Introduction

In the ever-evolving landscape of healthcare, **injection molding medical** plays a vital role in producing essential components that enhance patient care and improve outcomes. This manufacturing process is not just about creating parts; it's about ensuring precision, safety, and compliance with stringent regulations. As we delve deeper into this topic, we will explore what makes molded components indispensable in the medical field.

Understanding Injection Molding Medical

So, what is medical injection molding? It’s a specialized technique that involves injecting molten plastic into a mold to create various medical devices and components. This process ensures high precision and repeatability, which are critical when it comes to products like surgical instruments or diagnostic devices. With advancements in technology, injection molding has become a cornerstone of modern medical manufacturing.

The Importance of Molded Components

Molded components are crucial for the functionality and reliability of numerous medical applications. From biocompatible implants to intricate surgical tools, these parts must meet rigorous standards to ensure patient safety and efficacy. The significance of these components cannot be overstated; they are often the difference between success and failure in critical healthcare scenarios.

Key Benefits of Medical Injection Molding

The benefits of **medical injection molding** extend far beyond mere production efficiency. For starters, this method allows for mass production with consistent quality—an essential requirement in healthcare where precision matters immensely. Additionally, it offers flexibility in design and materials used; whether you're wondering if is injection molding a good career? or considering how it impacts innovative solutions like injection molding teeth, the advantages are clear: enhanced performance, reduced waste, and lower overall costs.

What is Medical Injection Molding?

Medical injection molding is a specialized process tailored for producing high-quality molded components used in healthcare applications. This method combines precision engineering with advanced materials to create intricate designs that meet stringent medical standards. Understanding what medical injection molding entails is crucial for anyone involved in the healthcare industry, from manufacturers to end-users.

