remain ahead of industry trends. Their solutions not only optimize production but also contribute significantly to reducing operational costs for manufacturers relying on high-volume production runs. For businesses focused on maximizing productivity while maintaining excellence in their molded parts, partnering with MHS Hot Runners is a smart move.

StackTeck: Leaders in Injection Moulding Process

StackTeck has established itself as a leader among mold manufacturers by offering comprehensive services across various sectors including consumer goods, automotive, and medical devices. Their expertise lies not just in creating molds but also in streamlining entire manufacturing processes through innovative design and engineering techniques tailored specifically for each client’s needs. This commitment makes StackTeck one of the most trusted names among injection mold components suppliers.

They utilize state-of-the-art technology combined with years of industry experience to ensure every project is executed flawlessly from start to finish—making sure that every single component meets rigorous quality standards expected from modern plastic molding companies today. Additionally, StackTeck's dedication to sustainability ensures they are always looking for ways to improve efficiency while minimizing environmental impact during production processes—an essential consideration for many businesses today.

Evaluating Supplier Reliability

When it comes to selecting injection mold components suppliers, reliability is key. The right supplier can make or break your production line, especially in the competitive world of plastic molding. Therefore, it's essential to evaluate their reliability through various lenses—experience, quality assurance measures, and customer feedback.

