Introduction

In the evolving landscape of manufacturing, two prominent techniques stand out: additive manufacturing and injection molding. While both serve essential roles in producing components across various industries, they operate on fundamentally different principles. The question arises: is injection molding additive manufacturing? Spoiler alert: it’s not, but understanding their distinctions can illuminate the best applications for each method.

Defining Additive Manufacturing

Additive manufacturing, often referred to as 3D printing, involves creating objects layer by layer from a digital model. This process allows for intricate designs and rapid prototyping that traditional methods struggle to achieve. In fact, there are multiple types of additive manufacturing techniques; what are the 7 types of additive manufacturing? They range from Fused Deposition Modeling (FDM) to Selective Laser Sintering (SLS), each with unique advantages tailored for specific applications.

The Role of Injection Molding

On the flip side, injection molding is a mass production technique where molten material is injected into a mold to create parts in bulk. This method excels at producing high volumes of identical items quickly and efficiently—ideal for industries such as automotive and consumer goods. So what type of manufacturing is injection molding? It’s primarily categorized as a subtractive process because it shapes materials rather than building them up like its additive counterpart.

Key Differences Explained

The key differences between these two methods lie in their processes and applications; while injection molding focuses on efficiency and uniformity in large-scale production, additive manufacturing shines in customization and rapid prototyping. Understanding these differences can help manufacturers choose the right approach for their projects—whether they need thousands of identical parts or unique prototypes tailored to specific needs. When considering whether to use additive manufacturing vs injection molding, it's crucial to evaluate factors like production volume, material properties, and design complexity.

What is Injection Molding?

Injection molding is a widely used manufacturing process that involves injecting molten material into a mold to create precise and complex shapes. This technique is particularly popular in the production of plastic parts, but it can also be applied to metals and other materials. The ability to produce high volumes of identical parts quickly makes injection molding an attractive option for many industries.

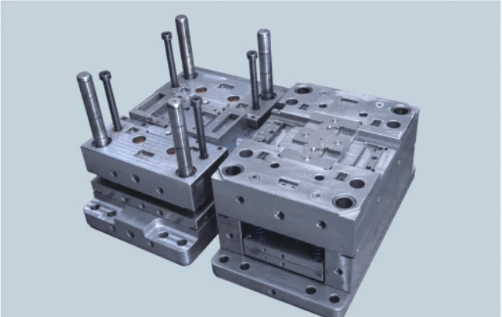

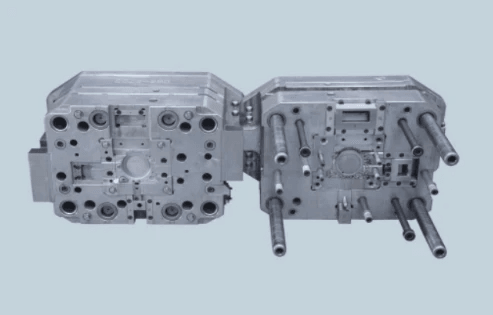

Overview of the Process

The injection molding process begins with heating thermoplastic or thermosetting polymers until they reach a molten state. Once the material is sufficiently heated, it is injected under pressure into a meticulously designed mold cavity where it cools and solidifies into the desired shape. After cooling, the mold opens, and the finished part is ejected—ready for use or further processing.

Injection molding raises an interesting question: Is injection molding additive manufacturing? While both techniques are essential in modern manufacturing, they differ fundamentally in their approaches. Unlike additive manufacturing, which builds objects layer by layer, injection molding relies on creating a negative space that defines the final product's shape.

Common Applications in Industry

Injection molding finds its way into various industries due to its versatility and efficiency. Common applications include automotive components like dashboards and bumpers, consumer goods such as toys and kitchenware, as well as medical devices requiring precision engineering. The ability to produce large quantities while maintaining consistent quality makes injection molding an indispensable method across sectors.