Overview of the Process

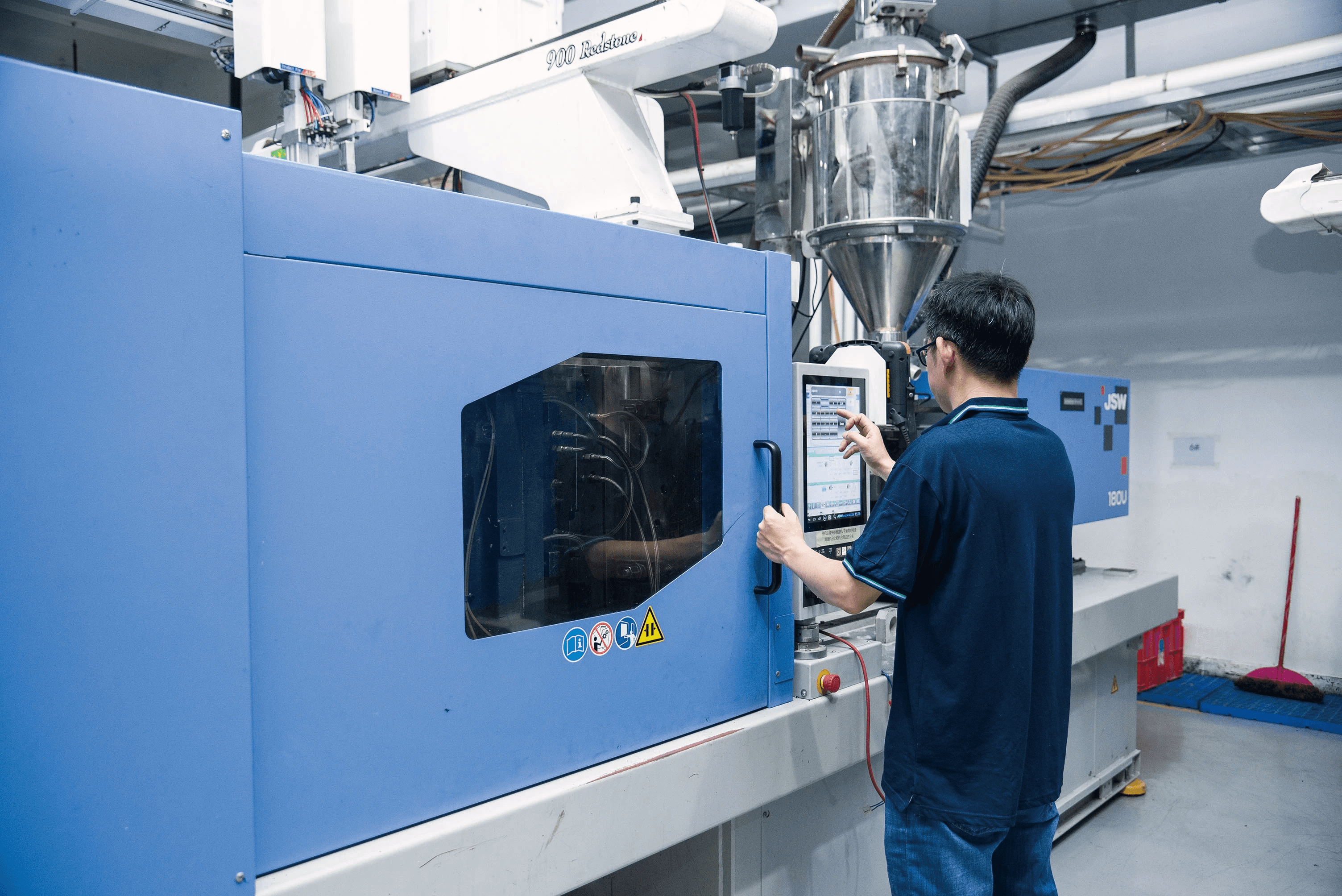

The process of medical injection molding begins with melting plastic pellets and injecting them into a mold under high pressure. This allows for the creation of complex shapes and features that are essential for various medical devices and instruments. After cooling, the molded components are ejected from the mold, ready for further processing or assembly.

One of the key advantages of this method is its ability to produce large volumes of consistent parts efficiently. This efficiency not only reduces production costs but also ensures that each component meets rigorous quality standards essential in healthcare settings. The precision achieved through injection molding medical helps minimize variability, which is critical when safety and efficacy are on the line.

Materials Used in Medical Injection Molding

When it comes to materials used in medical injection molding, biocompatibility is paramount. Common materials include thermoplastics like polycarbonate, polypropylene, and polystyrene—each selected based on their specific properties suitable for various applications. For instance, polycarbonate offers excellent impact resistance while maintaining clarity, making it ideal for diagnostic devices.

Additionally, advancements in material science have led to the development of specialized polymers that can withstand sterilization processes without degrading over time. These innovations ensure that molded components remain safe and effective throughout their lifecycle. As a result, choosing the right material becomes a critical decision point when designing products using injection molding medical techniques.

Comparing Injection Molding with Other Methods

When comparing injection molding with other manufacturing methods such as extrusion or 3D printing, several factors come into play—efficiency being one of them. While 3D printing offers customization options and rapid prototyping capabilities, it often falls short in terms of speed and scalability compared to traditional injection molding processes. For high-volume production runs where consistency is key, injection molding remains unmatched.

Moreover, other methods may not provide the same level of detail or surface finish achievable through injection molding medical processes; this level of precision can be crucial when creating surgical instruments or implants where fit and function are vital. It's also worth noting that while some alternative techniques may be more cost-effective for small batches or prototypes, they often cannot compete with the overall cost efficiency achieved through mass production via injection molding.

In summary, understanding what constitutes medical injection molding reveals its significance within healthcare manufacturing by emphasizing efficiency and quality over alternative methods—a fact worth considering if you're pondering whether is injection molding a good career?

Top Applications of Injection Molding Medical

Medical injection molding is revolutionizing the healthcare industry with its diverse applications. From surgical instruments to biocompatible implants, the molded components produced through this process are critical for enhancing patient care and improving outcomes. Let’s dive into some of the top applications where injection molding medical truly shines.

Surgical Instruments and Tools

Surgical instruments and tools are at the forefront of medical innovation, and injection molding plays a pivotal role in their production. These instruments require precision, durability, and sterility—qualities that molded components can deliver effectively. By utilizing high-quality materials in injection molding medical processes, manufacturers can create tools that meet stringent regulatory standards while ensuring maximum performance during surgeries.

Moreover, the versatility of injection molding allows for complex designs that enhance functionality without compromising safety. For instance, ergonomic handles and specialized tips can be crafted with ease, making surgeries more efficient and less taxing on healthcare professionals. With advancements in technology, surgical instruments made from injection molded materials are becoming lighter yet stronger—a win-win for both surgeons and patients alike.

Biocompatible Implants

Biocompatible implants are another significant application of injection molding medical technologies. These implants must be safe for human use, which means they need to interact positively with body tissues without causing adverse reactions. Injection molding provides a reliable method to produce these critical components with consistent quality and precision.