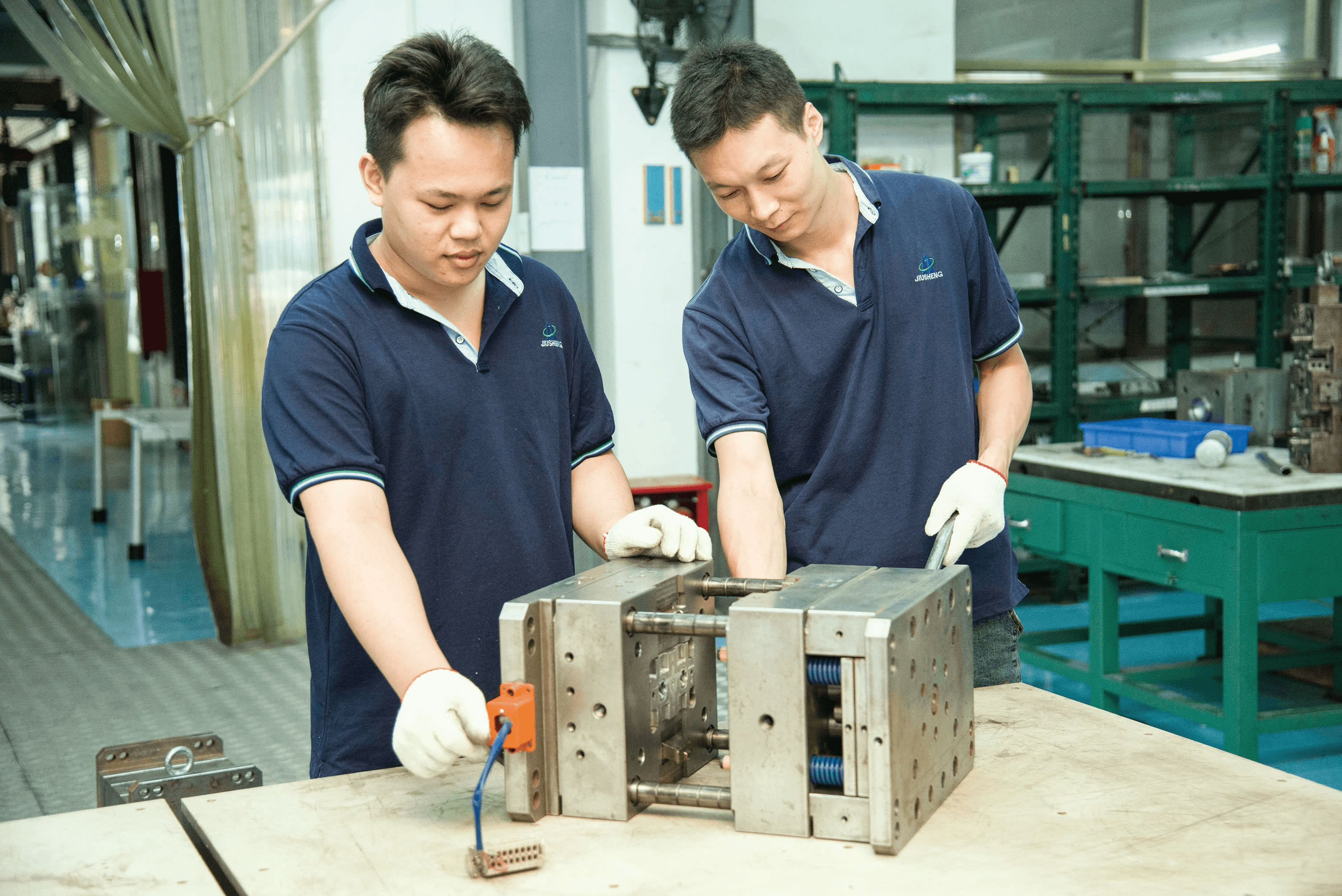

Experience and Expertise in the Industry

A supplier's experience in the injection molding industry speaks volumes about their capability to deliver high-quality products. Established plastic molding companies often have years of hands-on experience, which translates into a deeper understanding of the intricacies involved in custom molding and the injection moulding procedure. This expertise not only ensures that they can handle complex projects but also means they are more adept at troubleshooting any issues that may arise during production.

Moreover, seasoned mold manufacturers typically have a wealth of knowledge about materials and technologies that newer companies might lack. Their familiarity with industry standards helps ensure compliance and quality in every batch of injection molded parts produced. In short, when evaluating suppliers, consider their history and track record; it’s often a reliable indicator of future performance.

Quality Assurance Measures Utilized

Quality assurance is another critical factor when assessing injection mold components suppliers. A robust quality assurance program ensures that each step of the plastic molding process meets strict standards before any product reaches your hands. Look for suppliers who implement comprehensive testing protocols during the entire production cycle—from initial design through to final inspection—to guarantee that their injection molded parts are free from defects.

Additionally, certifications such as ISO 9001 can provide further reassurance regarding a supplier's commitment to quality management practices. Suppliers who prioritize quality assurance are likely to have fewer defects and higher customer satisfaction rates—making them invaluable partners in your manufacturing endeavors. Remember, investing time in understanding these measures can save you headaches down the road.

Customer Reviews and Testimonials

Customer reviews and testimonials serve as invaluable resources when evaluating potential plastic molding companies for your needs. Positive feedback from previous clients can provide insights into a supplier's reliability, responsiveness, and overall performance regarding custom molding projects. By researching online reviews or requesting references directly from suppliers, you can gauge how well they meet expectations consistently.

Conversely, red flags such as recurring complaints about poor communication or product inconsistencies should not be ignored; these could indicate larger issues within the company’s operations or culture that may affect your partnership down the line. Engaging with existing customers through forums or industry events can also provide firsthand accounts of what it's like to work with specific mold manufacturers—information that's often more candid than polished marketing materials might suggest.

In summary, evaluating supplier reliability involves examining multiple facets: their industry experience informs you about their capabilities; quality assurance measures assure you of consistent output; while customer reviews offer real-world perspectives on what working with them entails.

The Role of Technology in Molding

In the fast-paced world of injection molding, technology plays a pivotal role in enhancing efficiency and quality. From sophisticated design software to automated production lines, these advancements are revolutionizing how plastic molding companies operate. Understanding the technological landscape is crucial for anyone looking to partner with reliable injection mold components suppliers.

Advanced Software in Mold Design

The journey of creating high-quality injection molded parts begins with advanced software that streamlines the mold design process. These tools allow mold manufacturers to create precise 3D models, ensuring that every detail is accounted for before physical production starts. By utilizing such technology, custom molding becomes not only faster but also more accurate, significantly reducing the likelihood of errors during the injection moulding procedure.

Moreover, simulation software can predict how materials will behave under various conditions, providing invaluable insights into potential issues before they arise. This proactive approach enables plastic molding companies to refine their designs and optimize performance ahead of time. Ultimately, advanced software enhances collaboration between designers and engineers, paving the way for innovative solutions that meet specific customer needs.

