Introduction

In the world of manufacturing, injection molding stands out as a crucial process for producing high-quality plastic parts efficiently and economically. As industries evolve and demand for precision increases, understanding the landscape of top injection molding companies becomes essential for businesses seeking reliable partners. This guide will explore some of the leading players in the injection molding industry, shedding light on their unique strengths and contributions.

The Importance of Injection Molding

Injection molding is not just a method; it's a cornerstone of modern manufacturing that enables the mass production of intricate plastic components with exceptional accuracy. With its ability to create complex shapes quickly and cost-effectively, it's no wonder that many companies ask, Who is the largest injection molding company in the world? The answer often leads to industry giants that have perfected this art over decades, providing solutions across various sectors from automotive to consumer goods.

Understanding which company is best for an injection molding machine can significantly impact production efficiency and product quality. Leading manufacturers invest heavily in technology and innovation to ensure they remain competitive while meeting diverse client needs. This makes it vital for businesses to align with reputable plastic injection molding manufacturers who prioritize quality assurance and sustainability.

Overview of Top Companies in the Industry

As we delve into this list, we'll highlight some of the top injection molding companies known for their excellence in both machinery and mold production. From established names like Arburg and Engel to rising stars like Tederic Machinery, each company brings something unique to the table. Those looking into who makes the best injection molding machines will find insights on innovative technologies that set these manufacturers apart.

Additionally, we'll explore key players such as Baoyuan, recognized for their expertise in mold design in China—a hub known for producing high-quality molds at competitive prices. By examining these leaders' capabilities and market presence, you’ll gain valuable insights into selecting a partner that aligns with your production goals while ensuring quality outcomes.

What to Expect from This List

Expect a comprehensive overview that not only identifies each company's strengths but also provides context around their contributions to the industry as a whole. This list will cover aspects like technological advancements, specialization areas—like closures or multi-color products—and customer support networks which are critical when choosing among plastic injection molding manufacturers.

In addition to learning about these top companies' offerings, you'll also discover trends shaping the future of injection molding—essential knowledge for anyone involved in manufacturing today. So buckle up as we take you through an exploration of innovation, quality assurance practices, and market leadership within this dynamic field!

Baoyuan

Baoyuan stands out among the top injection molding companies, renowned for its exceptional expertise in mold design and production. With a commitment to innovation and quality, this company has carved a niche for itself in the competitive landscape of plastic injection molding manufacturers. Their advanced techniques and skilled workforce ensure that they not only meet but often exceed client expectations.