When we ask ourselves what type of manufacturing is injection molding? The answer lies in its classification as a subtractive process rather than additive manufacturing methods like 3D printing or laser sintering. This distinction highlights how products are created differently depending on the chosen technique.

Advantages and Disadvantages

Like any manufacturing method, injection molding has its pros and cons that need consideration before implementation. One significant advantage includes rapid production rates—thousands of parts can be produced in a single day with minimal labor costs involved once everything is set up correctly. Additionally, this method allows for intricate designs that would be difficult or impossible to achieve through traditional machining processes.

However, there are disadvantages too; initial setup costs can be quite high due to mold fabrication expenses, making it less suitable for low-volume production runs compared to additive manufacturing techniques that shine in such scenarios. Furthermore, changes made after molds are created can be costly and time-consuming—another factor that manufacturers must weigh when deciding between additive manufacturing vs injection molding.

In summary, understanding what additives are used in injection molding also plays an essential role in enhancing product performance while addressing specific customer needs across different industries—whether it's improving strength or adding color effects!

Additive Manufacturing Explained

Additive manufacturing, often referred to as 3D printing, is a revolutionary process that creates objects by adding material layer by layer. This contrasts sharply with traditional methods like injection molding, which involve cutting away material from a solid block. Understanding this concept sets the stage for appreciating the unique benefits and applications of additive manufacturing in various industries.

Understanding the Concept

At its core, additive manufacturing builds components from digital models through a series of precise layering techniques. Unlike injection molding, which requires molds and significant upfront costs for production runs, additive manufacturing allows for rapid prototyping and customization without extensive tooling. This flexibility makes it a popular choice for industries looking to innovate quickly and efficiently.

In essence, additive manufacturing is about creating objects directly from computer-aided design (CAD) files. This process enables manufacturers to produce complex geometries that would be impossible or cost-prohibitive using traditional methods like injection molding. As we delve deeper into this topic, it’s crucial to differentiate between these two distinct types of manufacturing.

Types of Additive Manufacturing

There are several types of additive manufacturing techniques that cater to different materials and applications; each has its own strengths and weaknesses. The seven primary types include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), Digital Light Processing (DLP), Binder Jetting, Material Jetting, and Electron Beam Melting (EBM). Each technique varies in terms of material compatibility and application suitability—making it essential to choose the right type based on project requirements.

For instance, FDM is widely used in prototyping due to its affordability and ease of use with thermoplastics. Conversely, SLA offers high-resolution prints ideal for intricate designs but can be more expensive due to resin costs and longer processing times compared to injection molding processes. The versatility among these types ensures that businesses can find an appropriate method tailored specifically for their needs.

Real-World Examples

Additive manufacturing has made significant strides across various sectors—illustrating its potential beyond mere prototypes into fully functional end-use parts. For example, aerospace companies utilize selective laser sintering (SLS) to create lightweight yet strong components that contribute significantly to fuel efficiency in aircraft designs; thus raising questions such as is injection molding additive manufacturing? when discussing production choices in aerospace engineering.

Another striking example lies within healthcare where 3D printing technology enables custom prosthetics tailored precisely to individual patients' anatomy—a feat nearly impossible with traditional methods like injection molding due to mold constraints. Moreover, automotive manufacturers employ additive techniques for rapid prototyping of complex engine components or even entire vehicle structures—showing how versatile this approach can be compared against conventional practices like injection molding.

In summary, while both additive manufacturing and injection molding serve vital roles within modern production environments, they cater distinctly different needs depending on factors such as volume requirements or complexity levels involved in design processes.

The Intersection of Both Techniques

In the world of manufacturing, understanding the intersection between injection molding and additive manufacturing is crucial for making informed decisions. While both processes serve distinct purposes, they also share some similarities that can lead to confusion. By comparing these methods, we can clarify their roles and determine when to leverage each technique effectively.