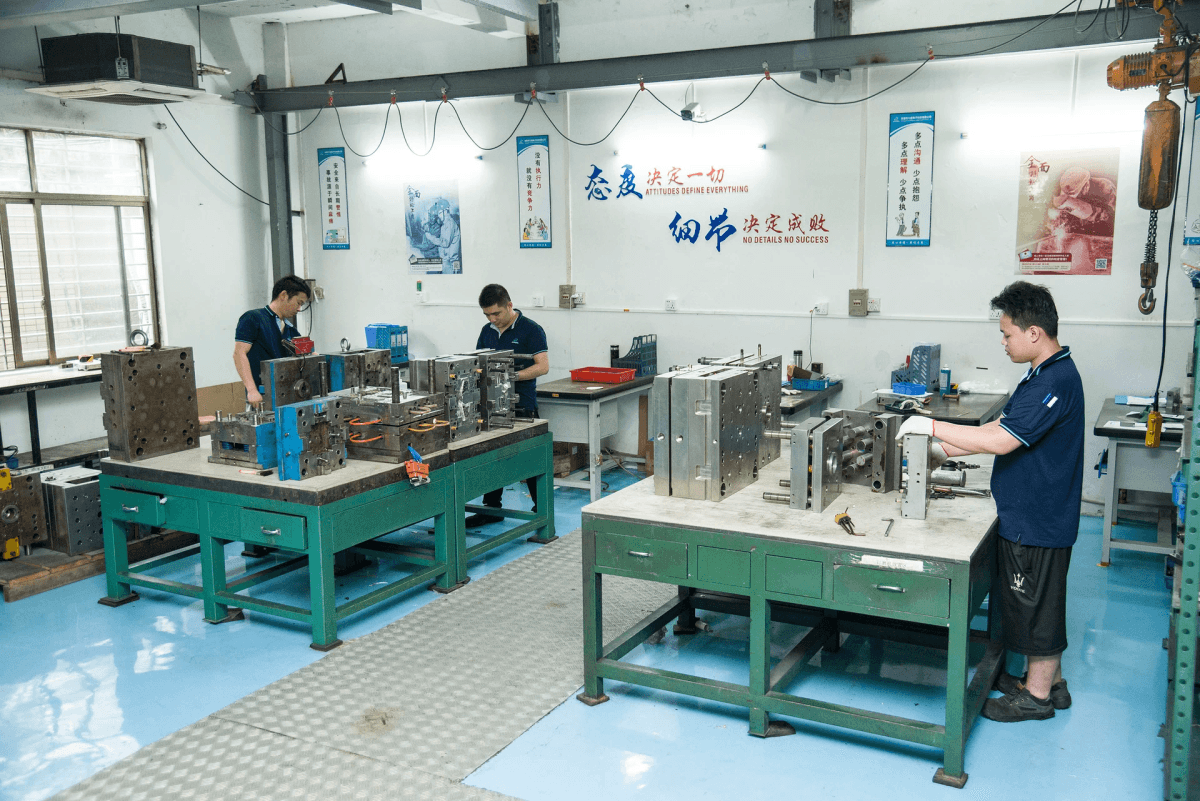

Automation in the Injection Molding Process

Automation is transforming the landscape of injection molding by increasing production speed and consistency while reducing labor costs. Automated systems can handle everything from material feeding to part ejection, allowing plastic molding companies to operate with minimal human intervention. This level of automation not only boosts efficiency but also ensures uniformity across batches of injection molded parts.

Additionally, automated quality control systems utilize sensors and cameras to monitor each step of the injection moulding procedure in real-time. Any deviations from set standards can be detected immediately, allowing for quick adjustments or interventions as needed. As a result, partnering with technologically advanced injection mold components suppliers means you benefit from enhanced reliability and quality assurance throughout your production process.

The Impact of Technology on Quality

The integration of cutting-edge technology into plastic molding processes has a profound impact on product quality and durability. With innovations like precision temperature control and real-time monitoring capabilities, manufacturers can produce more consistent products that meet stringent industry standards. When working with reputable injection mold components suppliers who embrace these technologies, businesses can expect superior outcomes in their projects.

Furthermore, technology facilitates better materials management by optimizing resource usage during production runs—leading to less waste and lower costs overall. This sustainable approach aligns well with current market demands for environmentally friendly practices while maintaining high-quality outputs from custom molding efforts. In essence, leveraging technology not only enhances product quality but also contributes significantly to operational efficiency within the plastic molding sector.

Building Long-Term Supplier Relationships

Building long-term relationships with injection mold components suppliers is essential for the success of any plastic molding operation. A solid partnership not only ensures a steady supply of quality components but also fosters innovation and responsiveness to market demands. By investing in these relationships, companies can enhance their injection molding processes and ultimately improve their bottom line.

Open Communication and Feedback Loops

Open communication is the backbone of successful collaborations with injection mold components suppliers. Regular check-ins, updates on production schedules, and feedback on delivered parts help both parties stay aligned on expectations and requirements. Establishing feedback loops allows for quick adjustments during the injection moulding procedure, ensuring that any issues are addressed promptly before they escalate into larger problems.

Moreover, fostering an environment where both sides feel comfortable sharing insights can lead to innovative solutions tailored to specific challenges in plastic molding. For example, if a particular custom molding technique isn't yielding desired results, open dialogue can lead to brainstorming sessions that produce effective alternatives. Ultimately, this level of communication enhances trust and reliability between businesses and their chosen mold manufacturers.

Importance of Consistent Quality in Parts

When it comes to injection molded parts, consistency is king; there's simply no room for compromise when quality is at stake. Reliable injection mold components suppliers prioritize rigorous quality assurance measures that ensure every part meets industry standards and client specifications. This consistency not only minimizes waste but also significantly reduces production downtime—a critical factor in today's fast-paced manufacturing environment.