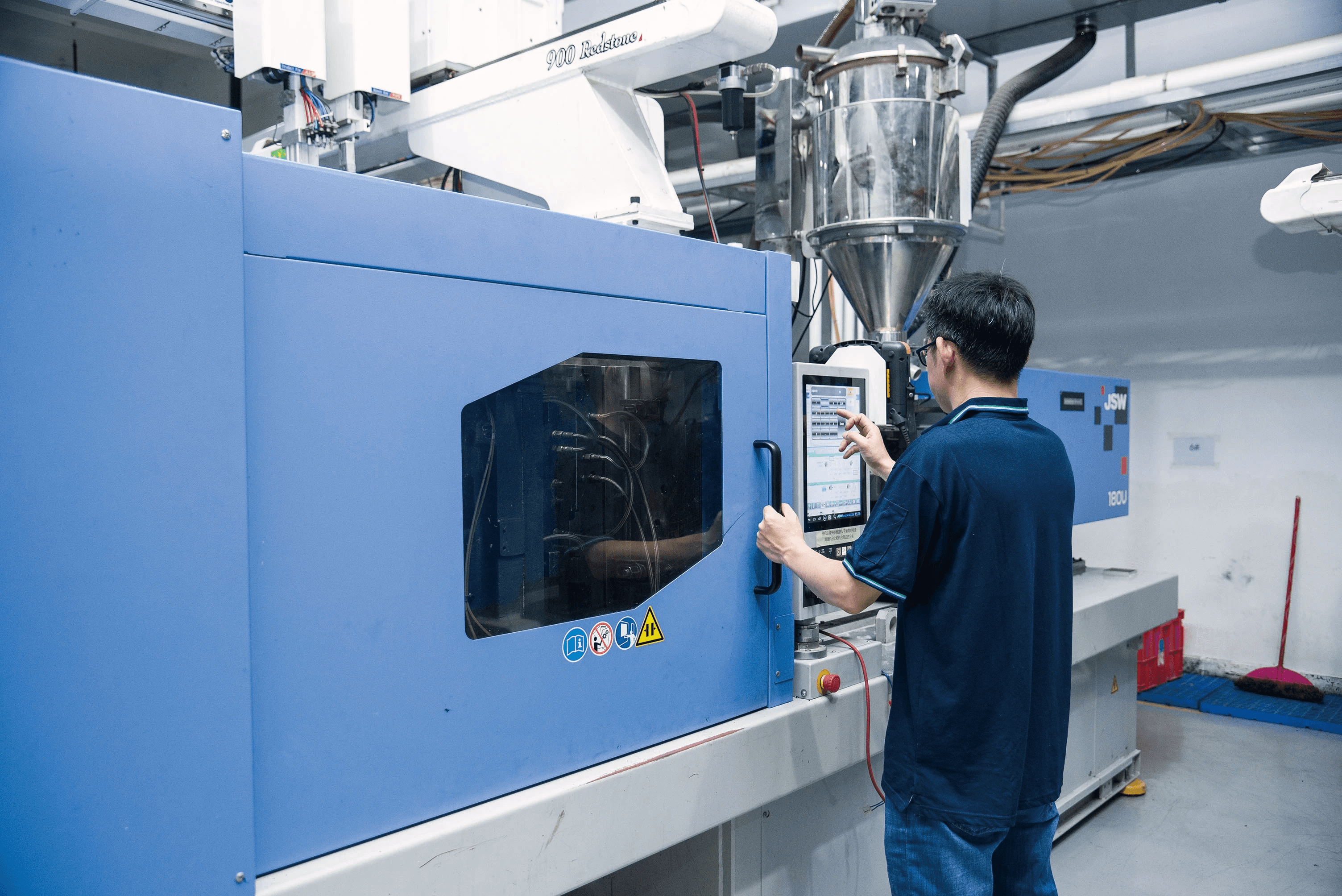

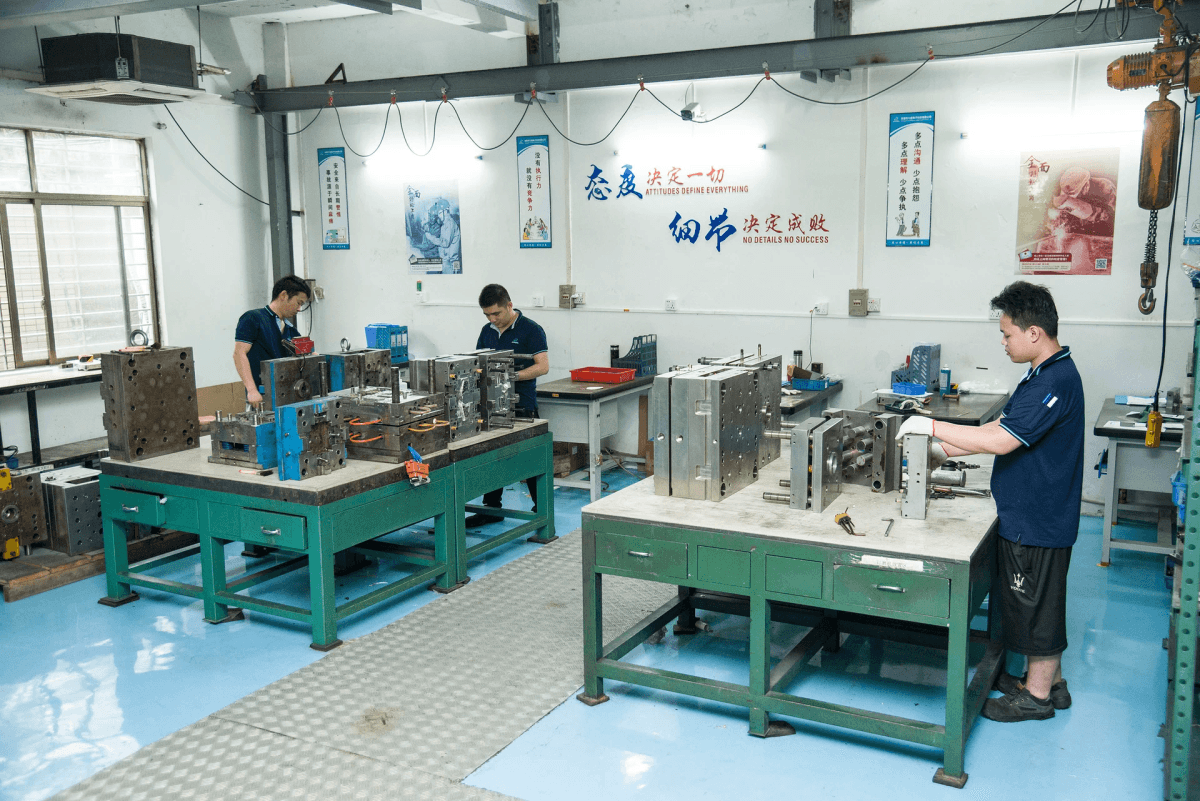

Expertise in Mold Design and Production

At Baoyuan, the expertise in mold design and production is nothing short of impressive. The company employs cutting-edge technology to create molds that are both durable and efficient, making them a favorite among those asking, Who makes the best injection molding machines? Their team of experienced engineers works closely with clients to develop tailored solutions that suit specific needs, ensuring high-quality outcomes every time.

Moreover, Baoyuan's attention to detail during the production process sets them apart from competitors. They understand that precision is key when it comes to creating molds that will be used repeatedly in mass production. This level of craftsmanship has earned them recognition as one of the leading plastic injection molding manufacturers globally.

High Quality Assurance Practices

Quality assurance is at the heart of Baoyuan's operations, making it one of the most reliable names among top injection molding companies. They have established rigorous quality control measures throughout their manufacturing process, ensuring that every product meets international standards. This dedication to quality not only helps them maintain their reputation but also addresses inquiries like Which company is best for an injection molding machine?

Their state-of-the-art testing facilities allow them to assess each mold's performance before it leaves the factory floor. By investing in advanced technology and skilled personnel, Baoyuan guarantees that their products are built to last and perform optimally under various conditions. Clients can rest assured knowing they are partnering with a manufacturer committed to excellence.

Specialization in Multi-Color Products