The ability to customize designs through injection molding also allows manufacturers to tailor implants specifically for individual patients’ needs—think personalized orthopedic or dental solutions! This level of customization is not only beneficial but could also lead to quicker recovery times post-surgery as patients receive implants designed just for them. In addition, innovations in materials used for these molded components continue to evolve, ensuring better integration within the body over time.

Diagnostic Devices

Diagnostic devices represent yet another essential application where medical injection molding excels. These devices often require intricate designs paired with robust functionality—qualities that molded components provide seamlessly. From test kits to imaging equipment housings, effective use of injection molding ensures reliability in diagnostics that can save lives.

In an era where early detection is key in healthcare management, having high-quality diagnostic devices is crucial—and here’s where What is medical injection molding? comes into play as it enables manufacturers to create precise parts rapidly and efficiently. Not only does this streamline production processes but it also supports rapid advancements in diagnostic technologies by allowing quick iterations based on user feedback or technological improvements. As healthcare continues evolving toward more advanced diagnostics solutions, the role of injection molding will undoubtedly expand further.

Innovation in Injection Molding for Healthcare

The landscape of healthcare is rapidly evolving, and injection molding medical technology is at the forefront of this transformation. With advancements in materials and processes, molded components are becoming more sophisticated, efficient, and tailored to meet the complex needs of the medical industry. This section delves into the cutting-edge innovations that are reshaping how we approach healthcare solutions.

Advancements in Technology

Recent advancements in technology have significantly enhanced injection molding medical processes. For instance, incorporating automation and robotics has streamlined production lines, minimizing human error while maximizing efficiency. Furthermore, new materials with improved biocompatibility are being developed, allowing for safer and more effective molded components used in various medical applications.

3D printing technologies also play a pivotal role in revolutionizing injection molding techniques. By enabling rapid prototyping and custom designs, manufacturers can create highly specialized products that cater to specific patient needs. This innovation not only accelerates the development cycle but also opens up new possibilities for personalized medicine.

Additionally, software improvements such as simulation tools allow engineers to predict potential issues before production begins. These tools help optimize designs for injection molding by analyzing factors like flow rates and cooling times, ensuring that what is produced meets stringent quality standards while reducing waste.

Custom Solutions by Baoyuan

When it comes to custom solutions in injection molding medical applications, Baoyuan stands out as a leader in innovation. The company specializes in creating tailored molded components that address unique challenges faced by healthcare providers today. By leveraging advanced technologies and materials expertise, Baoyuan delivers products that not only meet regulatory standards but also exceed customer expectations.

Baoyuan’s commitment to customization means they can adapt existing designs or develop entirely new ones based on client specifications. This flexibility allows healthcare professionals to access precisely what they need—whether it’s surgical instruments or diagnostic devices—without compromising on quality or safety standards associated with injection molding medical practices.

Moreover, Baoyuan places an emphasis on collaboration with clients throughout the design process. By working closely with healthcare teams to understand their specific requirements and constraints, they ensure that each solution is optimized for performance while remaining cost-effective—a win-win for both manufacturers and end-users alike.

Future Trends in Medical Injection Molding

Looking ahead, several trends are shaping the future of medical injection molding that promise even greater advancements within the field. One significant trend is the increasing integration of smart technology into molded components—think sensors embedded into implants or diagnostic devices capable of real-time data collection and analysis. This shift toward smart products will enhance patient monitoring capabilities while improving overall treatment outcomes.

Another trend gaining traction is sustainability within the manufacturing process itself; companies are exploring biodegradable materials as alternatives to traditional plastics used in injection molding medical applications. As environmental concerns grow among consumers and regulators alike, adopting eco-friendly practices will be essential for manufacturers aiming to stay competitive.

Finally, there’s a rising demand for training programs focused on careers related to injection molding medical technologies; many wonder: Is injection molding a good career? Indeed it is! As innovations continue to emerge within this field—especially regarding safety measures against injuries common during production—the job market will likely expand significantly over time.

Safety and Compliance in Injection Molding

In the realm of injection molding medical, safety and compliance are paramount. The complexity of manufacturing medical components requires adherence to strict regulations to ensure product safety and efficacy. This section delves into the regulatory standards, risk management strategies, and quality assurance practices that govern this industry.

Regulatory Standards and Guidelines

When discussing what is medical injection molding, one cannot overlook the regulatory landscape that shapes its operation. Medical devices must comply with stringent guidelines set forth by organizations such as the FDA in the United States and ISO standards internationally. These regulations not only dictate material selection but also mandate rigorous testing protocols to ensure that molded components meet safety requirements before they reach healthcare professionals.