Furthermore, consistent quality builds confidence among clients who rely on these parts for their end products. When a plastic molding company can consistently deliver high-quality components, it creates a reputation that attracts new business opportunities while retaining existing customers. As such, maintaining stringent quality control processes should be at the forefront of any supplier's priorities.

Collaborating on Custom Solutions

In an era where customization reigns supreme, collaborating with injection mold components suppliers on bespoke solutions has never been more vital. Many businesses face unique challenges that off-the-shelf products simply can't address; therefore, engaging with skilled mold manufacturers who understand your specific needs can yield remarkable results. Custom solutions not only enhance product performance but also provide competitive advantages in niche markets.

Working closely with your supplier during the design phase allows you to leverage their expertise in custom molding techniques while ensuring your vision comes to life effectively. This collaboration often leads to innovative designs that push the boundaries of what’s possible within plastic molding applications—think cutting-edge materials or intricate geometries that standard molds cannot accommodate! By embracing this cooperative spirit, both parties benefit from enhanced creativity and improved end products.

The Future of Injection Mold Components

The landscape of injection mold components is evolving rapidly, driven by innovation and the need for sustainability. As industries increasingly prioritize environmental responsibility, injection mold components suppliers are adapting to meet these demands. This shift is not only about reducing waste but also enhancing the efficiency of the plastic molding process.

Trends in Sustainable Mold Manufacturing

Sustainable practices are becoming a cornerstone for many plastic molding companies, with a focus on reducing carbon footprints and minimizing material waste. Injection mold manufacturers are investing in eco-friendly materials and processes that promote recycling and reuse of components. By adopting renewable energy sources and optimizing production techniques, these suppliers are paving the way for greener injection molding solutions.

Moreover, sustainable mold manufacturing often leads to cost savings in the long run. Companies can reduce expenses associated with waste disposal and raw material procurement while appealing to environmentally-conscious consumers. As a result, more businesses are seeking out injection mold components suppliers that prioritize sustainability as part of their core values.

Innovations in Material Science for Molding

The future of injection molding is heavily influenced by advancements in material science, which continually introduces new possibilities for creating high-performance parts. Innovative materials such as bio-based plastics and advanced composites are being developed to enhance product durability while reducing environmental impact. These innovations allow plastic molding companies to produce lighter, stronger, and more versatile injection molded parts.

Additionally, research into smart materials—those that can change properties in response to external stimuli—opens up new avenues for customization in the injection moulding procedure. Such developments not only improve functionality but also expand design options available to manufacturers looking to differentiate their products. As a result, collaboration between material scientists and injection mold components suppliers is essential for driving this innovation forward.

The Shift Towards Customization in Production

Customization is rapidly becoming a key trend among consumers who demand unique products tailored to their specific needs. Injection mold manufacturers are responding by offering custom molding solutions that allow clients to specify exact dimensions, features, or even colors for their projects. This shift towards bespoke production methods enhances customer satisfaction while enabling companies to stand out in competitive markets.

Furthermore, advancements in technology have made it easier than ever for plastic molding companies to adapt their processes quickly based on client feedback or market trends. Utilizing advanced software tools helps streamline design iterations while maintaining quality assurance throughout the production cycle of injection molded parts. Consequently, this focus on customization not only meets consumer demands but also fosters long-term relationships between businesses and their trusted injection mold components suppliers.

Conclusion

In the world of injection molding, quality is not just a bonus; it’s a necessity. The precision and durability of injection molded parts hinge on the quality of materials and processes employed by injection mold components suppliers. When you prioritize quality in your projects, you set the stage for success and reliability in your final products.

Why Quality Matters in Injection Molding

Quality plays a pivotal role in the injection molding process, influencing everything from design to production efficiency. High-quality materials sourced from reputable plastic molding companies ensure that the end products meet stringent industry standards and customer expectations. Moreover, superior injection molded parts reduce waste and rework, ultimately saving both time and money in your manufacturing process.

The Benefits of Trusted Supplier Partnerships

Building relationships with trusted suppliers can significantly enhance your production capabilities. Reliable injection mold components suppliers bring experience, innovation, and consistency to the table, which can streamline your custom molding projects. These partnerships not only foster collaboration but also lead to better problem-solving when challenges arise during the injection moulding procedure.

Making Informed Choices for Your Projects

When selecting mold manufacturers for your projects, it’s essential to conduct thorough research and evaluations. Look beyond just price; consider factors like supplier reputation, customer reviews, and technological capabilities to ensure you’re making informed choices that align with your project needs. By prioritizing these aspects, you can secure high-quality outcomes that will benefit both you and your customers in the long run.