One area where Baoyuan truly shines is its specialization in multi-color products—a feature increasingly sought after by brands looking to enhance product aesthetics while maintaining functionality. As demand grows for more visually appealing items across various industries, Baoyuan has positioned itself as a go-to provider for multi-color solutions among leading plastic injection molding manufacturers.

Their innovative approach allows clients to achieve vibrant color combinations without compromising on quality or durability. By leveraging advanced technologies and processes tailored specifically for multi-color production, Baoyuan answers questions like Who makes injection molding molds in China? with confidence and flair.

In summary, Baoyuan’s unique blend of expertise in mold design, stringent quality assurance practices, and specialization in multi-color products makes it a formidable player among top injection molding companies worldwide.

Arburg

Arburg stands tall among the top injection molding companies, renowned for its innovative machine technology and commitment to quality. With a legacy that spans decades, this German company has carved a niche in the industry, consistently pushing the envelope on what injection molding machines can achieve. So, who is the largest injection molding company in the world? While various metrics can define largest, Arburg remains a key player in both reputation and technological advancement.

Innovative Machine Technology

At the heart of Arburg's success is its innovative machine technology, which has set benchmarks for efficiency and precision in plastic injection molding. The company's Allrounder series of machines exemplifies their prowess, integrating advanced features such as servo-electric drives and user-friendly interfaces that make operation seamless. When considering which company is best for an injection molding machine, many industry experts point to Arburg for its blend of reliability and cutting-edge capabilities.