Comparing Injection Molding and Additive Manufacturing

When we ask, Is injection molding additive manufacturing? the answer is no; they are fundamentally different processes. Injection molding involves creating parts by injecting molten material into a mold, resulting in high-volume production efficiency for complex shapes. In contrast, additive manufacturing builds objects layer by layer from digital files, allowing for more intricate designs but often at a higher cost per unit in low volumes.

The question What type of manufacturing is injection molding? leads us to classify it as a subtractive process rather than an additive one. Injection molding excels in producing large quantities of identical parts quickly and cost-effectively, making it ideal for mass production runs in industries like automotive and consumer goods. On the other hand, additive manufacturing shines when customization or rapid prototyping is required—think unique medical implants or specialized tooling.

Both techniques have their merits depending on the application at hand; however, understanding these distinctions helps businesses choose wisely between Additive Manufacturing vs Injection Molding based on their specific needs.

Analyzing Production Efficiency

Production efficiency is a critical factor when comparing these two methods. Injection molding generally offers superior efficiency in high-volume production scenarios due to its ability to create thousands of identical parts rapidly with minimal waste. This method's speed makes it an attractive option for manufacturers looking to scale production without sacrificing quality or increasing costs significantly.

In contrast, while additive manufacturing may not match injection molding's efficiency in mass production contexts, it provides exceptional flexibility and speed during the design phase—particularly important when developing prototypes or custom parts. For instance, companies can quickly iterate designs using 3D printing technologies without committing to expensive molds upfront. Thus, while injection molding dominates traditional production lines with its efficiency metrics, additive manufacturing fills gaps where rapid iteration and customization are essential.

Ultimately, analyzing production efficiency reveals that each method has unique strengths that cater to different aspects of product development—be it speed or adaptability.

When to Use Each Method

Deciding when to use either technique hinges on several factors including volume requirements and design complexity. If you're producing thousands of units with consistent specifications—like plastic components for consumer electronics—then injection molding should be your go-to choice due to its cost-effectiveness at scale and quick turnaround times after initial setup costs are covered.

Conversely, if you're working on projects that demand unique features or small batch sizes—such as specialized medical devices or custom tooling—additive manufacturing becomes invaluable despite potentially higher unit costs. It allows designers freedom from conventional constraints imposed by molds used in injection molding while enabling rapid changes based on testing feedback.

In summary, understanding the nuances between these two methods empowers manufacturers to make informed decisions about which process best suits their needs at any given moment—a key consideration as industries continue evolving towards more innovative solutions!

The Role of Additives in Injection Molding

Additives play a crucial role in enhancing the performance and functionality of injection-molded products. These substances are mixed with the base polymer before processing, allowing manufacturers to tailor the properties of the final product to meet specific requirements. When discussing whether is injection molding additive manufacturing, it's essential to understand that while they are different processes, additives significantly influence injection molding outcomes.

Common Additives Used

In the world of injection molding, several types of additives are commonly employed to improve material characteristics. For instance, plasticizers enhance flexibility and workability, while stabilizers protect against degradation during processing and use. Other widely used additives include colorants for aesthetic appeal and fillers that reduce production costs by replacing some resin volume without compromising strength.

When exploring what type of manufacturing is injection molding, it's important to note that these additives can also affect how efficiently a product is produced. By optimizing material properties through additives, manufacturers can achieve better flow characteristics during molding, leading to improved cycle times and reduced waste. This versatility makes understanding additives crucial for anyone involved in production processes.

Impact on Product Quality

The impact of additives on product quality cannot be overstated; they can significantly enhance performance attributes such as strength, durability, and thermal stability. For example, flame retardants are added to meet safety regulations without sacrificing structural integrity or aesthetic qualities. Moreover, certain anti-static agents can be incorporated into materials used in electronic applications to prevent dust accumulation or static discharge.

As we delve deeper into additive manufacturing vs injection molding debates, it becomes clear that while both techniques serve unique purposes in manufacturing settings, the right choice often hinges on how well one understands these additive effects on quality outcomes. By employing appropriate additives judiciously, manufacturers can ensure their products not only meet but exceed industry standards—making them more competitive in an ever-evolving market landscape.