Managing Risks and Injuries in Injection Molding

The question What are the injuries of injection molding? often arises when discussing workplace safety in this field. Common risks include exposure to high temperatures, moving machinery parts, and potential chemical hazards from materials used during production. Implementing comprehensive training programs for employees can significantly mitigate these risks while fostering a culture of safety within facilities that specialize in injection molding medical processes.

Quality Assurance Practices

Quality assurance practices are crucial for maintaining high standards in injection molding medical applications. Regular audits, process validations, and adherence to Good Manufacturing Practices (GMP) help ensure that every component produced meets both regulatory requirements and customer expectations. Moreover, integrating advanced technologies like automation can enhance consistency while reducing human error during production runs of molded components.

Career Opportunities in Injection Molding Medical

The field of injection molding medical offers a wealth of career opportunities for those interested in combining technology with healthcare. As the demand for molded components continues to rise, so do the prospects for professionals skilled in this specialized area. From engineering to quality assurance, there are various paths one can take within this dynamic industry.

Is Injection Molding a Good Career?

Absolutely! Injection molding medical is not just a job; it's a chance to be at the forefront of healthcare innovation. With advancements in technology and an increasing focus on biocompatible materials, professionals in this field are contributing significantly to improving patient outcomes and enhancing medical devices. So, if you're asking yourself, Is injection molding a good career? the answer leans heavily toward yes—especially considering the industry's growth trajectory.

Skills and Qualifications Needed

To thrive in injection molding medical, certain skills and qualifications can set candidates apart from the crowd. A solid foundation in engineering principles is essential, particularly knowledge related to materials science and manufacturing processes like what is medical injection molding? Additionally, familiarity with CAD software and an understanding of regulatory standards will make you more competitive. Strong problem-solving abilities and attention to detail are also crucial for ensuring that molded components meet safety guidelines.

Job Market Insights

The job market for injection molding medical professionals is robust and growing steadily as healthcare technology advances. Companies are seeking individuals who possess both technical skills and an understanding of regulatory compliance within the industry—making it a hotbed for job seekers looking to break into healthcare manufacturing. As new technologies emerge, opportunities will continue to expand across various sectors including surgical instruments, diagnostic devices, and even dental applications like what is injection molding teeth?

Conclusion

As we wrap up our exploration of injection molding medical, it's clear that this technology is not just a manufacturing method but a cornerstone of modern healthcare innovation. With its ability to produce precise and complex molded components, the future looks bright for medical injection molding. As advancements continue to unfold, we can expect even greater efficiencies and capabilities that will enhance patient care and safety.

The Future of Injection Molding Medical

The future of injection molding medical is poised for exciting developments as technology evolves. Innovations such as 3D printing integration, smart materials, and automation are set to revolutionize the way we think about what is medical injection molding? These advancements will not only improve production efficiency but also enhance the customization of molded components tailored to specific patient needs.

Moreover, with the increasing demand for biocompatible materials in healthcare applications, manufacturers will likely invest in research and development to create safer and more effective solutions. The landscape will be shaped by regulatory changes as well, ensuring that safety remains paramount while fostering innovation in injection molding medical practices.

Key Takeaways on Molded Components

When considering molded components in the healthcare sector, several key takeaways emerge from our discussion on injection molding medical. First and foremost, these components are integral to a wide array of applications—from surgical instruments to diagnostic devices—highlighting their versatility and importance in modern medicine. Additionally, understanding what is medical injection molding? allows stakeholders to appreciate its benefits over traditional manufacturing methods.

It's also vital to recognize the potential risks associated with this process; therefore, ongoing education about what are the injuries of injection molding? is crucial for ensuring workplace safety. Ultimately, molded components represent a fusion of engineering excellence and healthcare necessity that cannot be overlooked.

Why Choose Injection Molding for Healthcare Solutions

Choosing injection molding for healthcare solutions comes with numerous advantages that make it an appealing option for manufacturers and practitioners alike. Not only does it allow for high-volume production at reduced costs, but it also offers unparalleled precision—a critical factor when dealing with sensitive medical devices like those used in dental procedures (for example: what is injection molding teeth?).

Furthermore, investing in a career within this field raises an interesting question: Is injection molding a good career? The answer leans toward yes! With promising job market insights revealing an increasing demand for skilled professionals who understand both manufacturing processes and compliance standards within the medical sector.

In conclusion, embracing injection molding medical isn't just about adopting a manufacturing technique; it's about committing to quality care through innovative solutions that meet stringent regulatory standards while enhancing patient outcomes.