Arburg's focus on research and development ensures that they stay ahead of trends, constantly refining their offerings to meet evolving market demands. Their machines are equipped with smart technologies that allow for real-time monitoring and adjustments during production processes, enhancing both quality control and productivity. As a result, they have earned accolades for producing some of the best injection molding machines available today.

Global Presence

With a strong global presence spanning over 100 countries, Arburg is not just another name among plastic injection molding manufacturers; it’s a brand recognized worldwide. Their extensive network of subsidiaries and service partners ensures that customers receive top-notch support no matter where they are located. This global reach also means that clients can trust in consistent quality from one region to another.

The company's international strategy includes participation in major trade fairs like K Fair and Fakuma, where they showcase their latest innovations alongside other top injection molding companies. Such visibility helps them maintain their status as industry leaders while also connecting with potential clients across various sectors. This robust presence allows them to adapt swiftly to local market needs while ensuring high standards are met globally.

Sustainable Manufacturing Practices

Sustainability is increasingly becoming a focal point within the manufacturing sector, and Arburg has taken significant strides toward eco-friendly practices in injection molding operations. They have developed energy-efficient machines designed to minimize resource consumption without sacrificing performance—making them an attractive option for companies looking to reduce their carbon footprint while maintaining productivity levels. When asking who makes the best injection molding machines with sustainability in mind, many would highlight Arburg's commitment to this vital aspect.

Additionally, their initiatives extend beyond just machinery; they actively promote sustainable practices throughout their supply chain by collaborating with other players in the industry to enhance recycling processes and reduce waste generation during production cycles. As more businesses seek partnerships with environmentally conscious manufacturers, Arburg’s dedication positions them favorably among top contenders in this competitive landscape.

In summary, whether you're pondering which company is best for an injection molding machine or exploring options among plastic injection molding manufacturers globally—Arburg consistently emerges as a frontrunner thanks to its innovative technology, extensive international presence, and strong commitment to sustainability.

Engel

Engel is a name synonymous with innovation in the injection molding industry, consistently pushing the envelope with their smart manufacturing solutions. As one of the top injection molding companies globally, Engel has established a reputation for excellence and reliability. Their commitment to integrating advanced technologies into their processes sets them apart from competitors.

Pioneers of Smart Manufacturing

Engel has been at the forefront of smart manufacturing, leveraging Industry 4.0 principles to optimize production efficiency and reduce waste. By incorporating data analytics and automation into their machinery, they help manufacturers make informed decisions that enhance productivity. This innovative approach not only streamlines operations but also positions Engel as a leader among those asking, Who makes the best injection molding machines?

Diverse Industry Applications

The versatility of Engel's machinery allows it to cater to a wide range of industries—from automotive to medical devices—making it a go-to choice for many plastic injection molding manufacturers. Their equipment is designed to meet various application requirements, ensuring that clients receive tailored solutions that fit their specific needs. With such diverse industry applications, it's no wonder people often inquire about which company is best for an injection molding machine.

Commitment to Efficiency

Efficiency is at the heart of Engel's operational philosophy; they strive not just for speed but also for sustainability in their processes. By focusing on energy-efficient designs and practices, Engel helps clients significantly reduce operational costs while minimizing environmental impact—an attractive proposition for businesses today. As inquiries about who is the largest injection molding company in the world continue to rise, Engel’s dedication to efficiency solidifies its position among industry giants.

Husky

When it comes to the realm of injection molding, Husky stands out as a titan among top injection molding companies. With decades of experience under their belt, they have solidified their position as a leader in injection molding equipment, catering to a diverse range of industries. Their innovative solutions and commitment to quality make them a go-to choice for manufacturers worldwide.

Leader in Injection Molding Equipment

Husky boasts an impressive lineup of injection molding machines that are recognized for their reliability and precision. As one of the largest injection molding companies in the world, they have established themselves as a benchmark for excellence in manufacturing processes. Their equipment is designed not just to meet industry standards but to exceed them, ensuring that clients receive nothing short of the best.

Specialization in Closures

One area where Husky truly shines is its specialization in closures, which are critical components across various sectors such as beverage and personal care packaging. Their advanced technology allows for the production of high-quality closure systems that enhance product integrity while also being cost-effective. By focusing on this niche, Husky has become synonymous with top-tier closure solutions within the plastic injection molding manufacturers landscape.