Innovations in Additive Injection Molding

Innovations in additive injection molding have emerged as technology advances and market demands evolve. One exciting development is the incorporation of 3D printing techniques within traditional injection molding processes—this hybrid approach allows for complex geometries that were previously difficult or impossible to achieve with standard methods alone. As such innovations continue to develop further blurring lines between traditional methods and what many consider purely additive manufacturing techniques.

Additionally, new types of functional additives are being designed specifically for use within this context—these include bio-based materials which align with growing sustainability concerns across industries worldwide. With ongoing research into smart materials that respond dynamically under different conditions (think temperature-sensitive polymers), we may witness a revolution not just in how we define what type of manufacturing is injection molding but also how we utilize these advancements effectively moving forward.

Expert Insights from Baoyuan

In the ever-evolving landscape of manufacturing, Baoyuan stands out as a beacon of knowledge and expertise, particularly in the realm of injection molding. Their deep understanding of this technique raises an intriguing question: is injection molding additive manufacturing? While both methods are vital in modern production, they serve different purposes and excel in unique scenarios. With years of experience under their belt, Baoyuan has honed their skills to ensure that injection molding remains a leading choice for high-volume production.

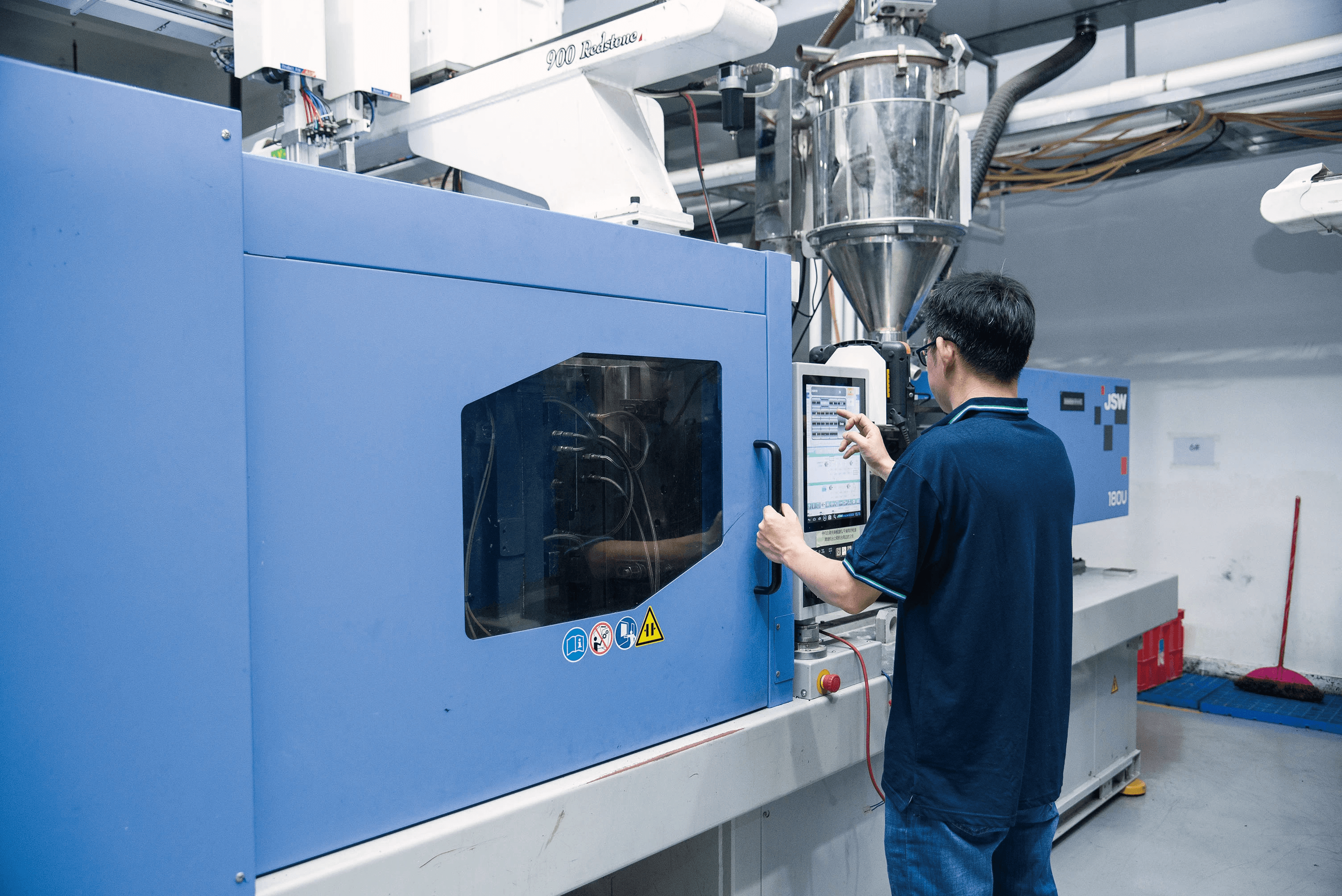

Baoyuan's Expertise in Injection Molding

Baoyuan's expertise in injection molding is rooted in a comprehensive understanding of the process itself and its applications across various industries. This technique involves injecting molten material into a mold to create precise and complex shapes, making it indispensable for mass production. By leveraging advanced technologies and innovative practices, Baoyuan enhances efficiency while maintaining quality—a crucial factor when considering what type of manufacturing is injection molding?

Industry Experience and Quality Assurance

With extensive industry experience, Baoyuan has developed a robust framework for quality assurance that ensures every product meets stringent standards. This commitment to excellence not only builds trust with clients but also elevates their brand reputation within the competitive manufacturing landscape. As they navigate through challenges like fluctuating material costs or evolving consumer demands, Baoyuan continually adapts—highlighting the importance of reliable additives in injection molding that can enhance product performance.