Global Support Network

What sets Husky apart from other top injection molding companies is its robust global support network that ensures customers receive unparalleled service wherever they are located. This network includes dedicated teams that provide on-site training, maintenance services, and technical support tailored to meet specific needs. With such extensive backing, clients can rest assured knowing they have a reliable partner at every step of their manufacturing journey.

KraussMaffei

KraussMaffei stands tall among the top injection molding companies, offering a diverse array of solutions that cater to various industries. Their commitment to innovation and technology sets them apart, making them a go-to choice for manufacturers seeking high-quality injection molding machines. With a reputation for excellence, they have established themselves as a key player in the global market.

Multi-Technology Solutions

KraussMaffei excels in providing multi-technology solutions that encompass not just injection molding but also extrusion and reaction process technology. This versatility allows them to cater to different manufacturing needs, positioning them as one of the best companies for an injection molding machine. Their ability to integrate various technologies means customers can benefit from optimized processes and reduced production times.

Strong Focus on Customization

One of the standout features of KraussMaffei is their strong focus on customization, ensuring that each client receives tailored solutions that meet their specific requirements. This approach is particularly advantageous for businesses looking for specialized molds or unique production setups, reinforcing their status among plastic injection molding manufacturers. By prioritizing customization, they help clients enhance efficiency while delivering high-quality products.

Expertise in Automation

KraussMaffei's expertise in automation is another reason why they are considered one of the largest injection molding companies worldwide. Their advanced automation technologies streamline production processes, reduce labor costs, and improve overall quality control—essential factors for any manufacturer looking to remain competitive. With a keen eye on future trends, KraussMaffei continues to innovate in this area, ensuring they stay ahead of the curve.

Milacron

Milacron stands out among the top injection molding companies, offering a comprehensive product range that caters to diverse manufacturing needs. With a legacy of innovation and quality, this company has established itself as a key player in the injection molding landscape. Their products encompass everything from machines to auxiliary equipment, ensuring that clients find everything they need under one roof.

Comprehensive Product Range

Milacron's extensive array of products makes it a go-to choice for businesses looking for reliable plastic injection molding manufacturers. They provide an impressive lineup of injection molding machines that cater to various industries, ensuring versatility and adaptability in production processes. This comprehensive offering positions Milacron as one of the largest injection molding companies in the world, making it easier for clients to streamline their operations.

Advanced Material Development

In addition to their robust machinery, Milacron is heavily invested in advanced material development, setting them apart from competitors who make injection molding molds in China or elsewhere. By focusing on innovative materials and formulations, they empower manufacturers to produce high-quality parts with superior performance characteristics. This emphasis on material science enhances their reputation as one of the best companies for an injection molding machine.

Emphasis on Customer Service

Milacron understands that customer service is paramount when choosing among the top injection molding companies; after all, no one wants to feel like just another number on a spreadsheet! Their dedicated support team works closely with clients to ensure they maximize their investment and achieve optimal production efficiency. With such commitment to service excellence, it's no wonder many consider Milacron as a leading contender when asking who makes the best injection molding machines.

Nissei Plastic Industrial

When it comes to the top injection molding companies, Nissei Plastic Industrial stands out as a beacon of precision and reliability. This company has carved a niche in the market with its unwavering commitment to high-quality machinery and innovative practices. Whether you're asking, Who makes the best injection molding machines? or looking for a trusted partner, Nissei is often at the forefront of industry discussions.

High Precision Machinery

Nissei Plastic Industrial is renowned for its high-precision machinery that meets diverse manufacturing needs. Their machines are engineered with cutting-edge technology, ensuring accuracy in every cycle. As one of the leading plastic injection molding manufacturers, they continually invest in research and development to enhance their products' performance and efficiency.

The precision offered by Nissei's machines allows manufacturers to produce intricate components that require tight tolerances—an essential factor in industries like automotive and electronics. This level of detail not only boosts product quality but also minimizes waste, making them an attractive choice for companies prioritizing sustainability. If you're pondering Which company is best for an injection molding machine? look no further than Nissei's impressive lineup.

Long Standing Industry Reputation

With decades of experience under their belt, Nissei has built a long-standing reputation that speaks volumes about their reliability and expertise in the field. Many industry insiders would agree that this company's commitment to quality has made it a go-to name among plastic injection molding manufacturers worldwide. Their legacy is not just about producing machines; it's about fostering partnerships that last through consistent performance.

Nissei's reputation isn't just based on historical success; they continue to adapt and innovate according to market demands, ensuring they remain relevant among top injection molding companies today. Clients often share testimonials praising Nissei for their exceptional customer service and support throughout the lifecycle of their products. When you ask Who is the largest injection molding company in the world? while size matters, reputation often holds more weight—and that's where Nissei shines.

Global Manufacturing Footprint

Nissei boasts a global manufacturing footprint that enables them to serve clients effectively across different regions. With production facilities strategically located around the world, they ensure timely delivery and localized support for various markets—making them an appealing choice for international businesses seeking reliable partners in plastic production. This extensive reach also helps mitigate risks associated with supply chain disruptions.

Their global presence means clients can access high-precision machinery regardless of where they operate, which is crucial as industries become increasingly interconnected through globalization. In an era where efficiency matters more than ever, having a partner like Nissei can make all the difference when scaling operations or entering new markets within the realm of top injection molding companies.

BMB S.r.l.

BMB S.r.l. stands out among the top injection molding companies, renowned for its tailored solutions that meet the specific needs of various industries. With a focus on customization, they provide injection molding machines designed to optimize production processes and enhance product quality. Their commitment to flexibility ensures that clients receive solutions that perfectly align with their operational goals.

Tailored Injection Molding Solutions

BMB S.r.l. specializes in creating injection molding solutions that are anything but one-size-fits-all. By understanding the unique requirements of each client, they craft machines and molds that cater specifically to individual production needs, making them a preferred choice among plastic injection molding manufacturers. This level of customization not only improves efficiency but also elevates product quality, solidifying BMB's reputation as one of the best in the industry.

Strong R&D Capabilities

Innovation is at the heart of BMB S.r.l., thanks to their robust research and development capabilities. Investing heavily in R&D allows them to stay ahead of trends and technologies within the injection molding sector, ensuring they produce some of the best injection molding machines available today. Their commitment to continuous improvement means they can adapt quickly to market demands and technological advancements, making them a formidable player among top injection molding companies.

Diverse Clientele

BMB's diverse clientele spans various sectors, from automotive and consumer goods to medical devices and packaging solutions. This breadth allows them to apply their expertise across multiple applications, showcasing their versatility as a leading plastic injection molding manufacturer. By serving such a wide range of industries, BMB not only strengthens its market position but also gathers invaluable insights into emerging trends—keeping them competitive against questions like Who is the largest injection molding company in the world?

Sumitomo (SHI) Demag

Sumitomo (SHI) Demag is a frontrunner among the top injection molding companies, renowned for its innovative approach and compact machinery. Their machines are designed to optimize space without sacrificing performance, making them a favorite for manufacturers looking to maximize efficiency in smaller facilities. With a strong focus on engineering excellence, they consistently deliver machines that meet the diverse needs of their clientele.

Compact Injection Molding Machines

One of the standout features of Sumitomo (SHI) Demag is their range of compact injection molding machines, which are engineered to fit into tight production spaces while maintaining high output quality. These machines are particularly beneficial for businesses that require flexibility without compromising on capability. Their design not only saves valuable floor space but also enhances operational efficiency, making them an attractive option for manufacturers worldwide.

Energy Efficiency Leader

In an era where sustainability is paramount, Sumitomo (SHI) Demag has positioned itself as an energy efficiency leader among plastic injection molding manufacturers. Their advanced technology reduces energy consumption significantly compared to traditional models, which is a game-changer for companies looking to lower operational costs and carbon footprints simultaneously. This commitment to energy-efficient solutions resonates with businesses aiming to align with modern sustainability goals while investing in robust machinery.