Future Trends in Manufacturing

Looking ahead, Baoyuan recognizes that both additive manufacturing and traditional methods like injection molding will coexist and evolve together. The rise of hybrid techniques combines the best features of both worlds—allowing for customization while benefiting from the efficiency inherent in mass production processes. As we explore future trends, it's essential to understand what are the 7 types of additive manufacturing available today; these innovations could redefine how industries approach design and production strategies.

Conclusion

In the realm of manufacturing, clarity is key, especially when distinguishing between techniques like injection molding and additive manufacturing. While both methods play vital roles in producing high-quality components, understanding their differences can shed light on their applications. This conclusion aims to clarify any confusion surrounding these manufacturing processes and their definitions.

Clarifying the Confusion Around Definitions

When people ask, Is injection molding additive manufacturing? it’s essential to clarify that these are distinct processes with unique characteristics. Injection molding is a subtractive method that involves creating parts by injecting molten material into molds, while additive manufacturing builds objects layer by layer from digital models. Understanding this fundamental difference helps demystify what type of manufacturing injection molding truly represents—it's not additive but rather a traditional subtractive technique.

Key Takeaways on Manufacturing Types

There are several key takeaways when comparing additive manufacturing vs injection molding. First, each method serves different purposes: additive manufacturing excels in prototyping and custom designs, while injection molding is ideal for high-volume production due to its efficiency and cost-effectiveness. Additionally, knowing the seven types of additive manufacturing—such as Fused Deposition Modeling (FDM) and Stereolithography (SLA)—can help businesses choose the right approach based on their specific needs.

Making Informed Decisions on Production Methods

Deciding between injection molding and additive manufacturing requires careful consideration of your project requirements. Factors such as production volume, material properties, and design complexity should guide your choice—whether you lean towards the precision of injection molding or the versatility offered by various types of additive manufacturing. Ultimately, making informed decisions will not only enhance product quality but also optimize costs in your production process.