Focus on Sustainable Manufacturing

Sustainable manufacturing practices are at the core of Sumitomo (SHI) Demag's operations, reflecting a broader trend among top injection molding companies toward eco-friendly production methods. They prioritize not only the efficiency of their machines but also how these technologies impact the environment throughout their lifecycle. By integrating sustainable practices into their manufacturing processes and offering solutions that promote recycling and reduced waste, they stand out as a responsible choice for those asking who makes the best injection molding machines.

Tederic Machinery

Tederic Machinery has quickly risen through the ranks to become an emerging leader in injection molding, showcasing its prowess among the top injection molding companies globally. Founded with a vision to innovate, Tederic has made significant strides in enhancing the efficiency and capabilities of injection molding processes. Their commitment to quality and technology positions them as a key player in this competitive industry.

Emerging Leader in Injection Molding

As one of the top injection molding companies, Tederic Machinery stands out for its rapid growth and market adaptability. The company has gained recognition for its ability to provide tailored solutions that meet the diverse needs of various industries, including automotive, electronics, and consumer goods. This adaptability is crucial as manufacturers increasingly seek partners who can deliver customized equipment that aligns with their specific production requirements.

Focus on Innovation and Technology

Innovation is at the heart of Tederic’s strategy, making it a formidable contender when discussing who makes the best injection molding machines. The company invests heavily in research and development to create advanced machinery that incorporates cutting-edge technology, ensuring high precision and energy efficiency. By focusing on innovation, Tederic not only enhances productivity but also addresses environmental concerns—making them a popular choice among plastic injection molding manufacturers committed to sustainable practices.

Strong International Reach

With a robust international presence, Tederic Machinery is well-positioned to compete with some of the largest players in the industry when considering who is the largest injection molding company in the world. Their global distribution network allows them to serve clients across various regions effectively while maintaining high standards of customer service and support. This strong international reach helps them cater to an ever-growing clientele looking for reliable solutions from reputable plastic injection molding manufacturers.

Conclusion

In the ever-evolving landscape of manufacturing, understanding the top injection molding companies is crucial for businesses looking to optimize their production processes. From Baoyuan's expertise in mold design to Arburg's innovative machine technology, each company brings unique strengths to the table. As we’ve explored, these industry leaders not only excel in their specific niches but also contribute to advancements that shape the future of injection molding.

Key Takeaways About Leading Companies

One of the standout features among the top injection molding companies is their commitment to quality and innovation. Companies like Engel and Husky have not only established a reputation for reliable equipment but also prioritize efficiency in their manufacturing practices. Additionally, firms such as KraussMaffei and Milacron emphasize customization and customer service, ensuring that they meet diverse client needs across various industries.

So, who is the largest injection molding company in the world? While rankings can fluctuate based on metrics like revenue and market presence, many would argue that companies like Husky lead the pack due to their extensive global support network and specialization in closures. It's essential for businesses seeking partnerships to consider these factors when evaluating potential suppliers.

Insights on Choosing the Right Partner

Choosing the right partner among plastic injection molding manufacturers requires careful consideration of several factors. First, assess your specific needs—whether it's high precision machinery from Nissei Plastic Industrial or tailored solutions from BMB S.r.l., aligning your requirements with a company's expertise is key. Furthermore, look for firms that prioritize sustainable manufacturing practices like Sumitomo (SHI) Demag; this not only reflects corporate responsibility but can also lead to long-term cost savings.

When asking which company is best for an injection molding machine, consider both technological advancements and customer support capabilities. The best partners will offer robust after-sales service alongside innovative machinery solutions—qualities evident in companies such as Tederic Machinery who are making waves with their focus on innovation and international reach.

Future Trends in Injection Molding Industry

Looking ahead, several trends are poised to reshape the injection molding industry significantly. The push towards sustainability will drive more companies toward energy-efficient practices and materials development—a vision already embraced by leading firms like Sumitomo (SHI) Demag and Engel. Moreover, advancements in smart manufacturing technologies promise enhanced automation capabilities across all levels of production.

As we witness these transformations unfold within top injection molding companies, it’s clear that adaptability will be vital for success moving forward. The question remains: Who makes the best injection molding machines? With ongoing innovations from various manufacturers worldwide—including those making molds in China—the answer may vary based on specific applications and regional preferences.